Imanuwali yemiyalelo ye-TC55H

Imanuwali yemiyalelo ye-TC55H

Isingeniso Somkhiqizo

I-TC55H inguqulo ethuthukisiwe ye-TC55. Ingakwazi ukulawula izimbazo zokudla ezi-4, i-analog spindle e-1. Ifakwe nezimbobo zokufaka ezingu-16 nezingu-8 zokuphuma, ezisekela ukungenisa files kusuka kunduku ye-USB.

Imininingwane Yezobuchwepheshe

Iyunithi yedatha encane 0.001 mm

Umkhawulo kasayizi wedatha ± 99999.999mm

Isivinini esikhulu: 9000mm/min (ukushaya kwenhliziyo ngu-0.001mm)

Imvamisa yokuphuma kwepulse ephezulu ngu-150KHz

I-Axis 1-4 (X,Y, Z,C)

I-X, Y, Z, C eksisi ingaqhuba ukuhunyushwa komugqa, u-X, u-Y angenza ukuhumusha okuyisiyingi.

Igiya Kagesi: inombolo :1-99999 idinominetha: 1-99999

I-USB: Uhlelo lokungenisa kanye nesithombe sokuqalisa

Imbobo ye-I/O ehlukanisiwe

1000

99

Umugqa Wohlelo Omkhulu:

Uhlelo Olukhulu:

I-RAM: 128M

Ukusebenza Kwemanuwali Kwangaphandle: ukuphotha kwewashi nokuphambene newashi, qala, misa isikhashana,

qaphela futhi ume

Ikhodi ye-G kanye nekhodi engu-M

Iphaneli elilodwa le-MPG

3.5-intshi umbala LCD, pixel 320*240

I-Analog Spindle Output: 1 0-10v spindle ye-analog

Incazelo yoshintsho lwangaphandle

Sicela usithinte uma udinga ukushintsha isithombe sokuqalisa ngaphambi kokuthenga

Ukusebenza

Isikhombo Esiyinhloko

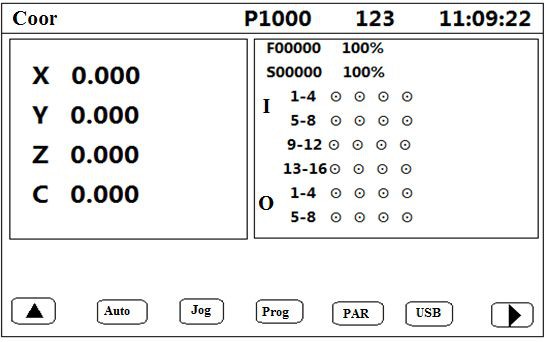

Lesi isixhumi esibonakalayo esiboniswa ngemuva kokuqalisa ngaphandle kwesithombe sokuqalisa. Ibonisa izixhumanisi ze-eksisi ngayinye, isivinini sika-F nezinga, isivinini sika-S nezinga, kanye nesimo sembobo yokufaka neyokukhiphayo. I-P1000 isho uhlelo olusebenzayo njengamanje; 123 kusho indlela yokufaka. Ungangena ku-AUTO, JOG, PROG, PAR, USB kanye nesixhumi esibonakalayo sephasiwedi kusuka lapha.

Okuzenzakalelayo

Ku-Auto Interface, Cindezela okuthi qala ukuze uqalise uhlelo lokugcina lokufunda, Cindezela Misa Misa ukuze Misa.

Isinyathelo

Ukuboniswa okuhle kusho ukusebenza okulandelanayo. Isibonisi esinegethivu sisho umyalo wokusebenza ngomyalo. Uma kuwumbukiso onegethivu, cindezela Qala kanye, kuzokwenziwa umugqa wohlelo owodwa.

Hlela

- Cindezela u-Enter ukuze ufake ulayini omusha.

- Cindezela isikhathi eside okuthi DEL ukuze ususe umugqa.

- Cindezela←→↑↓ukuhambisa ikhesa

- Phezulu: Kulayini wesibhakela

- BTM: kuya kulayini wokugcina

- Isivivinyo: Bheka ukuthi alikho yini iphutha

- Londoloza: Londoloza uhlelo

- Okuzenzakalelayo: Ku-Auto Interface.

Jog

- Cindezela u-X, Y, Z, no-C ukuze ukhethe i-eksisi efanele.

- S yokuzuza izinga lokudla, N yokwehla kwezinga lokudla. (10%-150%)

- G yokuzuza izinga lokuphotha, M yenani lokuphotha elinciphayo. (10%-150%)

- Cindezela okuthi Shift ukuze ushintshe imbobo yokuphumayo, cindezela u-Enter ukuze ushintshe usuka kokuthi VULIWE noma VALIWE.

- Cindezela u-← no-→ ukuze usebenzise ngokulandelana.

- Cindezela u-↑ no-↓ ngokugijima, chaza ibanga lokugijima ku-PAR-Ctrl-Jog+Distance; chaza isivinini sokugijima ku-PAR-Speed-Jog.

Isivinini

Isivinini: Isibonisi esinegethivu sisho isivinini esikhulu mathupha, ukubonisa okuphozithivu kusho isivinini esiphansi mathupha. Cindezela u-← no-→ ukuze usebenzise ngokulandelana.

I-MPG

Cindezela i-MPG, bese uhambisa isondo phezulu, i-eksisi ekhethiwe inyakaze kahle, yehlisa isondo, i-eksisi ekhethiwe inyakaze kabi. Cindezela u-X10X100 ukuze ushintshe inombolo yekhadinali eboniswe phezulu kwesikrini.

| Isimo | Inombolo kaKhadinali |

| X1 | 0.001 mm |

| X10 | 0.01 mm |

| X100 | 0.1 mm |

BPZ

Cindezela lo khiye ku-eksisi ekhethiwe buyela endaweni yesithenjwa ngesivinini esiphezulu. Chaza isivinini esiphezulu ku-Parameters-Speed.

Konke 0

Cindezela lo khiye i-eksisi ekhethiwe ibuyele endaweni yesithenjwa ngesivinini esiphezulu. Chaza isivinini esiphezulu ku-Parameters-Speed. F isivinini esihlanganisiwe sayo yonke i-eksisi.

BMZ

Buyela ku-zero womshini. I-eksisi ekhethiwe izohamba ku-BMZ High Speed ukuze ibuyele ku-zero emshinini, bese ithinta iswishi bese inyakaza ku-BMZ Low Speed, ekugcineni ime eswitch. Ukuze usebenzise lo msebenzi, i-X 0/Y 0/Z 0/C 0 kufanele isethwe ngokuthi “Vuliwe” kokuthi Amapharamitha-Ctrl; Setha i-BMZ High kanye ne-BMZ Phansi kumaParameters-Speed; Setha isiqondiso ku-Parameters-Ctrl-X BMZ

I-Dir

PAR

Ctrl

Lawula indawo yokusetha amapharamitha, Cindezela isikhathi eside u-↑ no-↓ ukuze ushintshe ikhasi.

- I-X/Y/Z/C Numerator: Isilinganiso segiya likagesi (1-99999)

- I-X/Y/Z/C I-Denominator: Isilinganiso segiya likagesi(1-99999)

- X/Y/Z/C Inkomba:Emsebenzini owenziwa ngesandla, cindezela isikhathi eside u-X/Y/Z/C ukuze usule izixhumanisi futhi ubonise leli nani; noma emshinini onguziro, ngemva kokushaya iswishi, izobonisa leli nani.

- Ukuhlehla kwe-X/Y/Z/C: Ukuhlehla emuva ukuze kucace kakhudlwana

- I-X/Y/Z/C I-Boot Zero: 0 isho ukuthi i-eksisi ngeke ibuyele ku-zero womshini ngemva kokuqalisa; 1 isho ukuthi i-eksisi izobuyela ku-zero womshini ngemva kokuqalisa

- I-X/Y/Z/C BMZ Dir: 0 isho i-eksisi ebuyela emuva ku-zero womshini ibheke ohlangothini olunegethivu; U-1 usho ukuthi i-eksisi ibuyela emuva ku-zero womshini iye endaweni eqondile

- Isivinini+Isikhathi(ms): ukusetshenziswa kwesikhathi ukuze injini ifinyelele isivinini sika-F

- I-Jog+Ibanga: ekusebenzeni ngesandla, ukukhuphuka kokugijima. Iyunithi yayo incike esilinganisweni segiya likagesi.

- Ulimi: IsiNgisi (0) noma isiShayina (1)

Ukulungiselelwa kwe-Electronic Gear Ratio

Ukusetha igiya le-elekthronikhi kuwukusetha iyunithi yedatha ehlukene yemishini ehlukene. I-eksisi ehlukene yomshini ofanayo ingasethwa ngokusekelwe kuyunithi ehlukile. Okwesiboneloampi-le, i-eksisi A ingasethwa njenge-mm, i-eksisi B ingasethwa njenge-engeli, futhi i-eksisi C ingasethwa ibe yindilinga.

Usetha kanjani inombolo nedenominator ye-electronic gear ratio:

I-Pulse iyadingeka ukuze injini ijike umzuliswano owodwa iye ohlangothini olufanayo

Ibanga liyahamba lapho injini ijika umzuliswano owodwa iye ohlangothini olufanayo(μm)

Inombolo kanye nedenominayitha kokubili kufanele kube inombolo phakathi kuka-1 no-99999.

Ex. 1 Ukudluliswa kwesikulufa

Ukunyathela kwe-Stepper motor kungu-5000, noma i-servo motor 5000 pulse/round, i-screw pitch ingu-6mm, isilinganiso sokunciphisa ngu-1: 1, bese,

5000 → 5

6*1000*1.0 → 6

Ex. 2 Irakhi kanye nePinion

Ukunyathela kwe-Stepper motor kungu-6000, noma i-servo motor 6000 pulse/round, inombolo yamazinyo egiya ngu-20, m=p/π=2, bese

6000 → 1 → 107 → 107

1000*20*2*3.14159265 → 20.943951 → 2241.00276 → 2241

Ex. 3 I-Rotary Angle

Ukunyathela kwe-Stepper motor kungu-5000, noma i-servo motor 5000 pulse/round, isilinganiso sokunciphisa singu-1:30, bese,

5000*30 → 5

360*1000 → 12

Isivinini

- X/Y/Z/C Highest: Isivinini esiphezulu se-x-axis motor. Uma uhlelo lusebenza, isivinini ngeke seqe le nombolo kungakhathaliseki ukuthi ukusetha u-F kangakanani.

- Qala(mm/min)Isivinini ngesikhathi se-Spd+Time

- I-Man High: Ijubane eliphezulu mathupha

- Indoda Ephansi: Ijubane eliphansi lezandla

- I-BMZ High: Iya ku-zero emshinini ngesivinini esikhulu.

- I-BMZ ephansi: Buyela emuva emshinini onguziro kuqala ngesivinini esikhulu, ngokushintsha ama-zero, ama-es bese ubuyela emuva ngesivinini esiphansi. Ekugcineni, isilayidi sizoma eswishi.

- Imodi ye-BMZ: izindlela ezimbili zokubuyela ku-zero emshinini, ngokusebenzisa iswishi noma cha. Ngokushintsha(0): isilayidi sizoma kuswishi. Not trough switch(1): Isilayidi sizoma ngaphambi kweswishi.

- S High Speed: Isivinini esiphezulu se-spindle

Okokufaka

Lolu hlelo lokusebenza lwenza umsebenzisi akwazi ukusetha amaswishi ahlukahlukene kalula. Chaza imbobo ye-I/O ngokwefomu elilandelayo.

Iswishi enkulu yangaphandle iyadingeka ukuze uqedele ukulawula kwangaphandle. Iswishi yangaphandle ixhunywe ngendlela evamile yokuvula. Cindezela u-R ukuze ushintshe uvule, bese u-S ukhethe CHA(Okuvuliwe Okujwayelekile). Bese ukhetha inombolo Yembobo ye-IO endaweni engenalutho.

Qaphela: Ukuze kucatshangelwe ukuphepha, okokufaka komkhawulo kanye nokumiswa kwezimo eziphuthumayo kuvame ukusetha njengokuthi NC(Vala Okujwayelekile).

| Umsebenzi | Incazelo |

| Isexwayiso | Okokufaka Kwesexwayiso |

| Ima | Okokufaka Kwezimo Eziphuthumayo |

| Gijima | Ngaphandle(Okwangaphandle) Qalisa Isilungiselelo Sokushintsha |

| Misa isikhashana | Ngaphandle(Okwangaphandle) Misa Isikhashana Ukushintsha Isilungiselelo |

| Isivinini+ | Izinga lokuphakelayo likhuphula Ukusetha Ukushintsha |

| Ijubane- | Izinga lokuphakelayo linciphisa Ukusetha Ukushintsha |

| X Lim+ | Ukulungiselelwa komkhawulo we-X-axis Positive |

| X Lim- | Isethingi yomkhawulo we-X-axis Negative |

| X 0 | Isethingi ye-X-axis zero switch |

| Indoda X+ | I-axis ye-X ijikeleza ngaphandle kweswishi eyenziwa ngesandla |

| Indoda X- | I-X-eksisi ephikisana nokujikeleza kwewashi ngaphandle kokushintsha okwenziwa ngesandla |

| I-X Boot Zero | I-X-axis ibuyela kuZiro Womshini ngemva kokuqalisa iswishi yangaphandle eyenziwe ngesandla |

| Y Lim+ | Isethingi yomkhawulo we-Y-axis Positive |

| Y Lim- | I-Y-axis Ukulungiselelwa komkhawulo ongemuhle |

| Y 0 | Isethingi ye-Y-axis zero switch |

| Indoda Y+ | I-eksisi engu-Y ijikeleza ngokuhambisana newashi ngaphandle kweswishi eyenziwa ngesandla |

| Indoda Y- | I-Y-axis ephikisana nokujikeleza kwewashi ngaphandle kokushintsha okwenziwa ngesandla |

| Y Boot Zero | I-Y-axis ibuyela ku- Machine zero ngemva kokuqalisa iswishi yangaphandle eyenziwa ngesandla |

| Z Lim+ | Ukusetha umkhawulo we-Z-axis Positive |

| Z Lim- | I-Z-axis Ukulungiselelwa komkhawulo ongemuhle |

| Z0 | Ukulungiselelwa kokushintshwa kwe-Z-axis zero |

| Umuntu Z+ | I-axis engu-Z ijikeleza ngaphandle kweswishi eyenziwa ngesandla |

| Umuntu Z- | I-Z-axis ephikisana nokujikeleza kwewashi ngaphandle kokushintsha okwenziwa ngesandla |

| I-Z Boot Zero | I-Z-axis ibuyela ku-zero Machine ngemva kokuqalisa iswishi yangaphandle eyenziwa ngesandla |

| C Lim+ | I-C axis Ukusetha umkhawulo omuhle |

| C Lim- | I-C axis Ukusetha umkhawulo ongemuhle |

| c0 | Isilungiselelo sokushintsha i-axis zero engu-C |

| Umuntu C+ | I-axis engu-C ijikeleza ngaphandle kweswishi eyenziwa ngesandla |

| Umuntu C- | I-C axis ngokuphikisana nokuhamba kwewashi ukuphotha ngaphandle kokushintsha okwenziwa ngesandla |

| C Boot Zero | I-C axis ibuyela ku-zero Machine ngemva kokuqalisa iswishi yangaphandle eyenziwa ngesandla |

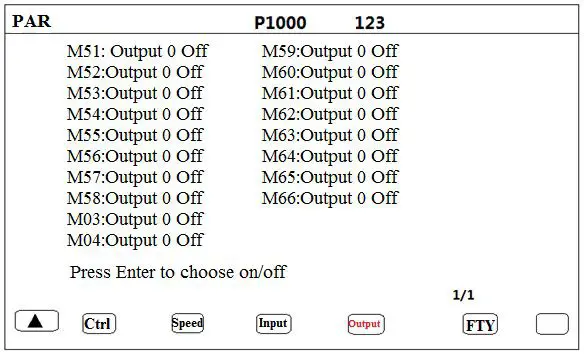

Okukhiphayo

Kulesi sikhombimsebenzisi ukuchaza ukuvula nokuvalwa kwamachweba okukhiphayo angu-1-8, ungasebenzisa ngokuqondile ukuhlela. I-M03-M04 i-spindle interlock.

I-FTY

Buyela emuva kunani lasembonini.

Ukusebenza

- Cindezela u-←→↑↓ukuhambisa ikhesa

- Cindezela isikhathi eside ↑↓ukushintsha ikhasi

- Ngemva kokushintsha amapharamitha, cindezela u-ESC, nali iwindi livela libuza ukuthi londoloza amapharamitha noma cha, cindezela u-Enter bese ulondoloza, cindezela u-ESC noma Ungayeki ukulondoloza.

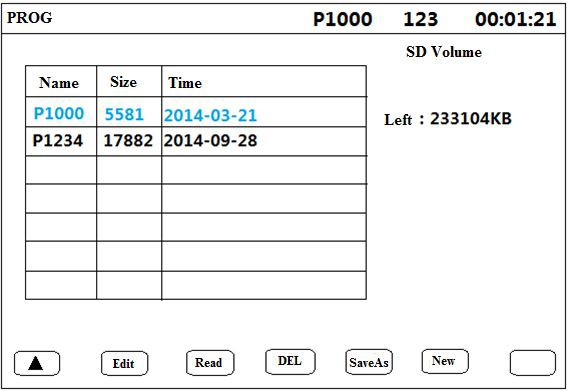

Inqubekela phambili

Kulesi sixhumanisi ukuhlela, ukufunda, ukususa, ukulondoloza nokudala uhlelo files.

I-USB

- Igama Lohlelo: P123.TXT noma P1234. I-TXT

- Igama Lesithombe Sokuqalisa: K123.bmp noma i-K1234.bmp Pixel: 320*240

13811674107 jiafengqi.xtf@hotmail.com

Amadokhumenti / Izinsiza

|

I-TOPCNC TC55H CNC Isilawuli [pdf] Incwadi Yeziqondiso I-TC55H, Isilawuli se-CNC |