I-Danfoss EKC 202A Isilawuli Sokulawula Izinga lokushisa

Isingeniso

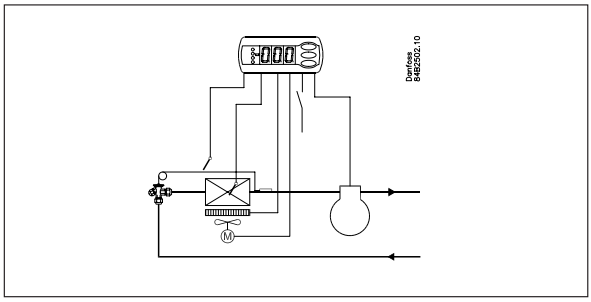

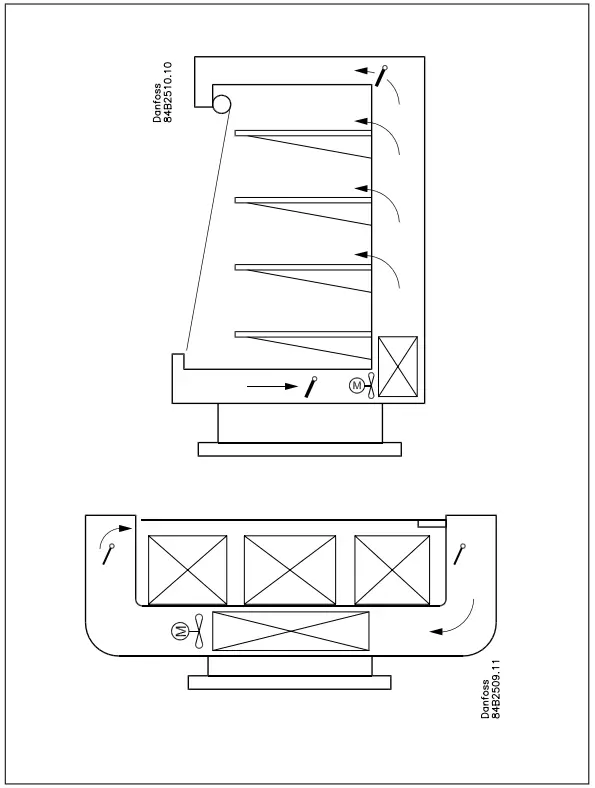

Isicelo

- Isilawuli sisetshenziselwa ukulawula izinga lokushisa lezinto ezisebenza esiqandisini namagumbi abandayo ezitolo ezinkulu

- Ukulawulwa kwe-defrost, abalandeli, i-alamu nokukhanya

Isimiso

Isilawuli siqukethe isilawuli sezinga lokushisa lapho isignali ingatholwa kusuka kunzwa eyodwa yezinga lokushisa. Inzwa ifakwa ekugelezeni komoya obandayo ngemva kwe-evaporator noma ekugelezeni komoya ofudumele ngaphambi nje kwe-evaporator. Isilawuli silawula ukuncibilika kweqhwa nge-natural defrost noma i-electric defrost. Ukusika okuvuselelwe ngemuva kokumiswa kweqhwa kungafezwa ngokusekelwe esikhathini noma izinga lokushisa. Isilinganiso sezinga lokushisa le-defrost singatholakala ngokuqondile ngokusebenzisa inzwa ye-defrost. Ukudluliselwa okubili kuya kwezine kuzosika imisebenzi edingekayo ngaphakathi nangaphandle - isicelo sinquma ukuthi:

- Isiqandisi (i-compressor noma i-solenoid valve)

- I-Defrost

- Umlandeli

- I-alamu

- Ukukhanya

Izinhlelo zokusebenza ezahlukene zichazwe ekhasini elilandelayo.

I-Advantages

- Imisebenzi ehlanganisiwe yesiqandisi-zobuchwepheshe

- Nciphisa uma kudingeka kumasistimu angu-1:1

- Izinkinobho nophawu kushumekwe ngaphambili

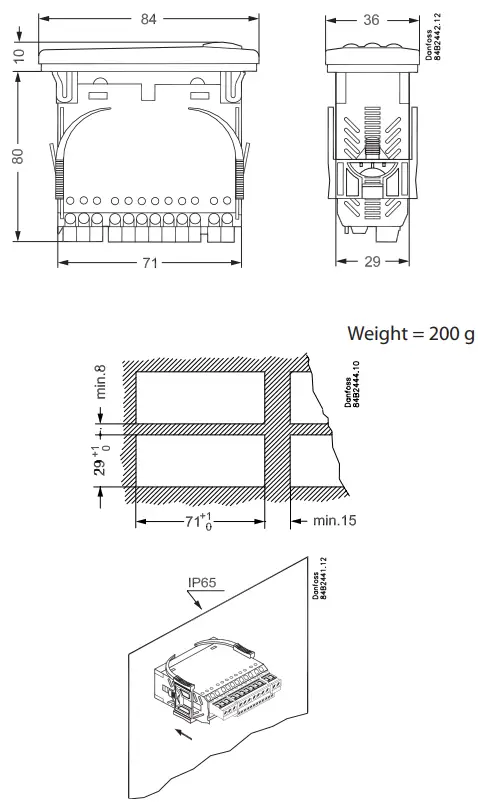

- IP65 ebiyelwe kuphaneli yangaphambili

- Okokufaka kwedijithali kokunye:

- Umsebenzi wokuxhumana nomnyango nge-alamu

- Ukuqala kwe-Defrost

- Ukuqala/ukumisa ukulawulwa

- Ukusebenza ebusuku

- Ukushintsha phakathi kwezithenjwa zezinga lokushisa ezimbili

- Umsebenzi wokuhlanza ikesi

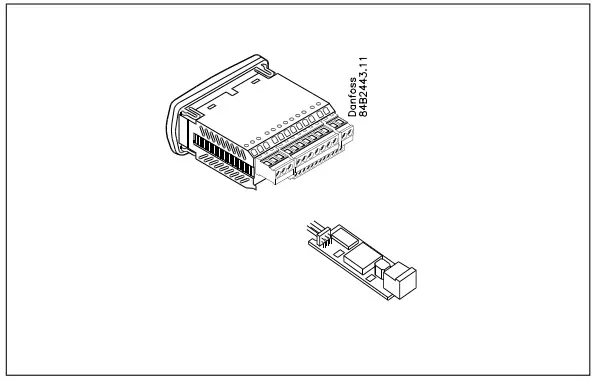

- Uhlelo olusheshayo ngokhiye wokuhlela

- Ukulinganisa Kwefekthri ye-HACCP okuzoqinisekisa ukunemba okungcono kokulinganisa kunalokho okushiwo ku-EN ISO 23953-2 ejwayelekile ngaphandle kokulinganisa okulandelayo (inzwa ye-Pt 1000 ohm)

Imojula eyengeziwe

- Ngemva kwalokho isilawuli singafakwa imojuli yokufaka uma uhlelo lokusebenza luyidinga. Isilawuli silungiswe ngepulaki, ngakho-ke imojula kufanele iphushwe nje.

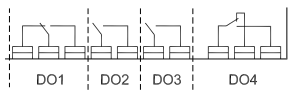

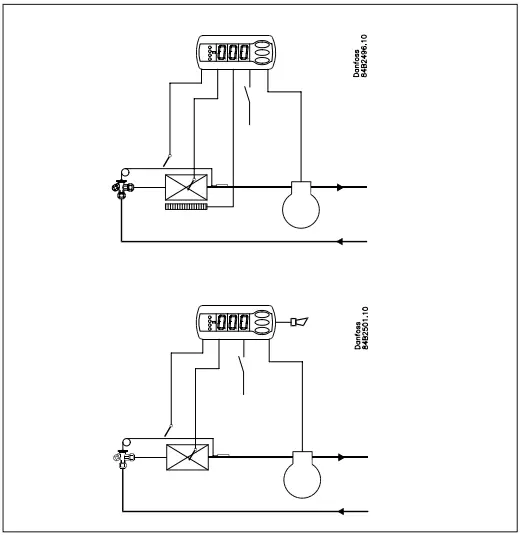

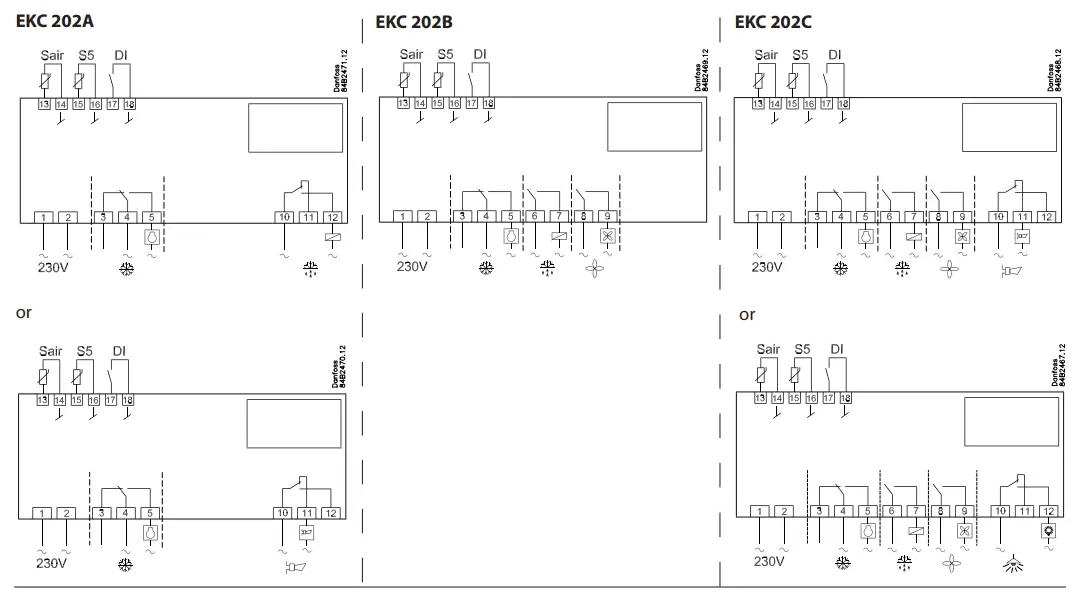

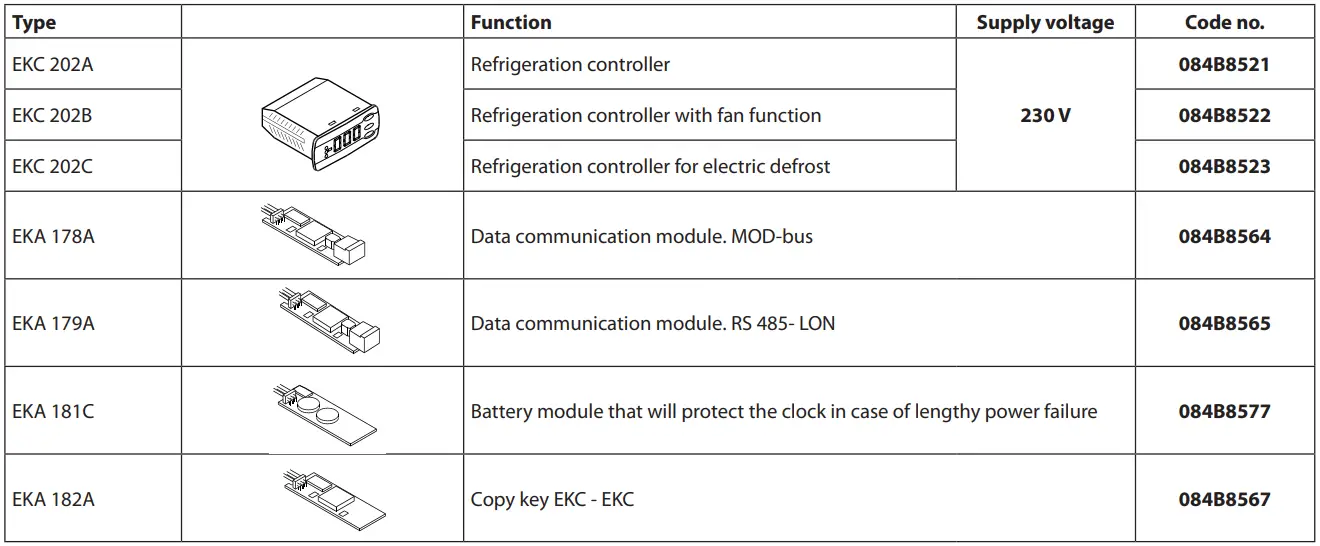

I-EKC 202A

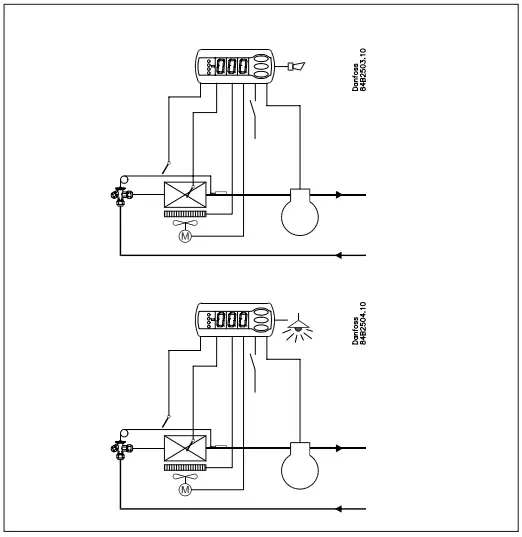

Isilawuli esinemiphumela emibili edluliswayo, izinzwa ezimbili zokushisa, nokokufaka kwedijithali. Ukulawula izinga lokushisa ekuqaleni/ukuma kwe-compressor/solenoid valve

Inzwa ye-Defrost

I-defrost kagesi / i-gas defrost

Umsebenzi we-alamu

Uma i-alamu idingeka, inombolo ye-relay yesibili ingase isetshenziselwe yona. I-Defrost yenziwa lapha ngokusakazwa komoya njengoba abalandeli besebenza ngokuqhubekayo.

I-EKC 202B

Isilawuli esinemiphumela emithathu edluliswayo, izinzwa zokushisa ezimbili, nokokufaka kwedijithali. Ukulawula izinga lokushisa ekuqaleni/ukuma kwe-valve ye-compressor/solenoid, inzwa ye-Defrost, I-electric defrost / i-gas defrost Relay okukhipha 3 isetshenziselwa ukulawula fan.

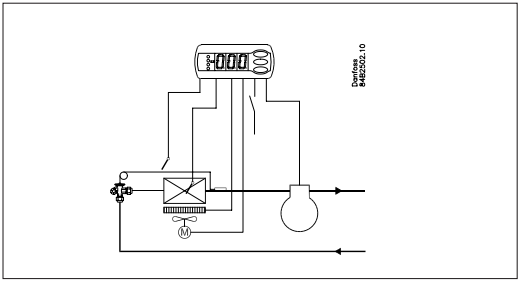

I-EKC 202C

Isilawuli esinemiphumela edluliselwe emine, izinzwa zokushisa ezimbili, nokokufaka kwedijithali. Ukulawula izinga lokushisa ekuqaleni/ukuma kwe-compressor/solenoid valve, ama-Defrost sens, noma i-electric defrost/i-gas defrost. Ukulawulwa kokuphuma kwe-Fan Relay 4 kungasetshenziselwa umsebenzi we-alamu noma umsebenzi wokukhanya.

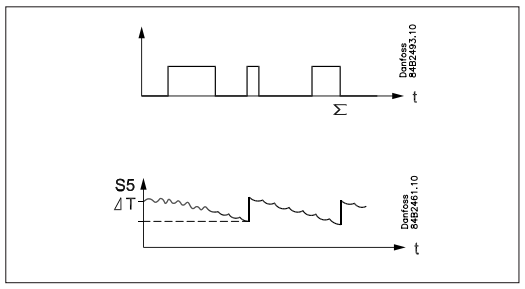

Ukuqala kwe-defrost

I-defrost ingaqalwa ngezindlela ezahlukene

Isikhawu: I-Defrost iqalwa ngezikhathi ezimisiwe, ake sithi, njalo emahoreni ayisishiyagalombili

- Isikhathi sesiqandisi: I-Defrost iqalwa ngezikhathi ezithile zesiqandisi. Ngamanye amazwi, isidingo esiphansi sesiqandisi "sizokuhlehlisa" ukuchithwa kweqhwa okuzayo

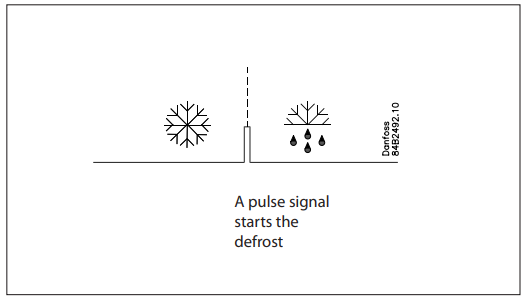

- Oxhumana naye I-Defrost iqalwa lapha ngesignali ye-pulse kokokufaka kwedijithali.

- Incwadi yezandla: I-defrost eyengeziwe ingenziwa isebenze kusukela enkinobho ephansi yesilawuli

- I-S5-Temp. Kuzinhlelo ze-1:1, ukusebenza kahle kwe-evaporator kungalandelwa. Ukufaka iqhwa kuzoqala ukuncibilika.

- Isheduli I-Defrost lapha ingaqalwa ngezikhathi ezimisiwe zemini nobusuku. Kodwa max. ama-defrosts ayisithupha

- Inethiwekhi I-defrost ingaqalwa ngokuxhumana kwedatha

Zonke izindlela ezishiwo zingasetshenziswa ngokungahleliwe - uma eyodwa nje yazo icushiwe, kuzoqalwa i-defrost. Lapho i-defrost iqala, izibali sikhathi ze-defrost zisethwa ku-zero.

Uma udinga i-coordinated defrost, lokhu kufanele kwenziwe ngokuxhumana kwedatha.

Okokufaka kwedijithali

Okokufaka kwedijithali kungasetshenziswa kule misebenzi elandelayo:

- Umsebenzi wokuxhumana nomnyango nge-alamu uma umnyango ubuvulwe isikhathi eside kakhulu.

- Ukuqala kwe-Defrost

- Ukuqala/ukumisa ukulawulwa

- Shintsha-ukusebenza ebusuku

- Ukuhlanzwa kwecala

- Shintshela kwesinye ireferensi yezinga lokushisa

- Mjove uvule/uvale

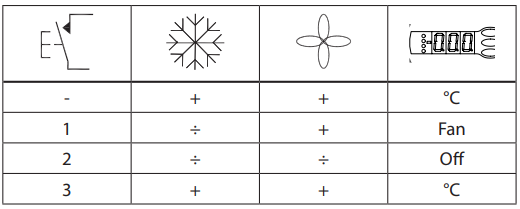

Umsebenzi wokuhlanza ikesi

Lo msebenzi wenza kube lula ukuqondisa into esebenza esiqandisini ngesigaba sokuhlanza. Ngokucindezela okuthathu kuswishi, ushintsha usuka kwesinye isigaba uye kwesinye. Ukucindezela kokuqala kumisa isiqandisi – abalandeli bayaqhubeka nokusebenza.”Kamuva”: Ukucindezela okulandelayo kumisa abalandeli.”Kuseza kamuva,”: Ukucindezela okulandelayo kuqalisa kabusha isiqandisi Izimo ezihlukene zingalandelwa esibukweni. Akukho ukuqapha izinga lokushisa ngesikhathi sokuhlanza icala. Kunethiwekhi, i-alamu yokuhlanza idluliselwa kuyunithi yesistimu. Le alamu "ingafakwa" ukuze kunikezwe ubufakazi bokulandelana kwemicimbi.

Defrost uma kudingeka

- Ngokusekelwe esikhathini sesiqandisi, lapho isikhathi sesiqandisi esihlanganisiwe sesidlulile isikhathi esinqunyiwe, i-defrost izoqalwa.

- Ngokusekelwe kuzinga lokushisa, isilawuli sizohlala silandela izinga lokushisa ku-S5. Phakathi kwama-defrosts amabili, izinga lokushisa le-S5 lizoba phansi kakhulu lapho i-evaporator ikhuphuka kakhulu (i-compressor isebenza isikhathi eside futhi idonsa izinga lokushisa le-S5 liye phansi). Uma izinga lokushisa lidlula isethi ehlukile evunyelwe, i-defrost izoqalwa.

Lo msebenzi ungasetshenziswa kuphela kumasistimu we-1:1

Ukusebenza

Bonisa

Amanani azoboniswa ngamadijithi amathathu, futhi ngesilungiselelo ungakwazi ukunquma ukuthi izinga lokushisa kufanele liboniswe ngo-°C noma ngo-°F.

Ama-diode akhipha ukukhanya (i-LED) kuphaneli yangaphambili

Kunamaledi ephaneli langaphambili azokhanya uma i-relay engumnikazi icushiwe.

Ama-diode akhipha ukukhanya azokhanya uma kune-alamu. Kulesi simo, ungadawuniloda ikhodi yephutha kusibonisi futhi ukhansele/usayine i-alamu ngokunikeza inkinobho engaphezulu ukusunduza kafushane.

I-Defrost

Ngesikhathi sokukhipha iqhwa a–d– kuboniswa esibukweni. Lokhu view izoqhubeka kuze kufike kumaminithi angu-15. ngemva kokuba ukupholisa sekuqale kabusha. Nokho, i view ka -d- kuzoyekiswa uma:

- Izinga lokushisa lifanelekile phakathi nemizuzu engu-15

- Umthetho umiswa nge-“Main Switch”

- Kuvela i-alamu yezinga lokushisa eliphezulu

Izinkinobho

Uma ufuna ukushintsha isilungiselelo, izinkinobho ezingenhla neziphansi zizokunikeza inani eliphezulu noma eliphansi, kuye ngenkinobho oyicindezelayo. Kodwa ngaphambi kokuthi ushintshe inani, kufanele ube nokufinyelela kumenyu. Lokhu ukuthola ngokucindezela inkinobho engenhla imizuzwana embalwa - uzofaka ikholomu namakhodi epharamitha. Thola ikhodi yepharamitha ofuna ukuyishintsha bese ucindezela izinkinobho ezimaphakathi kuze kube yilapho kuboniswa inani lepharamitha. Uma usushintshile inani, londoloza inani elisha ngokucindezela futhi inkinobho ephakathi nendawo.

ExampLes

Setha imenyu

- Cindezela inkinobho engenhla kuze kuvele ipharamitha ethi r01

- Cindezela inkinobho engenhla noma engezansi bese uthola ipharamitha ofuna ukuyishintsha

- Cindezela inkinobho ephakathi kuze kuvele inani lepharamitha

- Cindezela inkinobho engenhla noma engezansi bese ukhetha inani elisha

- Cindezela inkinobho ephakathi futhi ukuze ufake inani. I-Cutout alar, i-alamu yokudlulisa / irisidi/bona ikhodi ye-alamu

- Cindezela kafushane inkinobho engenhla

- Uma kukhona amakhodi amaningana e-alamu, atholakala ku-rolling stack. Cindezela inkinobho ephezulu kakhulu noma ephansi ukuze uskene isitaki esigoqayo.

Setha izinga lokushisa

- Cindezela inkinobho ephakathi kuze kubonakale inani lokushisa

- Cindezela inkinobho engenhla noma engezansi bese ukhetha inani elisha

- Cindezela inkinobho ephakathi ukuze ukhethe isilungiselelo

UManuel uqala noma amise ukuncibilika

- Cindezela inkinobho engezansi imizuzwana emine. Bona izinga lokushisa kunzwa ye-defrost

- Cindezela kafushane inkinobho engezansi. Uma ingekho inzwa ekhweziwe, "hhayi" izovela.

100% tight

Izinkinobho nophawu kufakwe ngaphambili. Indlela ekhethekile yokubumba ihlanganisa ipulasitiki yangaphambili eqinile, izinkinobho ezithambile kanye nophawu, ukuze zibe yingxenye ebalulekile yephaneli yangaphambili. Azikho izimbobo ezingathola umswakama noma ukungcola.

| Amapharamitha | Isilawuli | Okuncane.- inani | Ubuningi.- inani | Ifekthri setting | Isilungiselelo sangempela | |||

| Umsebenzi | Amakhodi | EKC

202A |

EKC

202B |

EKC

202C |

||||

| Ukusebenza okuvamile | ||||||||

| Izinga lokushisa (set point) | — | -50°C | 50°C | 2°C | ||||

| I-Thermostat | ||||||||

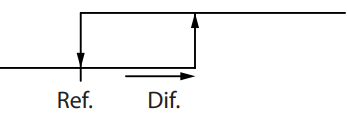

| Umehluko | r01 | 0,1 K | 20 K | 2 K | ||||

| Ubukhulu. umkhawulo wokusetha iphuzu | r02 | -49°C | 50°C | 50°C | ||||

| Okuncane. umkhawulo wokusetha iphuzu | r03 | -50°C | 49°C | -50°C | ||||

| Ukulungiswa kwenkomba yokushisa | r04 | -20 k | 20 K | 0.0 K | ||||

| Iyunithi yezinga lokushisa (°C/°F) | r05 | °C | °F | °C | ||||

| Ukulungiswa kwesiginali evela ku-Sair | r09 | -10 k | 10 K | 0 K | ||||

| Isevisi eyenziwa mathupha(-1), umthethonqubo wokumisa(0), umthethonqubo wokuqala (1) | r12 | -1 | 1 | 1 | ||||

| Ukususwa kwereferensi ngesikhathi sokusebenza ebusuku | r13 | -10 k | 10 K | 0 K | ||||

| Ukwenza kusebenze i-reference displacement r40 | r39 | VALIWE | on | VALIWE | ||||

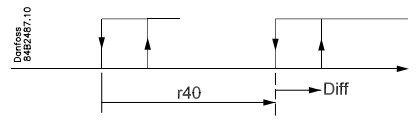

| Ivelu of reference displacement (ukwenziwa kusebenze ngo-r39 noma DI) | r40 | -50 k | 50 K | 0 K | ||||

| I-alamu | ||||||||

| Ukubambezeleka kwe-alamu yezinga lokushisa | A03 | 0 imiz | 240 imiz | 30 imiz | ||||

| Ukubambezeleka kwe-alamu yomnyango | A04 | 0 imiz | 240 imiz | 60 imiz | ||||

| Ukubambezeleka kwe-alamu yezinga lokushisa ngemva kokumiswa kweqhwa | A12 | 0 imiz | 240 imiz | 90 imiz | ||||

| Umkhawulo we-alamu ophezulu | A13 | -50°C | 50°C | 8°C | ||||

| Umkhawulo we-alamu ophansi | A14 | -50°C | 50°C | -30°C | ||||

| Ukubambezeleka kwe-alamu DI1 | A27 | 0 imiz | 240 imiz | 30 imiz | ||||

| Umkhawulo we-alamu ophezulu wezinga lokushisa le-condenser (o70) | A37 | 0°C | 99°C | 50°C | ||||

| I-Compressor | ||||||||

| Okuncane. Ngesikhathi | c01 | 0 imiz | 30 imiz | 0 imiz | ||||

| Okuncane. ISIKHATHI esingasebenzi | c02 | 0 imiz | 30 imiz | 0 imiz | ||||

| I-Compressor relay kumele ikhiphe futhi iphume ngokuphambene (i-NC-function) | c30 | 0 / VALIWE | 1 / ku | 0 / VALIWE | ||||

| I-Defrost | ||||||||

| Indlela ye-Defrost (ayikho/EL/gas) | d01 | cha | igesi | EL | ||||

| Defrost stop lokushisa | d02 | 0°C | 25°C | 6°C | ||||

| Isikhawu phakathi kokuqala kwe-defrost | d03 | 0 amahora | 48 amahora | 8 amahora | ||||

| Ubukhulu. ubude be-defrost | d04 | 0 imiz | 180 imiz | 45 imiz | ||||

| Ukushintshwa kwesikhathi ku-cutin of defrost ekuqaleni | d05 | 0 imiz | 240 imiz | 0 imiz | ||||

| Isikhathi sokuphumula | d06 | 0 imiz | 60 imiz | 0 imiz | ||||

| Ukubambezeleka kokuqala kwefeni ngemva kokumiswa kwesithwathwa | d07 | 0 imiz | 60 imiz | 0 imiz | ||||

| Izinga lokushisa lokuqala labalandeli | d08 | -15°C | 0°C | -5°C | ||||

| I-Fan cutin ngesikhathi sokushisa

0: Kumisiwe 1: Ukugijima phakathi naso sonke isigaba 2: Ukugijima ngesikhathi sesigaba sokushisa kuphela |

d09 | 0 | 2 | 1 | ||||

| Inzwa ye-Defrost (0=isikhathi, 1=S5, 2=Sair) | d10 | 0 | 2 | 0 | ||||

| Ubukhulu. isikhathi sesiqandisi esihlanganisiwe phakathi kwama-defrosts amabili | d18 | 0 amahora | 48 amahora | 0 amahora | ||||

| I-Defrost lapho idingeka - ukuhlukahluka okuvunyelwe kwezinga lokushisa le-S5 phakathi nokwakheka kwesithwathwa. Vuliwe

isitshalo esimaphakathi khetha 20 K (=off) |

d19 | 0 K | 20 K | 20 K | ||||

| Abalandeli | ||||||||

| Yima abalandeli ku-cutout compressor | F01 | cha | yebo | cha | ||||

| Ukubambezeleka kokuma kwabalandeli | F02 | 0 imiz | 30 imiz | 0 imiz | ||||

| Izinga lokushisa lokumisa abalandeli (S5) | F04 | -50°C | 50°C | 50°C | ||||

| Isikhathi sangempela sewashi | ||||||||

| Izikhathi eziyisithupha zokuqala zokuncibilika. Ukusetha amahora.

0 = VALIWE |

t01-t06 | 0 amahora | 23 amahora | 0 amahora | ||||

| Izikhathi eziyisithupha zokuqala zokuncibilika. Ukusethwa kwamaminithi.

0 = VALIWE |

t11-t16 | 0 imiz | 59 imiz | 0 imiz | ||||

| Iwashi - Ukusetha amahora | t07 | 0 amahora | 23 amahora | 0 amahora | ||||

| Iwashi - Ukusetha umzuzu | t08 | 0 imiz | 59 imiz | 0 imiz | ||||

| Iwashi – Ukusetha usuku | t45 | 1 | 31 | 1 | ||||

| Iwashi – Ukulungiselelwa kwenyanga | t46 | 1 | 12 | 1 | ||||

| Iwashi - Ukuhlelwa konyaka | t47 | 0 | 99 | 0 | ||||

| Okunhlobonhlobo | ||||||||

| Ukubambezeleka kwamasignali okukhiphayo ngemva kokuhluleka kwamandla | o01 | 0 s | 600 s | 5 s | ||||

| Isiginali yokokufaka ku-DI1. Umsebenzi:

0=ayisetshenziswanga. 1=isimo ku-DI1. 2=umsebenzi womnyango one-alamu uma uvuliwe. 3=i-alamu yomnyango uma ivuliwe. 4=ukuqala kokuncibilika (i-pulse-signal). 5=ext.iswishi enkulu. 6=ukusebenza kwasebusuku 7=shintsha inkomba (i-r40 izocushwa) 8=umsebenzi we-alamu lapho ivaliwe. 9=umsebenzi we-alamu- tion uma ivuliwe. 10=ukuhlanzwa kwekesi (i-pulse signal). 11=Jova uma uvuliwe. |

o02 | 0 | 11 | 0 | ||||

| Ikheli lenethiwekhi | o03 | 0 | 240 | 0 | ||||

| Iswishi yokuvula/ukuvala (umlayezo wephinikhodi yesevisi) | o04 | VALIWE | ON | VALIWE | ||||

| Ikhodi yokufinyelela 1 (zonke izilungiselelo) | o05 | 0 | 100 | 0 | ||||

| Uhlobo lwenzwa esetshenzisiwe (Pt/PTC/NTC) | o06 | Pt | ntc | Pt | ||||

| Isinyathelo sokubonisa = 0.5 (okujwayelekile okungu-0.1 kunzwa ye-Pt) | o15 | cha | yebo | cha | ||||

| Isikhathi esiphezulu sokubamba ngemva kokumiswa kweqhwa okuhlanganisiwe | o16 | 0 imiz | 60 imiz | 20 | ||||

| Ukucushwa komsebenzi wokukhanya (i-relay 4)

1=VULIWE phakathi nokusebenza kosuku. 2=VULIWE / VALIWE ngokuxhumana kwedatha. 3=ON ulandela i-DI- umsebenzi, lapho i-DI ikhethelwa umsebenzi womnyango noma i-alamu yomnyango |

o38 | 1 | 3 | 1 | ||||

| Ukwenza kusebenze i-relay yokukhanya (kuphela uma o38=2) | o39 | VALIWE | ON | VALIWE | ||||

| Ukuhlanzwa kwecala. 0=akukho ukuhlanzwa kwekesi. 1=Abalandeli kuphela. 2=Konke okukhiphayo Kuvaliwe. | o46 | 0 | 2 | 0 | ||||

| Ikhodi yokufinyelela 2 (ukufinyelela ngokwengxenye) | o64 | 0 | 100 | 0 | ||||

| Londoloza izilungiselelo zamanje zezilawuli kukhiye wokuhlela. Khetha inombolo yakho. | o65 | 0 | 25 | 0 | ||||

| Layisha isethi yezilungiselelo kusuka kukhiye wokuhlela (owawulondolozwe ngaphambilini ngomsebenzi we-o65) | o66 | 0 | 25 | 0 | ||||

| Shintshanisa izilungiselelo zasembonini zezilawuli ngezilungiselelo zamanje | o67 | VALIWE | On | VALIWE | ||||

| Uhlelo lokusebenza oluhlukile lwenzwa ye-S5 (gcina ukulungiselelwa kokuthi 0 uma isetshenziswa njengenzwa yokuncibilika, ngaphandle kwalokho 1 = inzwa yomkhiqizo kanye no-2 = inzwa ye-condenser ene-alamu) | o70 | 0 | 2 | 0 | ||||

| Khetha isicelo sokudluliswa kwe-4: 1=defrost/light, 2= alarm | o72 | defrost/

I-alamu |

Ukukhanya /

I-alamu |

1 | 2 | 2 | ||

| Isevisi | ||||||||

| Izinga lokushisa likalwe ngenzwa ye-S5 | u09 | |||||||

| Isimo kokokufaka kwe-DI1. ku/1=kuvaliwe | u10 | |||||||

| Isimo sokusebenza ebusuku (kuvuliwe noma kuvaliwe) 1=kuvaliwe | u13 | |||||||

| Funda inkomba yamanje yomthetho | u28 | |||||||

| Isimo ekudluliselweneni kokupholisa (Singalawulwa mathupha, kodwa kuphela uma r12=-1) | u58 | |||||||

| Isimo sokudluliswa kwabalandeli (Singalawulwa mathupha, kodwa kuphela uma r12=-1) | u59 | |||||||

| Isimo ekudlulisweni kwe-defrost. (Ingalawulwa ngesandla, kodwa kuphela uma r12=-1) | u60 | |||||||

| Izinga lokushisa likalwa ngenzwa ye-Sair | u69 | |||||||

| Isimo ku-relay 4 (i-alamu, i-defrost, ukukhanya). (Ingalawulwa ngesandla, kodwa kuphela lapho

r12=-1) |

u71 | |||||||

Isilungiselelo sasefekthri

Uma udinga ukubuyela kumanani asethwe njengasekuqaleni, kungenziwa ngale ndlela:

- Sika umthamo wokunikezelatage kusilawuli

- Gcina izinkinobho ezingenhla neziphansi zicindezelekile ngesikhathi esifanayo njengoba uxhuma kabusha ivolumu yokunikezelatage.

| Iphutha ikhodi isibonisi | Isibonisi sekhodi ye-alamu | Isimo ikhodi isibonisi | |||

| E1 | Iphutha kusilawuli | A 1 | I-alamu yokushisa ephezulu | S0 | Ukulawula |

| E6 | Shintsha ibhethri + iwashi lokuhlola | A 2 | I-alamu yezinga lokushisa eliphansi | S1 | Ilinde ukuphela kwe-defrost ehlanganisiwe |

| E 27 | Iphutha lenzwa ye-S5 | A 4 | I-alamu yomnyango | S2 | I-Compressor yesikhathi |

| E 29 | Iphutha lenzwa ye-Sair | A 5 | Ubukhulu. Bamba isikhathi | S3 | I-Compressor ye-OFF-time |

| A 15 | I-alamu ye-DI 1 | S4 | Isikhathi sokuphumula | ||

| A 45 | Imodi yokulinda | S10 | Isiqandisi simiswe ngokushintsha okukhulu | ||

| A 59 | Ukuhlanzwa kwecala | S11 | Isiqandisi simiswe yi-thermostat | ||

| A 61 | I-alamu ye-Condenser | S14 | Defrost ukulandelana. Ukuqothula | ||

| S15 | Defrost ukulandelana. Ukubambezeleka kwabalandeli | ||||

| S16 | Isiqandisi simile ngenxa ye-DI evulekile

okokufaka |

||||

| S17 | Umnyango uvuliwe (vula okokufaka kwe-DI) | ||||

| S20 | Ukupholisa izimo eziphuthumayo | ||||

| S25 | Ukulawula okuphumayo mathupha | ||||

| S29 | Ukuhlanzwa kwecala | ||||

| S32 | Ukubambezeleka kokukhiphayo ekuqaleni | ||||

| hhayi | Izinga lokushisa le-defrost alikwazi ukwehliswa-

kudlalwa. Kukhona ukuma okusekelwe esikhathini |

||||

| -d- | Ukuncibilika kuyaqhubeka / Ukupholisa kokuqala ngemva

khipha |

||||

| PS | Kudingeka iphasiwedi. Setha iphasiwedi | ||||

Qalisa:

Umthethonqubo uqala lapho i-voltage ivuliwe.

- Dlula kunhlolovo yezilungiselelo zefekthri. Yenza noma yiziphi izinguquko ezidingekayo kumapharamitha afanele.

- Okwenethiwekhi. Setha ikheli kokuthi o03 bese ulidlulisela esangweni/ iyunithi yesistimu enokusetha okuthi o04.

Imisebenzi

Nansi incazelo yemisebenzi ngayinye. Isilawuli siqukethe kuphela le ngxenye yemisebenzi. Cf. inhlolovo yemenyu.

| Umsebenzi | Ipharamitha | Ipharamitha ngokusebenza nge-data com- umculo |

| Okuvamile isibonisi | ||

| Ngokuvamile izinga lokushisa elivela kunzwa ye-thermostat i-Sair liyaboniswa. | Bonisa umoya (u69) | |

| I-Thermostat | Ukulawula i-thermostat | |

| Setha iphuzu

Umthethonqubo usekelwe kunani elimisiwe kanye nokusuka endaweni, uma kusebenza. Inani lisethwa ngokucindezela inkinobho ephakathi. Inani elimisiwe lingakhiywa noma likhawulelwe kububanzi ngezilungiselelo eziku-r02 no-r03. Ireferensi nganoma yisiphi isikhathi ingabonwa kokuthi ”u28 Temp. ref” |

Ukusika °C | |

| Umehluko

Uma izinga lokushisa liphakeme kunereferensi + umehluko omisiwe, i-compressor relay izosikwa phakathi. Izonqamuka futhi lapho izinga lokushisa lehla kunkomba emisiwe. |

r01 | Umehluko |

| Setha iphuzu umkhawulo

Ibanga lesilungiselelo lesilawuli lephoyinti elimisiwe lingase lincishiswe, ukuze amanani aphezulu kakhulu noma aphansi kakhulu angasethwa ngephutha – kube nomonakalo owumphumela. |

||

| Ukuze ugweme ukusetha okuphezulu kakhulu kwephoyinti elimisiwe, ubuningi. inani lereferensi elivumelekile kufanele lehliswe. | r02 | Ukusika okuphezulu °C |

| Ukuze ugweme ukusetha okuphansi kakhulu kwephoyinti elimisiwe, imiz. inani lereferensi elivumelekile kufanele lenyuswe. | r03 | Ukusika okuncane °C |

| Ukulungiswa kwezinga lokushisa lesibonisi

Uma izinga lokushisa emikhiqizweni kanye nezinga lokushisa elitholwe isilawuli kungafani, ukulungiswa kwe-offset kwezinga lokushisa elibonisiwe kungenziwa. |

r04 | I-Disp. I-Adj. K |

| Iyunithi yezinga lokushisa

Setha lapha uma isilawuli sizobonisa amanani okushisa ku-°C noma ku-°F. |

r05 | Temp. iyunithi

°C=0. / °F=1 (U-°C kuphela ku-AKM, kungakhathaliseki ukuthi isiphi isilungiselelo) |

| Ukulungisa of isignali kusuka eSair

Ukunxeshezelwa okungenzeka ngekhebula lenzwa ende |

r09 | Lungisa i-Sair |

| Qala / stop of esiqandisini

Ngalesi silungiselelo isiqandisi singaqalwa, simiswe noma ukukhipha mathupha kokuphumayo kungavunyelwa. Ukuqala / ukumiswa kwesiqandisi nakho kungafezwa ngomsebenzi wokushintsha wangaphandle oxhunywe kokokufaka kwe-DI. Isiqandisi esimisiwe sizonikeza "i-alamu yokulinda". |

r12 | Ukushintsha Okuyinhloko

1: Qala 0: Yima -1: Ukulawula okwenziwa ngesandla kokuphumayo kuvunyelwe |

| Inani lokubuyisela emuva ebusuku

Ireferensi ye-thermostat izoba iphoyinti elimisiwe kanye naleli nani uma isilawuli sishintsha ukuya emsebenzini ebusuku. (Khetha inani elingalungile uma kuzoba nokunqwabelana okubandayo.) |

r13 | I-offset yasebusuku |

| Ukwenza kusebenze ukususwa kwereferensi

Uma umsebenzi ushintshwa ukuze uthi ON umehluko we-thermostat uzokwenyuswa ngenani elingu-r40. Ukwenza kusebenze futhi kungenzeka ngokufaka i-DI (echazwe ku-o02).

|

r39 | Th. offset |

| Inani lokususwa kwereferensi

Ireferensi ye-thermostat namanani e-alamu ashintshwa ngenani lamadigri alandelayo lapho ukususwa kucushiwe. Ukusebenza kungenziwa nge-r39 noma nge-put DI |

r40 | Th. susa K |

| Ukubuyela emuva ebusuku

(ukuqala kwesignali yasebusuku) |

| I-alamu | Izilungiselelo ze-alamu | |

| Isilawuli singanikeza i-alamu ezimeni ezahlukene. Uma kune-alamu wonke ama-light-emitting diode (LED) azokhanyisa kuphaneli yangaphambili yesilawuli, futhi i-alamu izonqamuka. | Ngokuxhumana kwedatha, ukubaluleka kwama-alamu ngamanye kungachazwa. Ukusetha kwenziwa kumenyu "yezindawo ze-alamu". | |

| Ukubambezeleka kwe-alamu (ukubambezeleka kwe-alamu okufushane)

Uma eyodwa kwamanani amabili omkhawulo yeqiwe, umsebenzi wesibali sikhathi uzoqala. I-alamu ngeke qala ukusebenza kuze kudlule isikhathi esimisiwe sokulibaziseka. Ukubambezeleka kwesikhathi kusethwe ngamaminithi. |

A03 | Ukubambezeleka kwe-alamu |

| Ukubambezeleka kwesikhathi kwe-alamu yomnyango

Ukubambezeleka kwesikhathi kusethwe ngamaminithi. Umsebenzi uchazwa ku-o02. |

A04 | I-DoorOpen del |

| Ukulibaziseka kwesikhathi sokupholisa (ukubambezeleka okude kwe-alamu)

Lesi sikhathi sokulibaziseka sisetshenziswa ngesikhathi sokuqala, ngesikhathi sokumiswa kweqhwa, futhi ngokushesha ngemva kokumiswa kweqhwa. Kuzoba noshintsho ekubambezelekeni kwesikhathi esijwayelekile (A03) uma izinga lokushisa lehlile ngaphansi komkhawulo we-alamu omisiwe. Ukubambezeleka kwesikhathi kusethwe ngamaminithi. |

A12 | Donsela phansi del |

| Umkhawulo we-alamu ophezulu

Lapha usetha ukuthi i-alamu yezinga lokushisa eliphezulu izoqala nini. Inani eliwumkhawulo lisethwe ku-°C (inani eliphelele). Inani elilinganiselwe lizokhushulwa phakathi nokusebenza ebusuku. Inani liyafana nalelo elimiselwe ukubuyisela emuva ebusuku, kodwa lizokhushulwa kuphela uma inani liphozithivu. Inani elilinganiselwe lizophinde liphakanyiswe mayelana nokugudluzwa kwereferensi u-r39. |

A13 | I-HighLim Air |

| Umkhawulo we-alamu ophansi

Lapha usetha ukuthi i-alamu yezinga lokushisa eliphansi izoqala nini. Inani eliwumkhawulo lisethwe ku-°C (inani eliphelele). Inani elilinganiselwe lizophinde liphakanyiswe mayelana nokugudluzwa kwereferensi u-r39. |

A14 | I-LowLim Air |

| Ukubambezeleka kwe-alamu ye-DI

Okokufaka kokusika/ukusika kuzoholela ku-alamu lapho ukubambezeleka kwesikhathi kudlulile. Umsebenzi uchaziwe kwe o02. |

A27 | I-AI.Libazisa i-DI |

| Umkhawulo we-alamu ophezulu wokushisa kwe-condenser

Uma inzwa ye-S5 isetshenziselwa ukuqapha izinga lokushisa le-condenser kufanele usethe inani lapho i-alamu izosebenza khona. Inani lisethwe kokuthi °C. Incazelo ye-S5 njengenzwa ye-condenser ifinyelelwa ku-o70. I-alamu isethwe kabusha futhi ibe ngu-10 K ngaphansi kwezinga lokushisa elibekiwe. |

A37 | Contemp Al. |

| Setha kabusha i-alamu |

| I-Compressor | Ukulawula i-Compressor | |

| I-compressor relay isebenza ngokubambisana ne-thermostat. Lapho i-thermostat ibiza isiqandisi kuzosebenza ukudluliselwa kwe-compressor. | ||

| Izikhathi zokugijima

Ukuze uvimbele ukusebenza okungajwayelekile, amanani angasethwa ngesikhathi okufanele i-compressor isebenze uma isiqalile. Futhi kufanele kumiswe isikhathi esingakanani? Izikhathi zokusebenza azibonwa lapho ama-defrosts eqala. |

||

| Okuncane. NGESIKHATHI (ngamaminithi) | c01 | Okuncane. Ngesikhathi |

| Okuncane. I-OFF-time (ngamaminithi) | c02 | Okuncane. Isikhathi sokuphumula |

| Umsebenzi wokudlulisela emuva obuyiselwe emuva we-compressor relay

0: Umsebenzi ojwayelekile lapho i-relay inqamula lapho isiqandisi sifunwa 1: Umsebenzi ohlehlisiwe lapho i-relay inqamuka lapho isiqandisi sifunwa (le wiring pro- ithola umphumela wokuthi kuzoba nesiqandisi uma umthamo wokuhlinzekatage kusilawuli sehlulekile). |

c30 | I-Cmp edluliselwe NC |

| I-Defrost | Ukulawula i-Defrost | |

| Isilawuli siqukethe umsebenzi wesikhathi omiswa uzirothi ngemva kokuqala ngakunye kwe-defrost. Umsebenzi we-timer uzoqala ukuncibilika uma/uma isikhathi sokuphumula sesidlulile.

Umsebenzi wesibali sikhathi uqala lapho ivolumutagU-e uxhumeke kusilawuli, kodwa ukhishwa okokuqala ngqa ngokulungiselelwa kokuthi d05. Uma kukhona ukuhluleka kwamandla, inani lesikhathi lizogcinwa futhi liqhubeke ukusuka lapha lapho amandla ebuya. Lokhu kusebenza kwe-timer kungasetshenziswa njengendlela elula yokuqala ukuncibilika, kodwa kuzohlala kusebenza njengokuncibilika kokuphepha uma okunye kokuncishiswa kweqhwa okulandelayo kungatholwa. Isilawuli siqukethe newashi lesikhathi sangempela. Ngokusebenzisa izilungiselelo zaleli washi nezikhathi zezikhathi ezidingekayo zokuqeda isithwathwa, ukumiswa kweqhwa kungaqala ngezikhathi ezimisiwe zosuku. Uma kunobungozi bokungaphumeleli kwamandla izikhathi ezingaphezu kwamahora amane, imojuli yebhethri kufanele ifakwe kusilawuli. Ukuqala kwe-Defrost nakho kungenziwa ngokuxhumana kwedatha, ngamasignali okuxhumana noma ngesandla Qalisa. |

||

| Zonke izindlela zokuqalisa zizosebenza kusilawuli. Imisebenzi ehlukene kufanele isethwe, ukuze ama-defrost "angafiki edilika" ngokulandelana.

I-Defrost ingenziwa ngogesi, igesi eshisayo noma i-brine. I-defrost yangempela izomiswa ngokusekelwe esikhathini noma izinga lokushisa ngesignali evela kunzwa yezinga lokushisa. |

||

| Indlela ye-Defrost

Lapha ubeka ukuthi i-defrost izofezwa ngogesi noma "okungeyona". Ngesikhathi se-defrost, i-defrost relay izosikwa phakathi. Lapho i-gas defrosting, i-compressor relay izonqanyulwa phakathi ne-defrost. |

d01 | Def. indlela |

| Defrost stop lokushisa

I-defrost imiswa ezingeni lokushisa elinikeziwe elilinganiswa ngenzwa (inzwa ichazwa ku-d10). Inani lokushisa lisethiwe. |

d02 | Def. Misa iTemp |

| Isikhawu phakathi kokuqala kwe-defrost

Umsebenzi unguziroset futhi uzoqala umsebenzi wesikhathi ekuqalweni ngakunye kwe-defrost. Uma isikhathi sesiphelile umsebenzi uzoqala ukuncibilika. Umsebenzi usetshenziswa njengesiqalo esilula sokuncibilika, noma ungasetshenziswa njengesivikelo uma isignali evamile yehluleka ukuvela. Uma kusetshenziswa i-master/slave defrost ngaphandle komsebenzi wewashi noma ngaphandle kokuxhumana kwedatha, isikhathi sokuphumula sizosetshenziswa njengobukhulu. isikhathi phakathi kwama-defrosts. Uma isiqalo sokuncibilika ngokuxhumana kwedatha singenzeki, isikhathi sokuphumula sizosetshenziswa njengobuningi. isikhathi phakathi kwama-defrosts. Uma kukhona ukuncibilika ngokusebenza kwewashi noma ukuxhumana kwedatha, isikhathi sokuphumula kufanele simiselwe isikhathi eside kunaleso esihleliwe, njengoba isikhathi sokuphumula sizoqala ukuncibilika okuyothi ngokuhamba kwesikhathi kulandelwe yileso esihleliwe. Ngokuphathelene nokuhluleka kwamandla, isikhathi sokuphumula sizogcinwa, futhi lapho amandla ebuya isikhathi sokuphumula sizoqhubeka ukusuka kunani eligciniwe. Isikhathi sokuphumula asisebenzi uma sisethelwe ku-0. |

d03 | Isikhawu se-Def (0=off) |

| Ubude besikhathi sokuncibilika

Lesi silungiselelo yisikhathi sokuphepha ukuze ukuncibilika kumiswe uma bekungakaze kube khona ukuma okusekelwe ezingeni lokushisa noma ngokumiswa kweqhwa okuhlanganisiwe. (Isilungiselelo kuzoba isikhathi sokumisa uma i-d10 ikhethwa ukuthi ibe ngu-0) |

d04 | I-Max Def. isikhathi |

| Isikhathi stagi-gering ye-defrost cut-ins ngesikhathi sokuqala

Umsebenzi ufanelekile kuphela uma unemishini yesiqandisi eminingana noma amaqembu lapho ufuna ukuthi i-defrost ibe stagmaqondana nomunye. Umsebenzi futhi ubalulekile kuphela uma ukhethe ukuncishiswa kweqhwa ngokuqala kwesikhawu (d03). Umsebenzi ubambezela isikhathi sesikhawu esingu-d03 ngenani elimisiwe lamaminithi, kodwa ukwenza kanye kuphela, futhi lokhu ekuncishisweni kweqhwa kokuqala okwenzeka lapho ivolumutagi-e ixhunywe kusilawuli. Umsebenzi uzosebenza ngemva kokuhluleka ngakunye ngakunye. |

d05 | Isikhathi Stagg. |

| Isikhathi sokuphumula

Lapha usetha isikhathi okumele sidlule kusukela ekuncipheni futhi kuze kube yilapho i-compressor iqala futhi. (Isikhathi lapho amanzi econsa ku-evaporator). |

d06 | Isikhathi se-DripOff |

| Ukubambezeleka kwefeni kuqala ngemva kokumiswa kwesithwathwa

Lapha usetha isikhathi okumele sidlule kusukela ekuqaleni kwe-compressor ngemva kokumiswa kweqhwa kuze kube yilapho isiphephetha-moya siqala futhi. (Isikhathi lapho amanzi “eboshelwa” ku-evaporator). |

d07 | I-FanStartDel |

| Izinga lokushisa lokuqala labalandeli

I-fan ingase futhi iqalwe ngaphambi kwesikhathi kunalokho kushiwo ngaphansi kokuthi "Ukubambezeleka kokuqala kwabalandeli ngemva kokumiswa kweqhwa", uma inzwa ye-defrost S5 ibhalisa inani eliphansi kunaleli elibekwe lapha. |

d08 | I-FanStartTemp |

| I-fan inqamule ngesikhathi sokushisa

Lapha ungasetha ukuthi ingabe ifeni kufanele isebenze ngesikhathi sokumiswa kweqhwa. 0: Imisiwe (Igijima ngesikhathi sokupompa phansi) 1: Ukugijima phakathi naso sonke isigaba 2: Ukugijima ngesikhathi sesigaba sokushisa kuphela. Ngemva kwalokho kume |

d09 | FanDuringDef |

| Inzwa ye-Defrost

Lapha uchaza inzwa ye-defrost. 0: Lutho, i-defrost isekelwe esikhathini 1: S5 2: shwi |

d10 | I-DefStopSens. |

| I-Defrost ngokufunwa - isikhathi sesiqandisi esihlanganisiwe

Setha lapha isikhathi sesiqandisi esivunyelwe ngaphandle kwama-defrosts. Uma isikhathi sesidlulile, i-defrost izoqala. Ngokusethwa = 0 umsebenzi uyasikwa. |

d18 | I-MaxTherRunT |

| Defrost uma kudingeka - izinga lokushisa le-S5

Isilawuli sizolandela ukusebenza kwe-evaporator, futhi ngezibalo zangaphakathi nezilinganiso zezinga lokushisa le-S5 sizokwazi ukuqalisa ukumisa isithwathwa lapho ukuhluka kwezinga lokushisa le-S5 kuba kukhulu kunalokho okudingekayo. Lapha usetha ukuthi isilayidi sezinga lokushisa le-S5 sikhulu kangakanani esingavunyelwa. Uma inani lidluliswa, i-defrost izoqala. Umsebenzi ungasetshenziswa kuphela ezinhlelweni ze-1:1 lapho izinga lokushisa elihwamukayo lizoba phansi ukuze kuqinisekiswe ukuthi izinga lokushisa lomoya lizogcinwa. Ezinhlelweni ezimaphakathi umsebenzi kumele unqanyulwe. Ngokusethwa = 20 umsebenzi uyasikwa |

d19 | I-CutoutS5Dif. |

| Uma ufisa ukubona izinga lokushisa kunzwa ye-S5, cindezela inkinobho yesilawuli ephansi kakhulu. | I-Defrost temp. | |

| Uma ufisa ukuqalisa i-defrost eyengeziwe, cindezela inkinobho yesilawuli ephansi kakhulu imizuzwana emine. Ungamisa i-defrost eqhubekayo ngendlela efanayo | Def Qala

Lapha ungaqala i-defrost eyenziwa ngesandla. |

|

| Bamba Ngemva kweDef

Ibonisa VULIWE lapho isilawuli sisebenza ngokuncibilika okuhlanganisiwe. |

||

| Defrost State Status on defrost

1= phompa phansi / ncibilikisa |

||

| Umlandeli | Ukulawula abalandeli | |

| I-fan yema kusiminyanisa

Lapha ungakhetha ukuthi ingabe ifeni izomiswa yini uma i-compressor inqanyulwa |

F01 | Isitobhi sabalandeli CO

(Yebo = Umlandeli umile) |

| Ukubambezeleka kokuma kwefeni lapho i-compressor inqanyulwa

Uma ukhethe ukumisa isiphephetha-moya lapho i-compressor inqanyulwa, ungabambezela ukuma kwefeni lapho i-compressor iyekile. Lapha ungasetha ukubambezeleka kwesikhathi. |

F02 | Umlandeli del. CO |

| Izinga lokushisa lokumisa abalandeli

Umsebenzi umisa abalandeli esimweni sephutha, ukuze bangakwazi ukunikeza amandla kumshini. Uma inzwa ye-defrost ibhalisa izinga lokushisa eliphezulu kunaleli elibekwe lapha, abalandeli bazomiswa. Kuzoqalwa kabusha ngo-2 K ngaphansi kwesilungiselelo. Umsebenzi awusebenzi ngesikhathi sokumiswa kweqhwa noma ukuqalisa ngemva kokumiswa kweqhwa. Ngokusetha +50°C umsebenzi uyaphazamiseka. |

F04 | I-FanStopTemp. |

| Umsebenzi we-defrosting wangaphakathi/iwashi | ||

| (Ayisetshenziswa uma ishejuli yokuqeda isithwathwa yangaphandle isetshenziswa ngokuxhumana kwedatha.) Kungasethwa izikhathi ezingafika kweziyisithupha ukuze kuqalwe iqhwa usuku lonke. | ||

| Ukuqala kwe-Defrost, ukulungiselelwa kwehora | t01-t06 | |

| Isiqalo sokuncibilika, ukulungiselelwa kweminithi (1 no-11 kuhlangene, njll.) Uma konke okuthi t01 kuya ku-t16 kulingana no-0, iwashi ngeke liqale ukuncibilika. | t11-t16 | |

| Iwashi lesikhathi sangempela

Ukusetha iwashi kuyadingeka kuphela uma kungekho ukuxhumana kwedatha. Uma kwenzeka ukwehluleka kwamandla okungaphansi kwamahora amane, umsebenzi wewashi uzogcinwa. Uma ukhweza imojuli yebhethri umsebenzi wewashi ungagcinwa isikhathi eside. (EKC 202 kuphela) |

||

| Iwashi: Ukulungiselelwa kwehora | t07 | |

| Iwashi: Ukulungiselelwa kwemizuzu | t08 | |

| Iwashi: Ukulungiselelwa kosuku | t45 | |

| Iwashi: Ukulungiselelwa kwenyanga | t46 | |

| Iwashi: Ukulungiselelwa konyaka | t47 |

| Okunhlobonhlobo | Okunhlobonhlobo | |

| Ukubambezeleka kwesignali yokuphumayo ngemva kokuqala

Ngemva kokuqalisa noma ukuphelelwa amandla, imisebenzi yesilawuli ingase ibambezeleke ukuze kugwenywe ukulayishwa ngokweqile kwenethiwekhi yokuphakela ugesi. Lapha ungasetha ukubambezeleka kwesikhathi. |

o01 | I-DelayOfOutp. |

| Isiginali yokufaka yedijithali – DI

Isilawuli sinokufaka kwedijithali okungase kusetshenziselwe omunye wale misebenzi elandelayo: Valiwe: Okokufaka akusetshenzisiwe 1) Isimo sokuboniswa komsebenzi wothintana naye 2) Umsebenzi womnyango. Uma okokufaka kuvuliwe kubonisa ukuthi umnyango uvuliwe. Isiqandisi nabalandeli kumisiwe. Uma isilungiselelo sesikhathi kokuthi “A04” sidlula, kuzonikezwa i-alamu futhi isiqandisi sizoqaliswa kabusha. 3) I-alamu yomnyango. Uma okokufaka kuvuliwe kubonisa ukuthi umnyango uvuliwe. Uma ukusetha isikhathi kokuthi “A04” kudluliswa, kuzoba ne-alamu. 4) I-Defrost. Umsebenzi uqalwa ngesignali ye-pulse. Isilawuli sizobhalisa lapho okokufaka kwe-DI kwenziwa kusebenze. Isilawuli sizobe sesiqala umjikelezo wokususa uqhwa. Uma isignali izotholwa izilawuli ezimbalwa kubalulekile ukuthi KONKE ukuxhumana kufakwe ngendlela efanayo (DI ukuya ku-DI kanye ne-GND kuya ku-GND). 5) Iswishi eyinhloko. Ukulawulwa kwenziwa lapho okokufaka kufushane, futhi umthetho uyamiswa lapho okokufaka kufakwa. VALIWE. 6) Ukusebenza ebusuku. Uma okokufaka kufushane, kuzoba nomthethonqubo wokusebenza ebusuku. I-7) Ukususwa kwereferensi lapho i-DI1 ine-circuited short-circuited. Ukususwa ngo-“r40”. 8) Umsebenzi we-alamu ohlukile. I-alamu izonikezwa uma okokufaka kufinyezwa. 9) Umsebenzi we-alamu ohlukile. I-alamu izonikezwa uma okokufaka kuvulwa. (Ku-8 no-9 ukubambezeleka kwesikhathi kusethwe ku-A27) 10) Ukuhlanzwa kwecala. Umsebenzi uqalwa ngesignali ye-pulse. Cf. nencazelo ekhasini lesi-4. 11) Faka umjovo uvule/uvale. Vala uma i-DI ivuliwe. |

o02 | I-DI 1 Config.

Incazelo yenzeka ngenani lenombolo eliboniswa kwesokunxele. (0 = ivaliwe)

Isimo se-DI (Isilinganiso) Isimo samanje sokokufaka kwe-DI siboniswa lapha. VULIWE noma VALIWE. |

| Ikheli

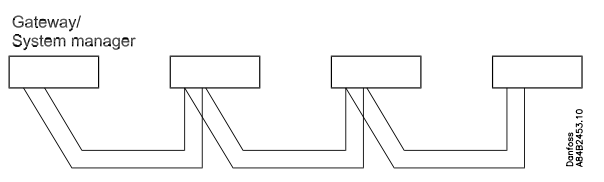

Uma isilawuli sakhelwe kunethiwekhi enokuxhumana kwedatha, kufanele sibe nekheli, futhi isango elikhulu lokuxhumana kwedatha kufanele-ke lazi leli kheli. Ukufakwa kwekhebula lokuxhumana kwedatha kushiwo kudokhumenti ehlukile, “RC8AC”. Ikheli lisethwe phakathi kuka-1 no-240, isango linqunyiwe Ikheli lithunyelwa kumphathi wesistimu lapho imenyu o04 isethwe ukuze ithi 'IVULIWE', noma uma umsebenzi wokuskena womphathi wesistimu ucushiwe. (i-o04 izosetshenziswa kuphela uma ukuxhumana kwedatha kuyi-LON.) |

Ngemva kokufaka ukuxhumana kwedatha, isilawuli singasetshenzwa ngokulingana nezinye izilawuli kuzilawuli zesiqandisi ze-ADAP-KOOL®. | |

| o03 | ||

| o04 | ||

| Ikhodi yokufinyelela 1 (Ukufinyelela kuzo zonke izilungiselelo)

Uma izilungiselelo kusilawuli kufanele zivikelwe ngekhodi yokufinyelela ungasetha inani lenombolo phakathi kuka-0 no-100. Uma kungenjalo, ungakhansela umsebenzi ngokusetha okuthi 0. (99 izokunikeza njalo. uyangena). |

o05 | – |

| Uhlobo lwenzwa

Imvamisa, kusetshenziswa inzwa ye-Pt 1000 enokunemba okukhulu kwesignali. Kodwa ungasebenzisa futhi inzwa ngenye ukunemba kwesignali. Lokho kungase kube inzwa ye-PTC 1000 noma inzwa ye-NTC (5000 Ohm ku-25°C). Zonke izinzwa ezifakiwe kufanele zibe zohlobo olufanayo. |

o06 | I-SensorConfig Pt = 0

I-PTC = 1 I-NTC = 2 |

| Bonisa isinyathelo

Yebo: Inikeza izinyathelo zika-0.5° Cha: Inikeza izinyathelo zika-0.1° |

o15 | I-Disp. Isinyathelo = 0.5 |

| Ubukhulu. isikhathi sokulinda ngemva kokuhlanganiswa kwe-defrost

Uma isilawuli sesiqedile ukumisa iqhwa, sizolinda isignali etshela ukuthi isiqandisi singaqaliswa kabusha. Uma lesi siginali yehluleka ukuvela ngesizathu esisodwa noma esinye, isilawuli sizokwenza yona ngokwayo iqala isiqandisi lapho lesi sikhathi sokulinda sesidlulile. |

o16 | I-Max HoldTime |

| Ukucushwa komsebenzi wokukhanya

1) I-relay iyanqamuka phakathi nokusebenza kosuku 2) I-relay okufanele ilawulwe ngokuxhumana kwedatha 3) I-relay okufanele ilawulwe iswishi yomnyango ichazwe ku-o02 lapho ukulungiselelwa kukhethwe khona kube ku-2 noma ku-3. Uma umnyango uvulwa i-relay izongena phakathi. Uma umnyango uvaliwe. futhi kuzoba nokubambezeleka kwesikhathi kwemizuzu emibili ngaphambi kokuba ukukhanya kucishwe. |

o38 | Ukulungisa ukukhanya |

| Ukwenza kusebenze of edluliselwe ukukhanya

I-relay yokukhanya ingenziwa isebenze lapha (uma 038=2) |

o39 | Isilawuli kude esikhanyayo |

| Ukuhlanzwa kwecala

Isimo somsebenzi singalandelwa lapha noma umsebenzi ungaqalwa mathupha. 0 = Ukusebenza okujwayelekile (akukho ukuhlanzwa) 1 = Ukuhlanza nabalandeli abasebenza. Yonke eminye imiphumela Valiwe. 2 = Ukuhlanza ngabalandeli abamisiwe. Konke okukhiphayo Kuvaliwe. Uma umsebenzi ulawulwa isignali kokokufaka kwe-DI, isimo esifanelekile singabonakala lapha kokuthi imenyu. |

o46 | Ikesi lihlanzekile |

| Ikhodi yokufinyelela 2 (Ukufinyelela ekulungiseni)

Kukhona ukufinyelela ekulungisweni kwamanani, kodwa hhayi kuzilungiselelo zokumisa. Uma izilungiselelo kusilawuli zizovikelwa ngekhodi yokufinyelela ungasetha inani lenombolo phakathi kuka-0 no 100. Uma kungenjalo, ungakhansela uhlelo ngokusetha u-0. Uma uhlelo lusetshenziswa, ngena ikhodi 1 (o05) kufanele futhi kusetshenziswe. |

o64 | – |

| Kopisha izilungiselelo zamanje zesilawuli

Ngalo msebenzi, izilungiselelo zesilawuli zingadluliselwa kukhiye wokuhlela. Ukhiye ungaqukatha amasethi ahlukene angafika kwangu-25. Khetha inombolo. Zonke izilungiselelo ngaphandle kwekheli (o03) zizokopishwa. Uma ukukopisha sekuqalile, isibonisi sibuyela ku-o65. Ngemuva kwemizuzwana emibili, ungangena kumenyu futhi futhi uhlole ukuthi ukukopisha kuyagculisa yini. Ukubonisa isibalo esingalungile kusho izinkinga. Bona ukubaluleka kusigaba somlayezo onephutha. |

o65 | – |

| Kopisha kusuka kukhiye wokuhlela

Lo msebenzi ulanda isethi yezilungiselelo ezilondolozwe ngaphambilini kusilawuli. Khetha inombolo efanele. Zonke izilungiselelo ngaphandle kwekheli (o03) zizokopishwa. Uma ukukopisha sekuqalile isibonisi sibuyela ku-o66. Ngemva kwemizuzwana emibili, ungakwazi ukubuyela emuva kumenyu futhi uhlole ukuthi ukukopisha kuyagculisa yini. Ukubonisa isibalo esingalungile kusho izinkinga. Bona ukubaluleka engxenyeni ethi Umlayezo Ongalungile. |

o66 | – |

| Londoloza njengesilungiselelo sasefekthri

Ngalesi silungiselelo ulondoloza izilungiselelo zangempela zesilawuli njengesilungiselelo esisha esiyisisekelo (ubuso bangaphambili- izilungiselelo zomlando zibhalwe phezu). |

o67 | – |

| Olunye uhlelo lokusebenza lwenzwa ye-S5

Gcina ukulungiselelwa kokungu-0 uma inzwa ichazwe njengenzwa ye-defrost ku-D10. Uma i-D10 isethwe kokuthi 0 noma 2 okokufaka kwe-S5 kungasetshenziswa njengenzwa yomkhiqizo noma inzwa ye-condenser. Lapha uchaza ukuthi yikuphi: 0: Inzwa ye-Defrost 1: Inzwa yomkhiqizo 2: Inzwa ye-Condenser ene-alamu |

o70 | I-S5 Config |

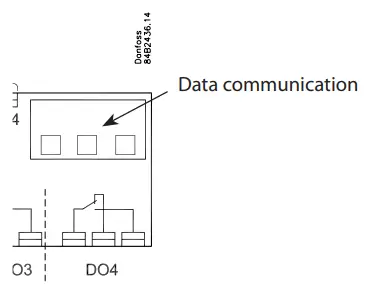

| Ukudlulisela 4

Lapha uchaza isicelo se-relay 4: 1: I-Defrost (EKC 202A) noma Ukukhanya (EKC 202C) 2: I-alamu |

o72 | I-DO4 Config |

| – – – Ukubuyisela emuva Ebusuku 0=Usuku

1=Ubusuku |

| Isevisi | Isevisi | |

| Izinga lokushisa likalwe ngenzwa ye-S5 | u09 | Izinga lokushisa le-S5. |

| Isimo kokokufaka kwe-DI. ku/1=kuvaliwe | u10 | Isimo se-DI1 |

| Isimo sokusebenza ebusuku (kuvuliwe noma kuvaliwe) 1=ukusebenza kwasebusuku | u13 | I-Night Cond. |

| Funda inkomba yamanje yomthetho | u28 | Temp. ref. |

| * Isimo ku-relay yokupholisa | u58 | I-Comp1/LLSV |

| * Isimo sokudluliswa kwabalandeli | u59 | Ukudluliselwa kwabalandeli |

| * Isimo ku-relay yokuncibilika | u60 | Def. udlulise |

| * Izinga lokushisa likalwa ngenzwa ye-Sair | u69 | Sair temp |

| * Isimo ku-relay 4 (i-alamu, i-defrost noma umsebenzi okhanyayo) | u71 | Isimo se-DO4 |

| *) Akuzona zonke izinto ezizoboniswa. Umsebenzi wohlelo olukhethiwe kuphela ongabonwa. |

| Umlayezo wephutha | Ama-alamu | |

| Esimeni sephutha ama-LED angaphambili azokhanya futhi i-alamu edluliselwe izosebenza. Uma ucindezela inkinobho ephezulu kulesi simo ungabona umbiko we-alamu kusibonisi. Uma kukhona okunye push futhi ukuze ubabone.

Kunezinhlobo ezimbili zemibiko yamaphutha - kungaba i-alamu eyenzeka nsuku zonke, noma kube khona iphutha ekufakeni. Ama-alamu ngeke abonakale kuze kube yilapho ukubambezeleka kwesikhathi esimisiwe kuphelelwe yisikhathi. Ama-alamu e-E, ngakolunye uhlangothi, azobonakala lapho iphutha lenzeka. (I-alamu ngeke ibonakale inqobo nje uma kukhona i-alamu ka-E esebenzayo). Nansi imilayezo engavela: |

1 = i-alamu |

|

| I-A1: I-alamu yokushisa okuphezulu | Phezulu t. i-alamu | |

| A2: I-alamu yokushisa ephansi | Okuphansi t. i-alamu | |

| A4: I-alamu yomnyango | I-Alarm Yomnyango | |

| A5: Ulwazi. Ipharamitha engu-o16 iphelelwe yisikhathi | I-Max Hold Time | |

| A15: I-alamu. Isignali evela ku-DI input | I-alamu ye-DI1 | |

| I-A45: Indawo elindile (isiqandisi esimisiwe nge-r12 noma i-DI input) | Imodi yokulinda | |

| A59: Ukuhlanzwa kwecala. Isignali evela ku-DI input | Ukuhlanzwa kwecala | |

| I-A61: I-alamu ye-condenser | Cond. i-alamu | |

| E1: Amaphutha kusilawuli | Iphutha le-EKC | |

| I-E6: Iphutha ewashini lesikhathi sangempela. Hlola ibhethri / setha kabusha iwashi. | – | |

| I-E27: Iphutha lenzwa ku-S5 | Iphutha le-S5 | |

| E29: Iphutha lenzwa ku-Sair | Iphutha le-Sair | |

| Lapho ukopisha izilungiselelo uye noma usuka enkinobho yokukopisha enefuncns u-o65 noma u-o66, ulwazi olulandelayo lungase luvele:

0: Ukukopisha kuqediwe futhi KULUNGILE 4: Ukhiye wokukopisha awukhwezwanga kahle 5: Ukukopisha bekungalungile. Phinda ukukopisha okungu-6: Ukukopisha ku-EKC akulungile. Phinda ukukopisha 7: Ukukopishela kukhiye wokukopisha akulungile. Phinda ukukopisha 8: Ukukopisha akwenzeki. Inombolo ye-oda noma inguqulo ye-SW ayifani no-9: Iphutha lokuxhumana nesikhathi sokuvala 10: Ukukopisha kusaqhubeka (Ulwazi lungatholakala ku-o65 noma ku-o66 imizuzwana embalwa ngemva kokukopisha waqala). |

||

| Izindawo ze-alamu | ||

| Ukubaluleka kwama-alamu angawodwana kungachazwa ngesilungiselelo (0, 1, 2 noma 3) |

Isexwayiso! Ukuqala okuqondile kwama-compressor

Ukuze uvimbele amapharamitha wokuqhekeka kwe-compressor u-c01 no-c02 kufanele asethwe ngokuvumelana nezimfuneko zomphakeli o, r ngokuvamile, i-Hermetic Compressors c02 min. 5 amaminithi, Semihermetic Compressors c02 min. 8 amaminithi, kanye ne-c01 min. Imizuzu emi-2 ukuya kwemi-5 ( Injini esuka ku-5 ukuya ku-15 KW ) * ). Ukusebenza okuqondile kwama-valve e-solenoid akudingi izilungiselelo ezihlukile kufekthri (0).

Khipha

Isilawuli siqukethe inani lemisebenzi engasetshenziswa kanye nomsebenzi wokukhipha ku-master gateway / Isiphathi Sesistimu.

|

Umsebenzi ngokuxhumana kwedatha |

Imisebenzi ezosetshenziswa emasangweni khipha umsebenzi |

Ipharamitha esetshenziswa ku-EKC 202 |

| Ukuqala kwe-defrosting | Isikhathi sokulawula i-Defrost | – – – Def. qala |

| I-defrost ehlanganisiwe | Ukulawula i-Defrost |

– – – HoldAfterDef u60 Def.relay |

| Ukubuyela emuva ebusuku |

Ukulawula usuku/ubusuku Isheduli yesikhathi |

– – – Ukusetha ebusuku |

| Ukulawula ukukhanya | Ukulawula usuku/ubusuku Isheduli yesikhathi | o39 Isilawuli kude esikhanyayo |

Ukuxhumana

Ukunikezwa kwamandla kagesi

- 230 V ac

Izinzwa

- I-Sair iyinzwa ye-thermostat.

- I-S5 iyinzwa ye-defrost futhi isetshenziswa uma i-defrost kufanele imiswe ngokuya ngezinga lokushisa. Nokho, ingasetshenziswa futhi njengenzwa yomkhiqizo noma inzwa ye-condenser.

Isiginali yeDigital Vuliwe/Cishiwe

Okokufaka okusikiwe kuzovula umsebenzi. Imisebenzi engenzeka ichazwe kumenyu o02.

Ukudluliselwa

Izixhumanisi ezijwayelekile yilezi: Isiqandisi. Othintwayo uzongena lapho isilawuli sifuna i-Frige Defrost. Umlandeli.

- I-alamu. I-relay iyasikwa ngesikhathi sokusebenza okujwayelekile futhi inqamule ezimeni ze-alamu nalapho isilawuli sesifile (siphelelwa amandla)

- Ukukhanya. Oxhumana naye uzongena lapho isilawuli sifuna ukukhanya.

Umsindo kagesi

Amakhebuli ezinzwa, okokufaka kwe-DI, nokuxhumana kwedatha kufanele kugcinwe kuhlukene kwamanye amakhebuli kagesi:

- Sebenzisa amathreyi ekhebula ahlukene

- Gcina ibanga phakathi kwezintambo okungenani libe ngu-10 cm

- Izintambo ezinde kokokufaka kwe-DI kufanele zigwenywe

Ukuxhumana kwedatha

Uma ukuxhumana kwedatha kusetshenziswa, kubalulekile ukuthi ukufakwa kwekhebula lokuxhumana kwedatha kwenziwe ngendlela efanele. Bheka izincwadi ezihlukene No. RC8AC.

- MODBUS noma i-LON-RS485 ngokufaka amakhadi.

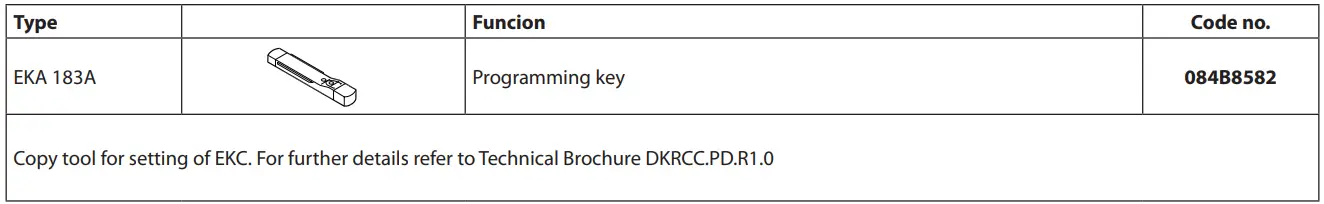

Iya-oda

- Izinzwa lokushisa: ngicela ubhekisele ku-lit. cha. I-RK0YG

Idatha yobuchwepheshe

| Ukunikezwa kwevoltage | 230 V ac +10/-15 %. 2.5 VA, 50/60 Hz | ||

| Izinzwa 3 ama-pcs noma | Pt 1000 noma

I-PTC 1000 noma I-NTC-M2020 (5000 ohm / 25°C) |

||

|

Ukunemba |

Ibanga lokulinganisa | -60 kuya +99°C | |

|

Isilawuli |

±1 K ngaphansi -35°C

±0.5 K phakathi -35 kuya +25°C ±1 K ngaphezu kuka +25°C |

||

| Pt 1000

inzwa |

±0.3 K ku-0°C

±0.005 K ngegredi ngayinye |

||

| Bonisa | I-LED, amadijithi angu-3 | ||

|

Okokufaka kwedijithali |

Isiginali evela kumisebenzi yokuxhumana Izimfuneko kothintana nabo: I-Gold plating, Ubude bekhebula kufanele bube bukhulu. 15 m

Sebenzisa ama-relay asizayo uma ikhebuli iyinde |

||

| Ikhebuli yokuxhuma kagesi | Ubukhulu.1,5 mm2 ikhebula le-multi-core

Ubukhulu. 1 mm2 kuzinzwa nokokufaka kwe-DI |

||

|

Ukudluliselwa* |

IEC60730 | ||

| EKC 202

|

DO1 | 8 (6) A & (5 FLA, 30 LRA) | |

| DO2 | 8 (6) A & (5 FLA, 30 LRA) | ||

| DO3 | 6 (3) A & (3 FLA, 18 LRA) | ||

| DO4** | 4 (1) A, Min. 100 mA** | ||

| Ukuxhumana kwedatha | Ngekhadi lokufaka | ||

|

Imvelo |

0 kuya +55°C, Ngesikhathi sokusebenza

-40 kuya +70°C, Ngesikhathi sokuthutha |

||

| I-20 - 80% Rh, ayifinyeziwe | |||

| Akukho thonya lokushaqeka/ukudlidliza | |||

| Indawo ebiyelwe | IP65 ukusuka ngaphambili.

Izinkinobho nokupakisha kushumekwe ngaphambili. |

||

| Indawo yokubalekela iwashi |

4 amahora |

||

|

Izimvume |

I-EU Low VoltagI-e Directive kanye ne-EMC ifuna ukuthi ukumakwa kabusha kwe-CE kuthotshelwe

I-EKC 202: I-UL yokugunyaza i-acc. I-UL 60730 I-LVD ihlolwe i-acc. I-EN 60730-1 kanye ne-EN 60730-2-9, A1, A2 I-EMC ihlolwe i-acc. I-EN 61000-6-3 kanye ne-EN 61000-6-2 |

||

- I-DO1 kanye ne-DO2 ziyi-16 A ama-relay. I-8 A eshiwo inganyuswa ifike ku-10 A, lapho izinga lokushisa lendawo ligcinwa lingaphansi kuka-50°C. I-DO3 ne-DO4 ziyi-8A edluliselwe. Ngaphezulu kwe-max. Umthwalo kufanele ugcinwe.

- Ukufakwa kwegolide kuqinisekisa umsebenzi omuhle ngemithwalo encane yokuxhumana

U-Danfoss akakwazi ukwamukela isibopho ngamaphutha angaba khona kumakhathalogi, izincwajana, nokunye okuphrintiwe. I-Danfoss igodla ilungelo lokushintsha imikhiqizo yayo ngaphandle kwesaziso. Lokhu kusebenza futhi emikhiqizweni esivele ine-oda inqobo nje uma lokho kushintshwa kungenziwa ngaphandle kokuba kube noshintsho oludingekayo emibhalweni osekuvunyelwene ngayo. Zonke izimpawu zokuhweba kule nto ziyimpahla yezinkampani ezifanele. I-Danfoss ne-Danfoss logotype yizimpawu zokuthengisa ze-Danfoss A/S. Wonke Amalungelo Agodliwe.

imibuzo ejwayelekile ukubuzwa

Ngiwuqala kanjani umjikelezo we-defrost?

Umjikelezo we-defrost ungaqalwa ngezindlela ezahlukahlukene, okubandakanya isikhawu, isikhathi sesiqandisi, isignali yokuxhumana, ukwenza kusebenze mathupha, uhlelo, noma ukuxhumana kwenethiwekhi.

I-digital input ingasetshenziselwa ini?

Okokufaka kwedijithali kungasetshenziselwa imisebenzi efana nokuthinta umnyango ngesaziso se-alamu uma umnyango uhlala uvuliwe.

Amadokhumenti / Izinsiza

|

I-Danfoss EKC 202A Isilawuli Sokulawula Izinga lokushisa [pdf] Umhlahlandlela Womsebenzisi 202A, 202B, 202C, EKC 202A Controller For Temperature Control, EKC 202A, Controller For Temperature Control, For Temperature Control, Temperature Control |