danfoss Ibhokisi lamathuluzi le-JIP-Hot Tapping Machine

Imiyalo yokuphepha

Umsebenzisi welulekwa kahle ukuthi alandele imiyalelo yokuphepha enikezwe kuleli bhukwana. Asikho iwaranti enikeziwe ngokusetshenziswa okungalungile kwezinto zokusebenza noma izinhlelo zokusebenza ezingaphandle kobubanzi be-Uma noma yimiphi imibuzo evela noma uma ungenasiqiniseko mayelana nezici ezithile mayelana nebhokisi lamathuluzi lomshini oshisayo we-Danfoss, sicela ungangabazi ukuxhumana ne-Danfoss yendawo ukuze uthole ukwesekwa.

Izidingo ezijwayelekile zokuphepha

Ezahlukweni ezilandelayo, imiyalelo evamile neqondile ye-saftey yebhokisi lamathuluzi lomshini wokudonsa oshisayo we-Danfoss inikezwa futhi ichazwe. Umsebenzisi welulekwa kahle ukuthi afunde, aqonde futhi alandele le miyalo ngokucophelela. Umuntu oqeqeshiwe kuphela noqeqeshiwe ovunyelwe ukwenza imisebenzi yokuthepha okushisayo ngethuluzi le-Danfoss lokuthepha okushisayo. Phakathi kwama-opharetha, kufanele kube nohlelo lokulawula ukuqinisekisa ukuthi amakhono nolwazi lwezinqubo zokusebenza ezifanele ziyaziwa futhi zihlonishwa yibo bonke abantu abasebenzayo ababamba iqhaza emisebenzini ye-hot tapping. Le manuwali yomsebenzisi kufanele ihlale ikhona ngesikhathi sokumba. Akuvunyelwe ukusebenzisa idivayisi ngaphandle kwendawo yohlelo lokusebenza echazwe kuleli bhukwana lomsebenzisi ngaphandle kwemvume yomkhiqizi wedivayisi yebhokisi lamathuluzi wokuthepha okushisayo i-Danfoss. Qaphela ukuthi izidingo ezengeziwe zinganikezwa endaweni ethile yokusebenza.

Ukuze kusetshenziswe ngendlela ephephile okokusebenza kubalulekile ukunaka amaphuzu ajwayelekile alandelayo. Ungalokothi usebenzise umshini ngaphandle kokuqaphela izingozi. Cabangela zonke izici ezivela kuleli bhukwana lomsebenzisi kanye nezimfuneko ezengeziwe.

- Abasebenzi kumele babe namakhono anele nokuqeqeshwa kuzo zonke izigaba ezidingekayo zomsebenzi wokushaya okushisayo kanye nokuphatha imishini okukhulunywa ngayo.

- Qiniseka ukuthi uhlala unekhophi yale manuwali yomsebenzisi nawe etholakala phakathi nenqubo yokuthepha okushisayo.

- Imiyalo ingalandwa kumkhiqizi webindawo http://www.danfoss.com

- Indawo esetshenziswayo yalolu cingo ikhawulelwe kuketshezi oluwuketshezi olususelwa emanzini lweqembu 2 ngokuya nge-PED 2014/68/EU.

- Amapharamitha wesistimu akumele eqe ku-200 °C kanye/noma amabha we-40 wokucindezela. Bheka isahluko 3 mayelana nezinga lokushisa eliphezulu nokucindezela lolu cingo olungasetshenziswa.

- Kunconywa ukunciphisa ukucindezela ohlelweni ku-bar ye-12 ngesikhathi sokusebenza.

- Qinisekisa ukuthi i-adaptha ekhethiwe kuhlanganise nokuvala uphawu ifanele ingcindezi yesistimu, uhlobo loketshezi kanye nezinga lokushisa.

- Njalo qiniseka ukuthi okokusebenza awonakele ngaphambi kokuqala inqubo yokuthepha okushisayo. Imishini kuphela esesimweni esihle kakhulu okufanele isetshenziswe.

- Sebenzisa kuphela izingxenye ezisele ze-Danfoss zoqobo ukuze uphephe.

- Gqoka ukuvikela indlebe nesigqoko sokuzivikela.

- Gqoka izingubo zokusebenza ezifanele.

- Ungagqoki izingubo ezixegayo noma ubucwebe njengoba zingabanjwa izingxenye ezihambayo.

- Ukuze uvikeleke oketshezini olushisayo, gqoka izingubo ezikwazi ukumelana nokushisa, amagilavu kanye nezibuko zokuphepha.

- Noma yiluphi ushintsho lobuchwepheshe emshinini wokuthepha oshisayo aluvunyelwe.

- Cabangela imithethonqubo evamile yokuvimbela izingozi.

- Qaphela imiyalelo yemishini eshayelwa yimoto.

- Cabangela izingozi ezivela kugesi kanye nezingxenye ezijikelezayo ezinamathiselwe ku-A1.

- Idrayivu kagesi ayisoze yaba manzi.

Izidingo Zokuphepha Esizeni Sokusebenzela

Izici ezilandelayo kufanele zihlolwe ngaso sonke isikhathi endaweni yokusebenza ngaphambi kokusebenzisa idivayisi yokumba i-Danfoss. Ngokumba amapayipi okushisisa wesifunda eJalimane, kufanele kucatshangelwe umyalelo we-AGFW 432.

- Ngaso sonke isikhathi qiniseka ukuthi kuyenzeka ukuvala i-valve ye-Hot Tap ekhethiwe.

- Uma indlela yokuvala ingakwazi ukuvalwa, ukuphela kwendlela yokukhipha idivayisi yokubhoboza ukukhipha umugqa oyinhloko.

- Hlola kabili usayizi wesaha yembobo esetshenzisiwe kanye ne-pilot drill. Hlola ukuthi i-valve iyavaleka ngemva kokuhlanganiswa komshini.

- Zijwayeze ishidi ledatha le-Danfoss lohlobo lwevalvu ekhethiwe

- Qiniseka ukuthi amapharamitha wobuchwepheshe (ingcindezi, izinga lokushisa, uketshezi) ohlelweni aweqi amanani avunyelwe ohlelo oluthile.

- Hlola ukuthi idivayisi ihlanganiswe ngendlela efanele yini njengoba kuboniswe kuleli bhukwana lomsebenzisi

- Njalo yenza ukuhlolwa kwengcindezi ukuze uthole ukuvuza okungase kube khona kuvalvu yokuvala kanye/noma kudivayisi yokubhoboza

- Qinisekisa ukuthi zonke izingxenye ezijikelezayo zihamba ngokukhululeka

- Hlola idivayisi ngokohlelo lokuhlola.

- Abantu abangagunyaziwe akufanele babe khona endaweni yokusebenza ngesikhathi sokushaywa okushisayo

- Hlola indawo yevalvu yokuvala inethiwekhi eseduze endaweni yokusebenza

- Qiniseka ukuthi uyabazi bonke oxhumana nabo besimo esiphuthumayo.

- Lokhu kuthinta abantu othintana nabo kusayithi, othintana naye kumkhiqizi wedivayisi ye-TONISCO System (http://www.tonisco.com) kanye nabezimo eziphuthumayo zendawo

- Yenza isheke elibonakalayo lendawo yokusebenza futhi uthathe zonke izilinganiso ezidingekayo.

- Hlanza indawo yokusebenza kuzo zonke izinto ezingadingekile.

- Cabangela isikhala esidingekayo ukuze kukhishwe shaft ngemva kokumba

- Qinisekisa ukuthi wonke amathuluzi adingekayo kanye nemishini ayatholakala ngenkathi ubhoboza isb. chain block lapho kunengcindezi ephezulu.

Izingozi Ezikhethekile

Ukukhishwa Kwamanzi Ashisayo noma I-Steam

Amanzi ashisayo noma isitimu kungase kubaleke isistimu ngenxa yokungaphathwa kahle. Qinisekisa ukuthi ugqoka izinto zokuphepha ezinqunyiwe uma usebenza ngomshini oshisayo.

Uma ukhulula ukucindezela okuvela kudivayisi yokumba, qiniseka ukuthi ugcina ibanga elanele phakathi kwakho nepayipi lokukhulula. Gqoka njalo amagilavu okuvikela ukumelana nokushisa lapho ukhipha umshini wokumba kuvalvu.

Izingozi Ezisuka Ezingxenyeni Ezishintshayo

Qaphela ukuthi i-drill shaft kanye nezingxenye zokushayela ziyajikeleza ngesikhathi sokumba. Qaphela izinguquko ze-torque ku-shaft ngenxa yamandla okusika ahlukahlukene.Thatha ukuma okugxilile bese uphendulela okuphakelayo kancane kancane. Uma isaha lembobo libhajwa ngesikhathi sokubhoboza, yehlisa isivinini sokuphakela noma jikisa isondo kancane emuva kuze kube yilapho isaha lembobo likwazi ukuzungeziswa futhi.

Izingozi Ezidalwa Ingcindezi Emapayipini

Isikhathi esiningi kuba nengcindezi ekhona epayipini elibhojwayo. Kunconywa ukunciphisa ukucindezela ohlelweni ku-bar ye-12 ngesikhathi sokusebenza.

Uma ingcindezi ku-mainline ingu-> 12 bar kunconywa kakhulu ukusebenzisa i-chain block ukuze kukhululwe ngokuphephile shaft yokumba. Le ngxenye ayifakiwe ebhokisini lamathuluzi kodwa ingathengwa kwa-Danfoss njengesisetshenziswa.

Izimfuneko ze-Operator

Umshini wokuthepha oshisayo ungasetshenziswa kuphela abantu abaqeqeshiwe, abayaliwe futhi abagunyazwe ukuwusebenzisa. Umsebenzisi kufanele azi imiyalelo yokusebenza futhi enze ngokufanele.

Ukubaluleka Kwezimpawu ezisetshenzisiwe Ukuphepha

ISEXWAYISO

Ixwayisa ngokulimala okubi okungenzeka noma ukufa. uma imiyalelo ingagadiwe.

ISEXWAYISO

Ibonisa ukulimala okungenzeka komuntu siqu noma ukulimala, uma imiyalelo ingagadiwe.

I-Danfoss Hot Tapping Machine Toolbox

Indawo Yokusetshenziswa

Umshini wokuthepha oshisayo we-Danfoss uhloselwe ukufeza amagatsha amapayipi amasha ngaphansi kwengcindezi kuzinhlelo zokushisisa nokupholisa okusekelwe emanzini kubukhulu begatsha DN15 – DN100. Umzimba wedivayisi yokumba i-Danfoss yakhelwe ukucindezela okukhulu kwamabha angu-40 futhi ingasetshenziswa njengoba kuchazwe etafuleni elingakwesokudla kwekilasi PN40. Kodwa-ke, ngengcindezi > amabha ayi-12 izidingo ezengeziwe zokuphepha kufanele zicatshangelwe lapho ukhulula shaft noma ulungisa okuphakelayo.

Imininingwane ye-Danfoss Hot Tapping Toolbox

Umzimba wedivayisi uqukethe ukutywinwa kwe-EPDM. Ebhokisini lamathuluzi le-Danfoss, iyunithi yokushayela kagesi ifakiwe. Le manuwali yomsebenzisi igxile kuyunithi yokushayela kagesi i-Metabo BE1100 ngokucaciswa okulandelayo kobuchwepheshe

| Igama Ledivayisi Yokubhoboza | I-Metabo BE 1100 |

| Impahla Yomzimba | 42CrMo4 |

| Inombolo Yomkhiqizo | 1200.0000 |

| Ukumaka | Bxx xx= Id. ngeNyanga, Unyaka |

| Isigaba acc PED 97/23/EG | 1 |

| Ubukhulu begatsha | I-DN 15 kuya ku-DN 100 |

| Indawo Yokusetshenziswa | Amasistimu wokushisisa nokupholisa asekelwe emanzini |

| I-Agregate State of the Fluid | uketshezi |

| I-Max Working Pressure | 40 ibha |

| Ukucindezela okukhulu okunconyiwe | 12 ibha |

| Ingcindezi Yokuhlola | 60 ibha |

| Ukushisa Okuphezulu Okusebenzayo | 160 °C |

| Izinga Lokushisa Elincane Lokusebenza | 0 °C |

| Ukubekwa uphawu | I-EPDM |

| I-Drill Shaft | insimbi eqinile Ø20 mm |

| Isisindo Ngaphandle KweDrayivu | 5,4 kg |

| Isondo lokuphakelayo Ibanga | 50 mm |

| Ibanga eliphezulu lokuphakelayo | 150 mm |

Ibhokisi lamathuluzi le-JIP Hot Tapping Machine

I-Danfoss JIP Hot Tap Valves yokuthepha Okushisayo

Umshini wokumba kufanele usetshenziselwe ukubhola amaValves e-Danfoss JIP Hot Tap Ball ebangeni elisuka ku-DN15 ukuya ku-DN100 nasezinhlelweni zokushisisa nokupholisa ezisekelwe emanzini. Ukuxhumana phakathi komzimba womshini kanye nevalvu kubonakala ngezicucu ze-adaptha ezinentambo. Ezinye izingcezu ze-adaptha zisetshenziselwa usayizi ongaphezu kowodwa ngokusebenzisa ukuncishiswa kwe-adaptha

isisekelo. Wonke ama-adaptha aklanyelwe ukusetshenziselwa kuphela ama-Danfoss JIP Hot Tap Valves. Khumbula ukulawula ukucindezela okuvunyelwe kanye nezinga lokushisa acc. isahluko 3.1 nokulandela Danfoss JIP Hot tap ibhola amavalvu idatha sheet.

|

Izinguqulo ze-valve ezijwayelekile |

|||||||||

| DN | mm | 15/20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

| PN | 40 | 25 | |||||||

| Idayamitha yesaha yembobo | mm | Ø15 | Ø24 | Ø24 | Ø40 | Ø40 | Ø48 | Ø65 | Ø79 |

| Inombolo yekhodi. | 065N0050 | 065N0051 | 065N0052 | 065N0053 | 065N0054 | 065N0055 | 065N0056 | 065N0057 | |

|

Ibhokisi lamathuluzi Ikhodi No. |

065N1021 | – | |||||||

| 065N1003 | 065N1004 | ||||||||

| 065N1002 | |||||||||

OEM valve izinguqulo |

||||

| DN | mm | 20 | 25 | 40 |

| PN | 40 | |||

| Idayamitha yesaha yembobo | mm | Ø19 | Ø32 | |

| Ikhodi Cha | 065N0070 | 065N0071 | 065N0072 | |

| Ibhokisi lamathuluzi Ikhodi No | 065N1022 | 065N1023 | ||

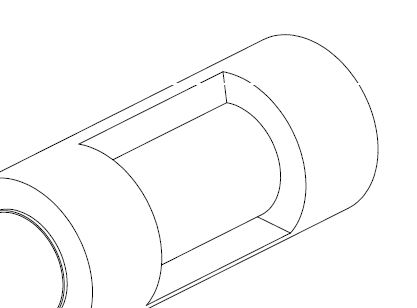

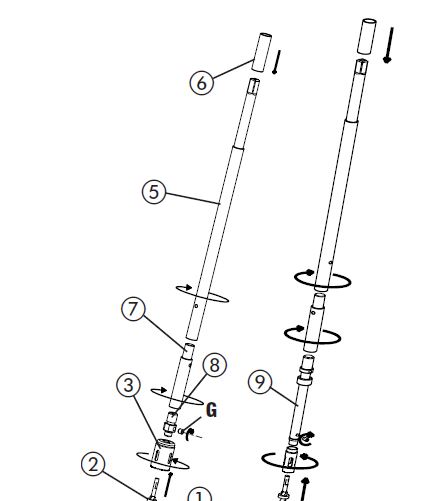

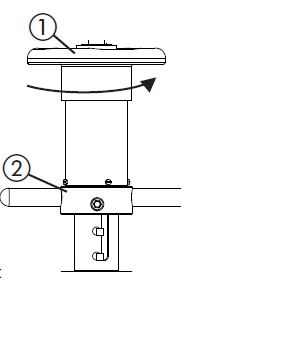

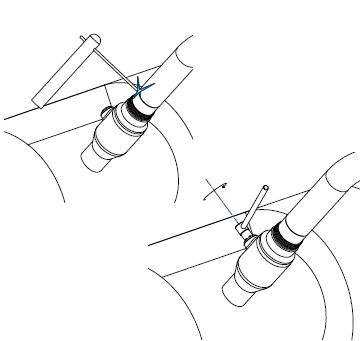

Kuye ngobude be-valve, i-shaft kufanele ilungiswe. Indlela enconyiwe yokuthola ubude be-shaft obufanele ikhonjiswe ezithombeni ezingezansi

- Ekuqaleni, phushela i-shaft phambili ukuze umshini wokushayela umshayeli uthinte ipayipi.

- Linganisa ubude phakathi kwehlombe eliphansi le-shaft nedivayisi engaphezulu.

- Ibanga elilinganisiwe kufanele libe phakathi kuka-100 - 170 mm.

- Lungisa ubude be-shaft uma kunesidingo.

- Ibanga lokudla linconywa ukuthi okungenani libe ngu-35 mm

Iziyalezo Zokusebenza

Amalungiselelo Egatsha ngaphambi kokuThepha Okushisayo

Ngaphambi kokuthi inqubo yokumba iqale, igatsha lobukhulu obunqunyiwe kufanele lilungiswe. Khumbula ukuthi usayizi wegatsha kufanele okungenani ube usayizi owodwa omncane omncane kunomugqa oyinhloko.

Ukususa i-insulation

Uma umugqa oyinhloko ufakwe i-insulated, susa i-insulation futhi uhlanze indawo yepayipi. Susa i-insulation kude ngokwanele ukuze ube nesikhala esanele sokushisela. Ibanga lokudla linconywa ukuthi okungenani libe ngu-35 mm.

Uma umugqa oyinhloko ufakwe i-insulated, susa i-insulation futhi uhlanze indawo yepayipi. Susa i-insulation kude ngokwanele ukuze ube nesikhala esanele sokushisela. Ibanga lokudla linconywa ukuthi okungenani libe ngu-35 mm.

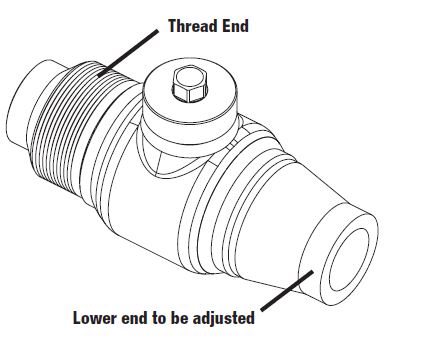

Ukulungisa i-Hot Tap Valve

Lungisa isiphetho esiphansi se-Danfoss Hot Tap Valve ibe yindilinga yomugqa oyinhloko usebenzisa umshini wokugaya. Kubalulekile ukuthi i-valve iphathwe ngendlela efanele ukuvimbela ukugaya noma ezinye izinhlayiya zangaphandle ukuthi zingene ku-valve. Kuphakanyiswa ukuthi ufake i-rag ukuvimbela ukulimala kwezingxenye zangaphakathi. Ngaphambi kwe-welding, i-rag kufanele isuswe. I-valve kufanele ivuleke ngokugcwele ngesikhathi sokulungiswa.

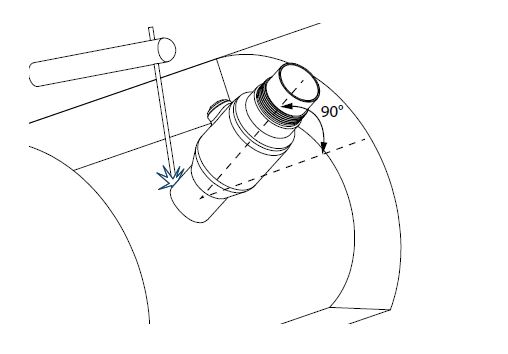

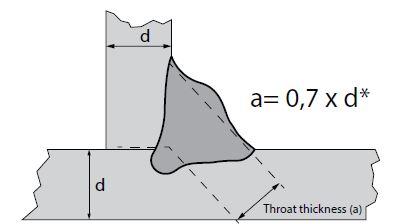

Ukushiselwa kwe-Hot Tap Valve kuya ku-Main Line

I-valve kampompi eshisayo ingashiselwa epayipini kuzo zonke izindawo lapho kungenzeka khona, kodwa i-engeli phakathi komugqa omaphakathi wepayipi elikhulu kanye ne-axis ye-valve kufanele ibe ngu-90 °. I-valve kufanele ishiselwe nge-welder eqinisekisiwe. Ubuchwepheshe bokushisela i-arc welding kagesi noma i-TIG welding, enamanje aphansi ngangokunokwenzeka. Qinisekisa ukuthi indawo eseduze komugqa ohlangene ayinawo ama-oxide futhi

amafutha. Qinisekisa ukuthi akukho mpahla yokushisela engena ku-valve. I-valve idinga ukushiselwa epayipini elikhulu ngokusebenza okukodwa okuvaliwe kwe-fillet weld. Gwema ukushisela kwe-run fillet ukuze uvimbele ukushisa ngokweqile kanye nemifantu ye-weld engase ibe khona. Kufanele kubhekwe ubudlelwano obuhle phakathi kokuqina komphimbo wokushisela kanye nogqinsi lwezindonga zazo zombili izingxenye zokushisela.

Ngaphambi kwe-welding, hlola indlela yokuvala ye-valve. Ngesikhathi sokushisela i-valve yebhola kumele ivuleke. I-valve kufanele ishiselwe nge-arc welding kagesi. Qinisekisa ukuthi azikho izinhlayiya ezingena ku-valve.

ISEXWAYISO

Gwema ukushuba kokuphela kwe-fillet welding elding amaningi ukuze uvimbele ukushisa ngokweqile.

Ukuhlanganiswa Kwedivayisi Yokubhoboza

Umshini wokuthepha we-Danfoss Hot ulethwa ngebhokisi, okuhlanganisa zonke izinto kanye namathuluzi engeziwe okuhlola ukuqaqa nokucindezela.

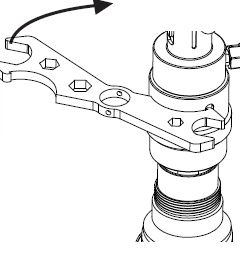

Ukuhlanganiswa kwe-Shaft yamasaha embobo> 32mm

Kuzokhethwa imbobo efanelekile engu-3 yobukhulu ngokwesahluko 3.3. Izoxhunywa ngokusonteka ngokuhamba kwewashi ku-drill chuck 4. Uma ixhunyiwe, izokhishwa kakhulu kangangokuthi izikhonkwane zokujika eziseduze zingaphushwa ezimbotsheni F ezansi kwesaha lembobo. I-drill chip magnet 2 ingabekwa eduze kwe-pilot drill 1 i-drill iphushelwe embobeni ye-chuck eqondanisa i-groove B kanye nesikulufu A. Ekugcineni, i-drill ikhiywa ngokuqinisa isikulufu A. I-drill chuck izoxhunywa phezulu kwe-drilling shaft 5 noma, uma isetshenzisiwe, isandiso se-shaft 7. Uma i-valve kufanele ibe yinde kangangokuthi ubude be-shaft bungeke bube bude ngokwanele ukuze kukwazi ukubhola, ubude be-shaft obusebenzisekayo bunganwetshwa ngokunwetshwa kokuphakelayo. isokhethi 6 ekugcineni ot shaft noma ngokungeza ama-shaftextensions 7 ekugcineni okuphansi kwe-drilling shaft 5.

Kuzokhethwa imbobo efanelekile engu-3 yobukhulu ngokwesahluko 3.3. Izoxhunywa ngokusonteka ngokuhamba kwewashi ku-drill chuck 4. Uma ixhunyiwe, izokhishwa kakhulu kangangokuthi izikhonkwane zokujika eziseduze zingaphushwa ezimbotsheni F ezansi kwesaha lembobo. I-drill chip magnet 2 ingabekwa eduze kwe-pilot drill 1 i-drill iphushelwe embobeni ye-chuck eqondanisa i-groove B kanye nesikulufu A. Ekugcineni, i-drill ikhiywa ngokuqinisa isikulufu A. I-drill chuck izoxhunywa phezulu kwe-drilling shaft 5 noma, uma isetshenzisiwe, isandiso se-shaft 7. Uma i-valve kufanele ibe yinde kangangokuthi ubude be-shaft bungeke bube bude ngokwanele ukuze kukwazi ukubhola, ubude be-shaft obusebenzisekayo bunganwetshwa ngokunwetshwa kokuphakelayo. isokhethi 6 ekugcineni ot shaft noma ngokungeza ama-shaftextensions 7 ekugcineni okuphansi kwe-drilling shaft 5.

ISEXWAYISO

Qinisekisa ukuthi i-drilling shaft ifakwe ngaphakathi ngokuphelele ukuze i-chuck pin 8 ihlanganiswe ne-chuck bottom.

ISAZISO

Hlola ukuthi i-pilot drill ayinkulu kakhulu futhi ayincane kakhulu kumasaha embobo esetshenzisiwe. Ukushayela okude kakhulu kokuhlola kwandisa ibanga lokudla ngokungadingekile kuyilapho ukubhola okufushane kakhulu kunganikezi.

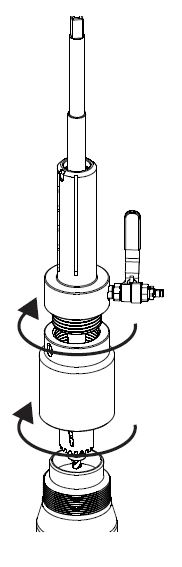

Ukuhlanganiswa kwe-shaft yamasaha embobo <32 mm

Ukuze uthole amasaha embobo <32mm kanye >24mm sebenzisa i-chuck encane engu-8. I-chuck encane 9 kufanele isetshenziselwe amasaha embobo <20mm. Khipha i-hole saw 3 kuya ku-chuck 8 noma 9 kuye ngosayizi wesaha wembobo. Umazibuthe 2 kufanele abekwe eduze kwe-drill yomshayeli 1 futhi aphushelwe emgodini we-chuck 8 noma 9. I-groove ku-drill yomshayeli 1 kufanele iqondaniswe nesikulufu G. Namathisela ukuhlanganisa ku-shaft 5. Sebenzisa i-shaft izandiso 7 noma isokhethi 6 uma kunesidingo.

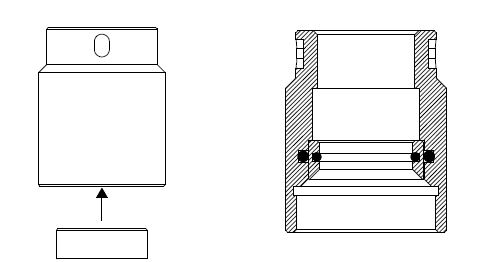

Umhlangano we-Danfoss JIP Adapter Socket

Ama-Danfoss JIP Hot Tapping Adapter alethwa ebhokisini lamathuluzi okuhlanganisa bonke osayizi ukusuka ku-DN 15/20 kuya ku-DN 100. Osayizi be-DN 25 kanye namasokhethi okunciphisa i-DN40 kufanele kwengezwe ku-adaptha yosayizi olandelayo.

Ukuhlanganiswa Kwedivayisi Kuvaluvu yokuthepha Okushisayo

I-adaptha kufanele ixhunywe kuntambo yevalvu ngokusonga ngesandla kuqala bese uyiqinisa ngesineke usebenzisa isikrufu. Ngenxa yokuthi i-O-ring eqinisayo, akudingekile ukusebenzisa amandla amaningi ngenkathi uxhuma izingxenye. Ngaphambi kokuxhuma i-adaptha kuvalvu, isaha sembobo emaphakathi efanele, i-chuck kanye ne-drill shaft kufanele kuhlanganiswe ndawonye lapho zonke izingxenye seziklwetshiwe, kuhlolwe ukuthi kusengenzeka yini ukuvala i-valve. Khipha umshini bese ulungisa futhi uma i-valve ingakwazi ukuvalwa.

Khumbula ukuvula NGOKUGCWELE i-valve ngemva kwalokho

Khumbula ukuvula NGOKUGCWELE i-valve ngemva kwalokho

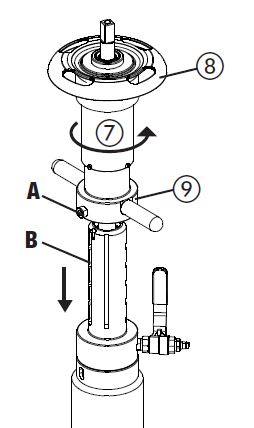

Ukufaka Iyunithi Yokuphakelayo

Idivayisi yokuphakelayo engu-7 isetshenziselwa ukwakha amandla okuphakelayo okumba. Intambo yokuphakelayo kufanele isongwe ukuze ibuyele emuva ngokuphelele ngokuphendula isondo lokuphakelayo ngo-8 ukuya kwewashi.

Isokhethi yokulungisa engu-9 izoxhunywa kuqala ngokuqondisa izisele nezikulufu zikagayidi A futhi lapho ngemva kokuslayida endaweni eseduze yokukhiya engu-B emzimbeni womshini. Ukususwa ngokweqile kususwa ngokuphendula isondo lokuphakelayo 8 ukuya kwewashi. Linganisa ibanga lokuphakelayo njengoba kuchazwe esahlukweni 3.3 futhi ulilungise nge-shaft noma izandiso zesiphakeli uma kungenzeka.

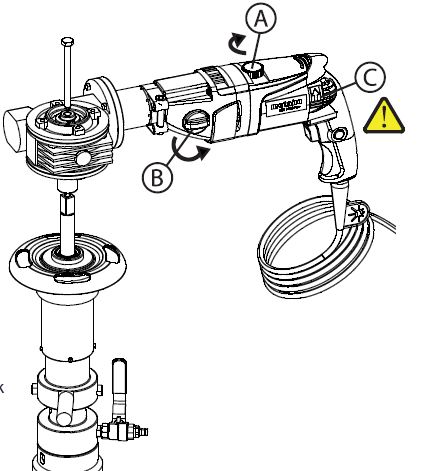

Ukufaka Iyunithi Yokushayela

Isikwele se-shaft kufanele siqondaniswe nembobo yesikwele sedrayivu bese sixhunywa futhi sikhiywe kusetshenziswa isikulufu sokuxhuma. Ijubane elijikelezayo elilungile likhethwa ukubhoboza ngokwethebula elingezansi. Ku-drill yomshayeli i-rpm ephezulu ifanelekile. Umcibisholo ohlangothini lwesobunxele lomshini obheke phezulu ubonisa isiqondiso esifanele sokuzungezisa ngokwewashi.

Isikwele se-shaft kufanele siqondaniswe nembobo yesikwele sedrayivu bese sixhunywa futhi sikhiywe kusetshenziswa isikulufu sokuxhuma. Ijubane elijikelezayo elilungile likhethwa ukubhoboza ngokwethebula elingezansi. Ku-drill yomshayeli i-rpm ephezulu ifanelekile. Umcibisholo ohlangothini lwesobunxele lomshini obheke phezulu ubonisa isiqondiso esifanele sokuzungezisa ngokwewashi.

Isexwayiso

Idrayivu akufanele neze ihambisane nokuhamba kwewashi njengoba intambo yokuxhuma i-drill shaft ingase ivuleke futhi i-drill chuck ingalahleka okubangele ingozi enkulu yokuvuza kwamanzi ashisayo kusukela ekuvulekeni kwe-shaft.

Ukujika Isivinini Sokubhoboza Kumapayipi Ensimbi

Izilungiselelo zomshini wokumba we-Metabo BE 1100 eziboniswe kuthebula elingezansi. Izivinini zokujika ezinconyiwe ezisuselwe kulwazi lwesikhathi eside lwabakhiqizi. Ekuqaleni kokusebenza kokumba futhi ekupheleni kokusebenza kokumba amandla okusika angahluka kakhulu ngakho umuntu kufanele alungele ukushintsha izilungiselelo.

| Usayizi wevalvu | Isivinini sokuguqula ukubhoboza umphini [rpm] | Isivinini sokuguqula kagesi shayela [rpm] | Ukusetha | Ukusetha |

| I-DN 15/20 | 115 | 1600 | 9 | 1 |

| I-DN 32/25 | 80 | 1100 | 9 | 1 |

| DN 50/40 | 80 | 1100 | 9 | 1 |

| I-DN 65 | 55 | 750 | 8 | 1 |

| I-DN 80 | 55 | 750 | 8 | 1 |

| I-DN 100 | 55 | 750 | 8 | 1 |

| I-Pilot Drill | 200 | 2800 | 9 | 2 |

Inqubo Yokucofa Okushisayo

Ngemuva kokuthi umshini usuhlanganisiwe, konke ukuxhumana kuzobhekwa futhi kulawulwe. Umsebenzisi angaqhubeka nezinyathelo ezilandelayo ngemva kwalokho.

Ukuhlolwa Kwengcindezi

Ngaphambi kwegatsha langempela ukuhlolwa kokucindezela kufanele kwenziwe ukuze kuqinisekiswe ukuqina kokubili kwe-welding seams ye-valve kanye nemishini yokumba.

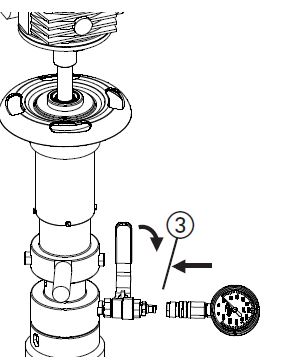

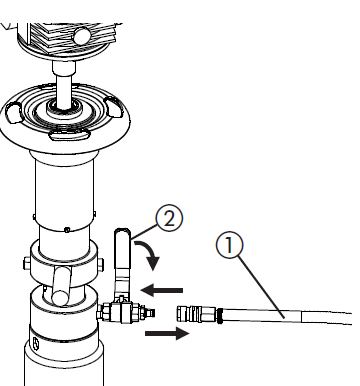

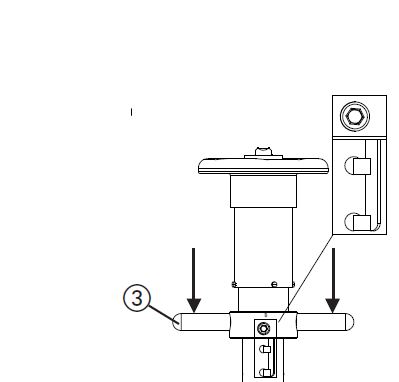

Ipayipi 1 lamanzi abandayo noma umoya onomfutho uxhunywe ku-coupler yomzimba. Iqhude lokulawula 2 liyavulwa ukuze kungene ingcindezi. Uma uthanda, vala iqhude 2 bese ufaka igeji yokucindezela engu-3 ukuze uqaphe ukwehla okungenzeka kwengcindezi. Ngemuva kokuhlolwa, uketshezi lokuhlola lukhishwa ngeqhude elifanayo lokulawula 2. Uma kwenzeka ukuvuza okwenzekayo, akuvunyelwe ukuqala inqubo yokubhoboza kuze kube yilapho ukwehluleka kuqedwa.

Ipayipi 1 lamanzi abandayo noma umoya onomfutho uxhunywe ku-coupler yomzimba. Iqhude lokulawula 2 liyavulwa ukuze kungene ingcindezi. Uma uthanda, vala iqhude 2 bese ufaka igeji yokucindezela engu-3 ukuze uqaphe ukwehla okungenzeka kwengcindezi. Ngemuva kokuhlolwa, uketshezi lokuhlola lukhishwa ngeqhude elifanayo lokulawula 2. Uma kwenzeka ukuvuza okwenzekayo, akuvunyelwe ukuqala inqubo yokubhoboza kuze kube yilapho ukwehluleka kuqedwa.

Ukuqala Inqubo Yokubhoboza

Inqubo yokumba iqala ngokwakha imbobo emaphakathi ne-pilot drill.I-rpm ephezulu ikhethwa kumaswishi futhi Okuphakelayo kuqalwa kancane ngokuphendula kancane kancane isondo lokuphakelayo libheke kwewashi. Yondla kancane kakhulu ekuqaleni ukuze uqiniseke ukuthi indawo yokubhoboza iphakathi nendawo. Ukungena kokubhoboza umshayeli odongeni lwamapayipi amakhulu kungabonwa ngokubheka imitha yokucindezela7. Ukuphakamisa inaliti kubonisa ukungena. Okuphakelayo okwanele kusetshenziswa ubuningi. i-rpm kufanele iqhutshekwe kuze kube yilapho i-drill yomshayeli ingena odongeni lomugqa omkhulu. Ngemuva kokuthi umshini wokubhoboza umshayeli usuphelile, ijubane lokujika lesaha lembobo kufanele lilungiswe. Qala ukuphakela ngembobo isaha ngokucophelela bese ugcine

isitendi esingashintshi. Ukuqapha okwengeziwe kufanele kukhonjiswe ukuze ubhekane namandla okusabela. Donsa umshini unxephezele amandla. Lapho ukumba kuqhubekela phambili, izinga lokudla lingasheshiswa kancane kuze kube sekupheleni kokubhoboza Ukungena kokugcina kodonga lwamapayipi amakhulu kungaqinisekiswa ngokuphusha i-shaft phambili ngokuqinile ngaphandle kokujika i-shaft. Lapho iqhubeka, imbobo kufanele ikhululeke.

ISEXWAYISO

ISEXWAYISO

Idrayivu akumele ikhiyelwe ekusebenzeni okuqhubekayo, njengoba ukuhlukahluka kwamandla omshini kungase kubangele ukulahleka kokulawula kwedrayivu okungalindelekile futhi ngaleyo ndlela kubangele

umonakalo omkhulu ku-opharetha. Qaphela amandla okusabela avela ekusikeni.

ISEXWAYISO

Idrayivu kanye ne-shaft kumele zihlale zijike ISE-CLOCKWISE. Ukuvuleka ngengozi kwemicu yokuxhuma ye-shaft kungase kubangele umonakalo omkhulu ku-opharetha. UNGALOKOTHI usebenzise amathuluzi e-lever esondweni lokuphakela futhi wondle ngokucophelela kakhulu. Lapho isaha lembobo libhajwa, yeka ukufunza noma ujikise isaha kancane emuva. Eqhubeka edla kancane.

Ukulungisa Okuphakelayo

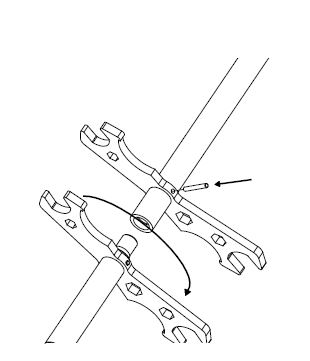

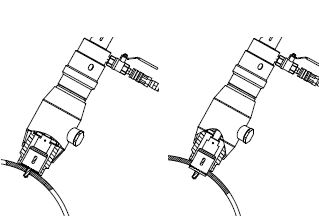

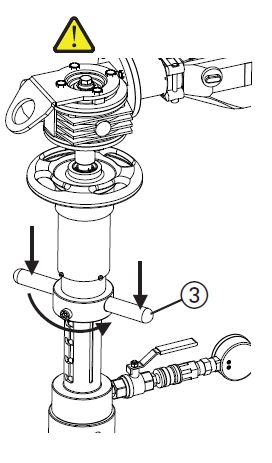

Uma izinga lokuphakelayo liphela futhi isondo lokuphakelayo elingu-1 lingasakwazi ukuphendulwa, isokhethi 2 yokulungisa kufanele ikhishwe futhi ikhiyelwe endaweni ephansi. Uma ingcindezi ingu>12 bar, sebenzisa i-chain block kulo msebenzi. Okokuqala, shintsha iyunithi yokushayela. Skrola isondo lokuphakelayo 1 isibali ngokwewashi. Ungayisusi kakhulu njengoba ihuku le-pilot drill lingase liphuke.

Bamba izibambo zokulungisa 3 bese uziphushela phambili ngokuqinile.Jikisa isokhethi yokulungisa 2 ize ikhishwe. Phusha isokhethi yokulungisa phansi ibheke emseleni olandelayo. Qhubeka uphendulela isondo lokuphakelayo 1 isibali ngokwewashi kuze kube yilapho kufinyelelwa khona umsele olandelayo. Khiya isokhethi 2 yokulungisa emseleni olandelayo ngokuyijika njengewashi.

Bamba izibambo zokulungisa 3 bese uziphushela phambili ngokuqinile.Jikisa isokhethi yokulungisa 2 ize ikhishwe. Phusha isokhethi yokulungisa phansi ibheke emseleni olandelayo. Qhubeka uphendulela isondo lokuphakelayo 1 isibali ngokwewashi kuze kube yilapho kufinyelelwa khona umsele olandelayo. Khiya isokhethi 2 yokulungisa emseleni olandelayo ngokuyijika njengewashi.

Isexwayiso

Uma ungaqiniseki mayelana namandla asebenza ku-shaft ngenkathi uyikhulula, sebenzisa i-chain block kulo msebenzi. Kusuka kokuhlangenwe nakho kwabakhiqizi, kuhle ukuyisebenzisa ngokucindezela> 12 bar.

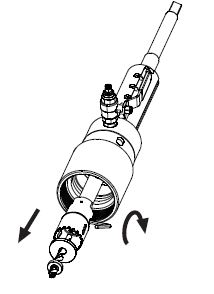

Ikhulula Iyunithi Yokuphakelayo

Ngemva kokuqeda ukumba, idrayivu izokhishwa phezulu komhlangano. Ezingcindezini eziphansi, lokhu kungenziwa ngesandla. Ngezingcindezi eziphakeme> 12 bar kunconywa kakhulu ukusebenzisa i-chain block. Zombili izibambo ezilungisayo 3 zizobanjwa, ziphushelwe phambili futhi ngesikhathi esifanayo ziphendulwe ngokuphambene newashi ukuze kukhululwe isokhethi ye-adusting Isokhethi manje ingahlehliswa ngokuslayida izikulufu zamandla zisuke ngokuphelele emzimbeni wokubhoboza. Khipha i-shaft ngokuphelele. I-chuck ngaphakathi kokubhoboza

Igumbi livimba umgodi ukuthi ungaphumi.

Isexwayiso

Uma ungaqiniseki mayelana namandla asebenza ku-shaft ngenkathi uyikhulula, sebenzisa i-chain block kulo msebenzi. Kusukela kokuhlangenwe nakho kwabakhiqizi, kuyancomeka ukuthi uyisebenzise ku-a

ingcindezi> 12 bar.

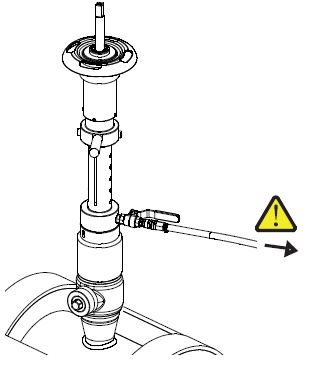

Ukuvala I-Valve Nokukhulula Ingcindezi

I-valve kufanele ivalwe ngokuphelele ngokuphendula ibhola usebenzisa ukhiye we-allen ofanele futhi uyiphendule amadigri angu-90 njengoba ibhola eliku-valve kampompi oshisayo lingenaso isitobhi esizenzakalelayo, kungase kudingeke ulungise indawo yebhola kuze kube yilapho ivaleke kahle. . Ukuqina kungalawulwa ngokuvula iqhude lokulawula. Xhuma ipayipi ku-cock yokulawula bese uyivula ukuze ukhulule ukucindezela.

ISEXWAYISO

ISEXWAYISO

Gcina ibanga elanele ku-hose ngenkathi ukhulula ukucindezela ukuze uzivikele. Qinisekisa ukuthi i-valve ivalwe ngokuphelele.

Ukuqaqa Umshini

Umshini uhlakazwa ngendlela ephambene. Ekugcineni, ucezu olusikiwe luzosuswa. I-pilot drill ixegiswa ngokuvula isikulufu sokugcina kusetshenziswa ukhiye ofanele we-allen. I-drill ephakathi iyakhishwa futhi isigqebhezana ngisisuse eduze kwesiqu sokubhoboza. Ama-drill chips ahlanzwa kumagnethi wokuqoqa.

Ukudala Igatsha Elisha

Ekudaleni igatsha elisha, landela ngokucophelela imiyalelo yabakhiqizi bamavalvu. Lapho i-Hot Tapping isifeziwe, ulayini omusha ungaxhunywa ku-valve kampompi eshisayo ye-Danfoss ngokushisela i-arc kagesi. Phakathi nalokho kusebenza, qiniseka ukuthi ama-sealings ngaphakathi kwe-valve awashisi ngokweqile. Ngemva Welding futhi lapho umugqa uvunyiwe

qala ukusebenza, vula i-valve kuqala kancane kakhulu. Vula i-valve NGOKUPHELELE ngemva kwalokho. Ngemuva kokuthi i-valve ivuleke ngokuphelele, screw ipulaki ephezulu. Kunconywa ukushisela ipulaki entanyeni ye-valve ngokugijima okukodwa okuvaliwe kwe-fillet weld. Gcwalisa igebe phakathi kwepulaki ephezulu nentamo yevalvu ngokuphelele. Gwema i-run fillet welding ukuze uvimbele ukushisa ngokweqile.

Uhlelo Lokunakekela kanye Nohlu Lwezingxenye Ezisele

Ngaphambi nangemva kokuthepha okushisayo, yonke idivayisi kufanele ihlolwe futhi inakekelwe. Ungawuqali umsebenzi wokumba ngaphandle kokuhlola idivayisi ngaphambilini. Ungalokothi uqale ukubhola uma kukhona umonakalo obonakalayo. Uma kuvela izinkinga zobuchwepheshe ungangabazi ukuxhumana nomkhiqizi u-Danfoss. Izingxenye ezilandelayo kufanele zihlolwe mayelana nesimo sazo ngaphambi kokubhobozwa kwazo zonke

| I-Central Drill | Hlola i-central drill mayelana nekhono layo lokusika .Shintsha i-drill uma kudingeka. |

| Ukubekwa uphawu | Hlanza ama-sealings futhi uwahlole mayelana nomonakalo. Zishintshe uma kunesidingo. Wagcobe nge-sealant ngaphambi kokusebenzisa idivayisi. |

| I-Hole Saw | Hlola imbobo isaha mayelana nekhono layo lokusika .Shintsha isaha lembobo uma kunesidingo. |

| Umphini | Hlola i-shaft mayelana nokulimala kwendawo. Hlola izintambo zokuxhuma. Gcina shaft ngendlela efanele futhi ugweme ukuyiwisa. |

| Amabhere | Hlola okubukwayo isimo sendawo engaphakathi yokuthwala |

| Umucu wesondo lokuphakelayo | Hlola ukuthi isondo lokuphakelayo lihamba kahle yini. |

| Idivayisi Yonke | Hlanza ucingo ngemva kokusetshenziswa ngakunye futhi uluhlole mayelana nokulimala okubukwayo |

Uma kwenzeka umonakalo omkhulu wocingo ubonakala, sicela uxhumane nomkhiqizi we-Danfoss.

IZINGXENYEVIEW

| Isikhundla | Ingxenye |

| 1 | Imoto kagesi |

| 2 | Isokhethi yesandiso sokuphakelayo |

| 3 | Indandatho yokubopha 43 mm |

| 4 | I-chock eyinhloko |

| 5 | Ukuhlanganisa |

| 6 | I-coupling casing |

| 7 | Indandatho ebambayo |

| 8 | I-Gear fastening Screw |

| 9 | Isikulufu sokuxhuma i-M6 |

| 10 | Ipuleti lokuxhuma i-Shaft brake |

| 11 | Isikulufu sokuxhuma i-M5 |

| 12 | Igiya lezikelemu 7:1 |

| 13 | I-chock yesibili |

| 14 | I-shaft yesibili |

| 15 | Ukuvala Izindebe |

| 16 | I-Trust Bearing |

| 17 | Okuphakelayo Socket |

| 18 | I-Retainer Screw |

| 19 | Isibambo |

| 20 | Ukulungisa Isokhethi |

| 21 | Isikulufu Samandla |

| 22 | I-Ball Point Screw |

| 23 | Indandatho Yokugcina Ephethe Okungaphezulu |

| 24 | Ukubekwa uphawu Okungaphezulu |

| 25 | I-O-ring engaphezulu |

| 26 | I-PTFE-Bearing ephezulu |

| 27 | Ukuvalwa kwe-Shaft |

| 28 | Umzimba |

| 29 | I-PTFE Ephansi |

| 30 | Ukuvalwa Komzimba |

| 31 | Indandatho Yokugcina Engaphansi |

| 32 | I-Double Nipple |

| 33 | Lawula Iqhude |

| 34 | Isixhumi Esisheshayo wesilisa |

| 35 | Isixhumi Esisheshayo sowesifazane |

| 36 | Isokhethi 1/4 |

| 37 | Ibha ye-Manometer 40 |

| 38 | I-Central Drill evamile |

| 39 | I-Central Drill ifushane |

| 40 | Isandiso se-Shaft DN20 |

| 41 | Chuck evamile |

| 42 | Chuck encane |

| 43 | Ukwandiswa kwe-Shaft 90 mm |

| 44 | I-Base shaft |

| 45 | Ukwandiswa kwe-Shaft 180 mm |

| 46 | I-Chain Block |

| 47 | I-TONISCO Special Wrench |

| 48 | Iphinikhodi yokuvula |

| 49 | I-Allen Key 3 mm |

| 50 | I-Allen Key 4 mm |

| 51 | I-Allen Key 5 mm |

| 52 | Umazibuthe |

Ukusebenzisa i-Chain Block

Ukuze uthole ukucindezela okuphezulu > ibha engu-12 kunconywa kakhulu ukusebenzisa i-chain block ukulungisa isifunzo noma ukukhululwa okuphephile kweyunithi yokuphakelayo. Okokuqala, lenga ingxenye engaphezulu yehhuku kupuleti lokuxhuma 1. Enye ihhuku kufanele ibe igxunyekwe endaweni ezinzile ohlangothini lokusebenza isb. eduze kwepayipi elikhulu. Lungisa iswishi ibe yindawo emaphakathi mahhala

ukunyakaza kweketango. Qinisa iketango ngokuqala ngokudonsa elinye icala leketango futhi ngemva kwalokho ngokujikisa isondo ngokwewashi. Lungisa ukushintshela kusimo se-UP

Phusha phansi isokhethi 3 ngokuhambisa i-lever emuva naphambili. Ngaphambi kokukhulula isikulufu sokukhiya esikhaleni esokhethi 3 sokulungisa lungisa iswishi ibe yindawo ephansi uma ufuna ukukhulula iyunithi yokuphakelayo. Uma ufuna ukulungisa okuphakelayo, shiya iswishi endaweni ephezulu. Vula isokhethi yokulungisa 3 ngokuphambene newashi ukuze umise kabusha i-shaft noma ulungise okuphakelayo.

ISEXWAYISO

Qaphela ukuthi ungasiminyi isandla sakho kuketango.

ISEXWAYISO

Ungashintshi iswishi iye endaweni emaphakathi lapho iketango lingaphansi kokuxineka.

Izinanyathiselwa A1

Imiyalelo Yezokuphepha Mayelana Nophiko Lokushayela Kagesi

Isexwayiso

Uma usebenzisa amathuluzi kagesi, izinyathelo zokuphepha eziyisisekelo kufanele zihlale zilandelwa ukuze kuncishiswe ingozi yokushaqeka kagesi, ukulimala komuntu siqu kanye nomlilo, kuhlanganise nalokhu okulandelayo:

- Gcina indawo yokusebenza ihlanzekile.

- Izindawo eziminyene namabhentshi kumema ukulimala.

- Cabangela indawo yokusebenza.

- Ungawavezi ama-toll kagesi emvuleni. Ungasebenzisi amatoll kagesi ku-damp noma izindawo ezimanzi.

- Gcina indawo yokusebenza ikhanya kahle.

- Ungasebenzisi amathuluzi kagesi uma kukhona uketshezi oluvuthayo noma amagesi.

- Zivikele ekushayweni kukagesi.

- Uma usebenza ngamathuluzi kagesi, gwema ukuthintana komzimba nezingxenye ezinobumba isib. Amapayipi, ama-radiator, iziqandisi, iziqandisi.

- Uma usebenzisa ama-cooler conductive kagesi noma izinto zokugcoba noma uma kunezimo ezimbi kakhulu ongazisebenzisa isb. Izinga eliphezulu lomswakamo, ukuthuthukiswa noma uthuli lwensimbi, njll.) Lapho usebenza ngamathuluzi kagesi, sebenzisa ( FI, DI, PRDC ) isivikelo samanje esisele. amadivayisi kunoma iyiphi indawo yokukhipha amandla.

- Gcina izingane kude.

- Ungavumeli izibukeli ithuluzi lokuxhumana noma amandla lead. Bonke ababukele kufanele bagcinwe kude nendawo yokusebenza.

- Gcina ithuluzi lamandla angasebenzi lomsebenzi. Lapho ingasetshenziswa gcina amathuluzi endaweni eyomile, kungaba ilokha phezulu noma phezulu, endaweni lapho izingane zingafinyeleleki khona.

- Ungalokothi uphoqe ithuluzi lamandla. Izokwenza umsebenzi kangcono futhi iphephe ngezinga obunakekelwa ngalo.

- Sebenzisa amathuluzi amandla alungile emsebenzini.

- Ungaphoqi amathuluzi anamandla amancane ukwenza umsebenzi wethuluzi elisindayo.

- Ungasebenzisi amathuluzi kagesi ngenjongo engahlosiwe.

- Ungalinge ukwenzele example , sebenzisa isaha esiyindilinga ukusika izitho zesihlahla noma izingodo.

- Gqoka ngendlela efanele.

- Ungagqoki izingubo ezixegayo noma ubucwebe.

- Angabanjwa ezingxenyeni ezihambayo.

- I-Rubber glover nezicathulo ezingashiyizi ziyanconywa uma usebenza ngaphandle.

- Gqoka isembozo esivikela izinwele ukuze uqukathe ukuzwa okude.

- Gqoka izibuko zokuphepha kanye nemaski yobuso noma imaski yothuli uma umsebenzi unothuli.

- Ungasebenzisi kabi umthofu. Ungalokothi uphathe ithuluzi lamandla ngomthofu noma nge-yank lead ukuze unqamule ithuluzi esitsheni.

- Gcina umthofu kude nokushisa, uwoyela namaphethelo acijile Vikela ucezu lomsebenzi.

- Sebenzisa i-clamps noma i-vice yokubamba ucezu lomsebenzi. Kuphephile kunokusebenzisa isandla sakho futhi kukhulula izandla zombili ukuthi zisebenze.

- Ungeqisi. Gcina izinyawo ezifanele futhi ulinganise ngaso sonke isikhathi.

- Gcina amathuluzi ngokucophelela.

- Gcina amathuluzi ebukhali futhi ehlanzekile ukuze uthole ukusebenza okungcono nokuphephile.

- Landela imiyalelo yokusevisa amathuluzi okushintsha.

- Hlola imikhondo yamathuluzi kagesi ngezikhathi ezithile futhi uma yonakalisiwe, yilungise ngendawo yesevisi egunyaziwe. Hlola imikhondo yesandiso ngezikhathi ezithile bese uyishintsha uma yonakele.

- Gcina izibambo zomile, zihlanzekile futhi zingenawo uwoyela namafutha.

- Nqamula amathuluzi kagesi, lapho engasebenzi, ngaphambi kokuseviswa nalapho ulungisa izisekeli ezifana nama-blade, izingcezu nezisiki.

- Susa okhiye nezipanela. Yenza umkhuba wokuhlola ukuze ubone ukuthi okhiye namathuluzi okulungisa ayasuswa ethuluzini lamandla ngaphambi kokuwavula.

- Gwema ukuqala ungahlosile.

- Ungaphathi ithuluzi lamandla elixhunyiwe elinomunwe ocingweni. Qiniseka ukuthi iswishi ivaliwe lapho uxhuma.

- Imikhondo yokwandisa ukusetshenziswa kwangaphandle. Uma amathuluzi kagesi esetshenziswa ngaphandle, sebenzisa kuphela umthofu wokunweba ohloselwe ukusetshenziswa ngaphandle futhi umakwe kanjalo.

- Hlala uqaphile.

- Qaphela ukuthi wenzani.

- Sebenzisa ingqondo.

- Ungasebenzisi ithuluzi lamandla uma ukhathele.

- Hlola ithuluzi lamandla ukuze uthole izingxenye ezilimele. Ngaphambi kokusetshenziswa okuqhubekayo kwethuluzi lamandla, unogada noma enye ingxenye eyonakele kufanele ibhekwe ngokucophelela ukuze kutholakale ukuthi izosebenza kahle futhi yenze umsebenzi wayo ohlosiwe.

- Hlola ukuqondanisa kwezingxenye ezihambayo, izingxenye ezibophayo noma ezihambayo, ukuphuka kwezingxenye, ukukhwezwa, kanye nanoma yisiphi esinye isimo esingase sithinte ukusebenza kwethuluzi lamandla.

- Unogada noma enye ingxenye eyonakele kufanele ilungiswe kahle noma ifakwe indawo yesevisi egunyaziwe ngaphandle kwalapho kuboniswe ngenye indlela emiyalweni yokusebenza.

- Iba namaswishi angalungile athathelwe indawo indawo yesevisi egunyaziwe. Ungalisebenzisi ithuluzi lamandla uma iswishi ingayivuli futhi ingayivali.

Isexwayiso

Ukuze uphephe, sebenzisa kuphela izesekeli nezinamathiselo ezichazwe emiyalweni yokusebenza noma ezihlinzekwe noma ezituswe umkhiqizi wamathuluzi. Ukusetshenziswa kwamathuluzi ngaphandle kwalawo achazwe emiyalweni yokusebenza noma kukhathalogi yokufakwa kwamathuluzi anconyiwe noma izesekeli kungaholela engcupheni yokulimala komuntu siqu. Yenza ukuthi ithuluzi lakho lamandla lilungiswe yisikhungo sesevisi esigunyaziwe. Ukulungisa kufanele kwenziwe kuphela yisikhungo sesevisi esigunyaziwe.

Amadokhumenti / Izinsiza

|

danfoss Ibhokisi lamathuluzi le-JIP-Hot Tapping Machine [pdf] Imaniwali yosebenzisayo I-JIP-Hot Tapping Machine Ibhokisi Lamathuluzi, Ibhokisi Lamathuluzi Lomshini Wokucofa, Ibhokisi Lamathuluzi Lomshini |