I-Danfoss AK-CC 210B Isilawuli Sokulawula Izinga lokushisa

Ulwazi Lomkhiqizo

Imininingwane

- Imodeli: AK-CC 210B

- Inguqulo Yesofthiwe: SW 1.0x

- Isicelo: Plug-in amakhabethe ezitolo ezinkulu

- Ukudlulisa: 4 ukudluliselwa kwesiqandisi, i-Defrost, ukukhanya, kanye nohlelo lokusebenza olukhethwe umsebenzisi

Imiyalo yokusetshenziswa komkhiqizo

- Ukuze uthole imininingwane yoku-oda, sicela ubheke imanuwali yomsebenzisi.

- Isilawuli singaxhunywa kuzinzwa namadivayisi ngokwemiyalo enikezwe kumanuwali yomsebenzisi.

- Idatha ehlobene nokunemba, izinhlobo zezinzwa, nezinhlelo zokusebenza ichazwe kumanuwali.

Isingeniso

Isicelo

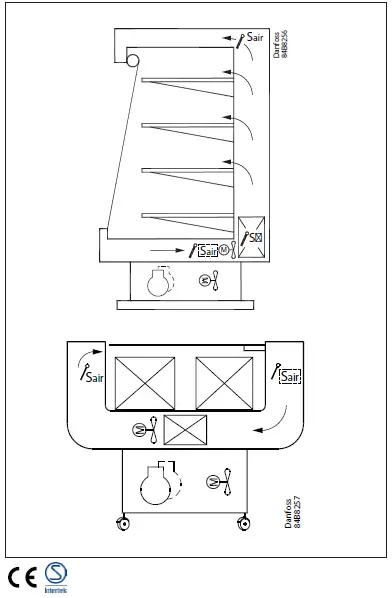

- I-AK-CC 210B inikezelwe “kumakhabethe afakiwe” ezitolo ezinkulu.

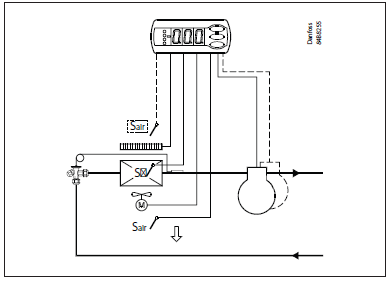

Isimiso

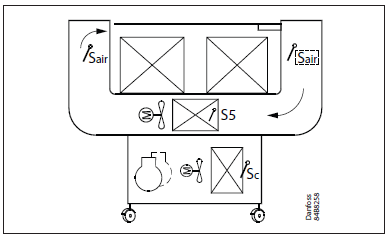

- I-AK-CC 210B ilawula izinga lokushisa ekhabetheni ngokusekelwe esilinganisweni esivela kunzwa eyodwa - i-Sair.

- Le nzwa ingafakwa ekugelezeni komoya okubandayo ngemva kwe-evaporator noma ekugelezeni komoya okufudumele ngaphambi kwe-evaporator, kuye ngokwakhiwa nokusetshenziswa kwekhabhinethi.

- Isilinganiso sokushisa kwe-defrost singatholwa ngokuqondile ngokusebenzisa inzwa ye-S5 noma ngokungaqondile ngokusebenzisa isilinganiso se-Sair.

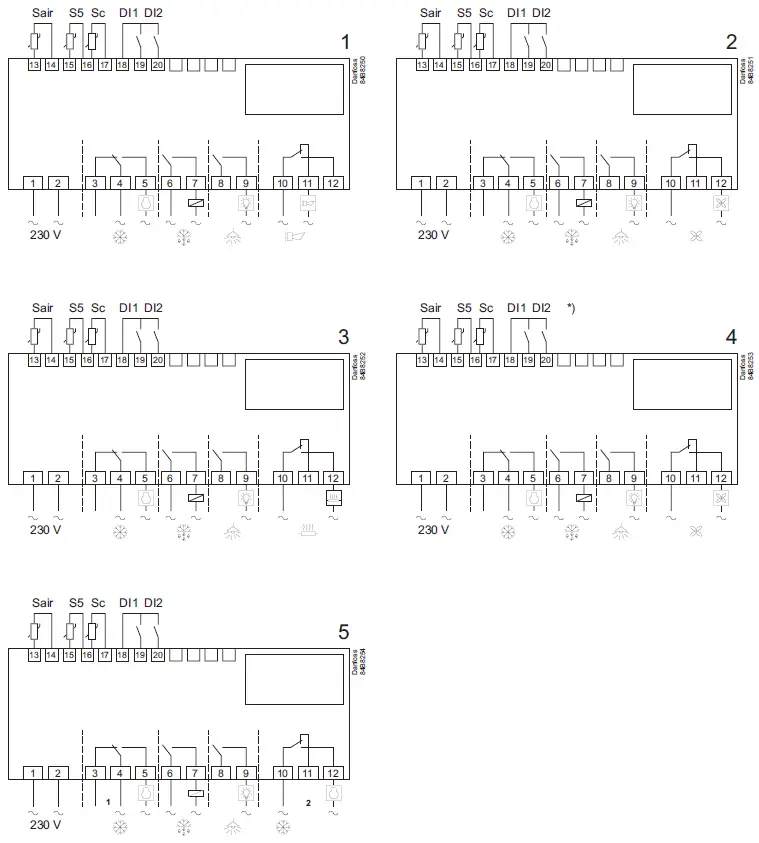

- Ama-Relays: ama-relay amathathu okuqala anikezelwe ku-Refrigeration, Defrost, kanye nokukhanya, ngokulandelana. Ukusetshenziswa kwe-relay 3 kukhethwa isilungiselelo sohlelo lokusebenza, futhi kungaba i-Alamu, iFani, ukushisa kukaloliwe, ifeni ye-Condenser noma i-Compressor 4.

- Izicelo ezahlukene ziyachazwa

I-Advantages

- Izinhlelo zokusebenza eziningi kuyunithi efanayo

- Isilawuli sinemisebenzi edidiyelwe yesiqandisi-zobuchwepheshe, ukuze singene esikhundleni salo lonke iqoqo lama-thermostats nezibali sikhathi.

- Izinkinobho nophawu kufakwe ngaphambili

- Ukuqapha kwe-alamu kwezinga lokushisa le-condenser elinokuvikelwa kokumiswa kwe-compressor.

- Ama-relay avaliwe ukuze asetshenziswe neziqandisi ezingama-R290

- Ingakwazi ukulawula ama-compressor amabili

- Kulula ukukhweza ukuxhumana kwedatha

- Ukusetha okusheshayo

- Izinkomba zokushisa ezimbili

- Okokufaka kwedijithali kwemisebenzi ehlukahlukene

- Umsebenzi wewashi one-super-cap backup

- Ukulinganisa kwasefekthri okuzoqinisekisa ukunemba okungcono kokulinganisa kunalokho okushiwo ku-EN ISO 23953-2 ejwayelekile ngaphandle kokulinganisa okulandelayo (inzwa ye-Pt 1000 ohm)

Ukusebenza

Ukusebenza - Izinzwa

- Inzwa eyodwa ye-thermostat - i-Sair - ingaxhunywa kusilawuli, futhi isicelo esifanelekile sichaza ukubekwa.

- Ingafakwa emoyeni ngaphambi kwe-evaporator noma ekugelezeni komoya ngemva kwe-evaporator. Lesi sakamuva sisetshenziswa ikakhulukazi lapho kunengozi yokushisa okuphansi kakhulu emikhiqizweni.

Inzwa ye-Defrost

- Isignali engcono kakhulu ephathelene nezinga lokushisa le-evaporator itholakala kunzwa yokuncibilikisa efakwe ngqo ku-evaporator.

- Lapha isignali ingase isetshenziswe umsebenzi we-defrost, ukuze i-defrost emfushane futhi eyonga amandla kakhulu ingenzeka.

- Uma ingadingeki inzwa ye-defrost, i-defrost ingamiswa ngokusekelwe ngesikhathi, noma i-Sair ingakhethwa.

Inzwa yokushisa ye-Condenser

- Inzwa yokushisa ye-condenser - Sc - ingasetshenziselwa ukuqapha izinga lokushisa ku-condenser.

- Kuye ngezilungiselelo, ama-alamu angenziwa futhi ezinye izenzo, kuhlanganise nokumisa ukuphepha kwe-compressor, zingaqaliswa ngokusekelwe kulokhu kushisa.

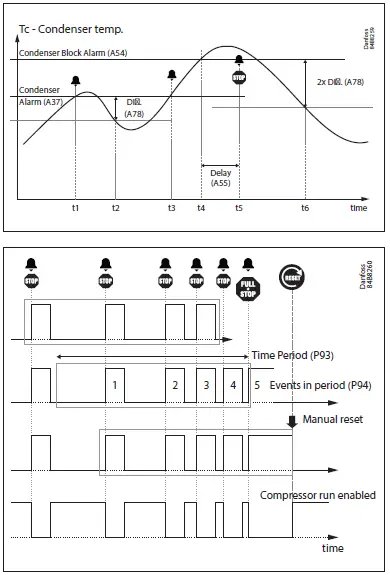

Ama-alamu okushisa e-Condenser nezenzo

- Isexwayiso se-alamu singenziwa sisebenze lapho izinga lokushisa lifika ngaphezu kwesethi yomkhawulo we-Alarm ye-Condenser futhi i-alamu ebalulekile ingavulwa ngomkhawulo ophezulu we-Alarm Block Condenser.

- Kuleli zinga elibucayi, izenzo ezehlukene zingaqalwa isb, ukucisha ukukhanya kukhabhinethi, ukucisha i-compressor, noma kokubili. Isenzo esifunwayo sichazwa yipharamitha "P92".

- Ama-compressor angamiswa unomphela uma inombolo echaziwe yama-alamu abalulekile enzeka phakathi nesikhathi esinqunyiwe. Uma inani lezehlakalo lidlula ukulungiselelwa kwepharamitha “P94” phakathi nesikhathi esichazwe ku-“P93”, umcimbi wokugcina uyohlale uhlanganisa isitobhi se-compressor, kanye nezinye izenzo ezichazwe ku-“P92”.

- Lesi simo sidinga ukusetha kabusha ngesandla ngaphambi kokuthi i-compressor iqale futhi.

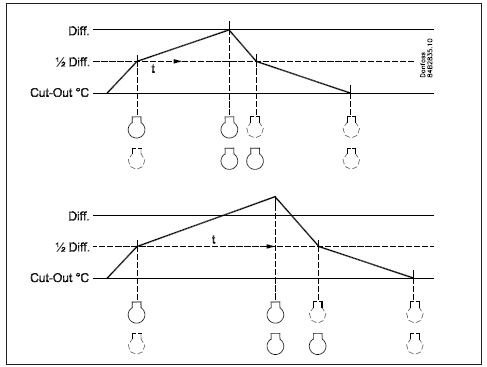

Ukulawula ama-compressor amabili

- Lokhu kulawulwa kusetshenziselwa ukulawula ama-compressor amabili anosayizi ofanayo. Umgomo wokulawula ukuthi enye yama-compressor ixhuma ku-½ umehluko we-thermostat, kanti enye kumehluko ogcwele. Lapho i-thermostat ingena, i-compressor enamahora ambalwa okusebenza iyaqalwa. Enye i-compressor izoqala kuphela ngemva kokubambezeleka kwesikhathi esimisiwe, ukuze umthwalo uzohlukaniswa phakathi kwabo. Ukubambezeleka kwesikhathi kunokubaluleka okuphezulu kunezinga lokushisa.

- Lapho izinga lokushisa lomoya lehlile ngesigamu sokuhluka, enye ye-compressor izoyeka, kuyilapho enye izoqhubeka nokusebenza futhi ingayeki kuze kube yilapho izinga lokushisa elidingekayo lifinyelelwa.

- Ama-compressor asetshenzisiwe kufanele abe uhlobo olukwazi ukuqala ngokumelene nokucindezela okukhulu.

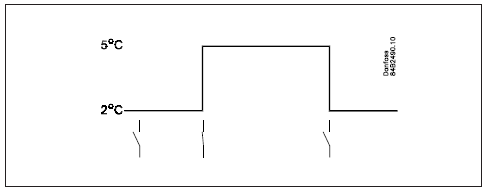

Ukushintsha kwereferensi yezinga lokushisa

- Entweni esetshenziswa ngokungaguquki, ngokwesiboneloampi-le, esetshenziselwa amaqembu emikhiqizo ehlukahlukene inkomba yezinga lokushisa ishintshwa kalula ngesignali yokuxhumana kokokufaka kwedijithali.

- Isiginali ishintsha indawo yokubeka ye-thermostat evamile ngevelu echazwe ngaphambilini. Ngesikhathi esifanayo, imikhawulo ye-alamu ephezulu nephansi izosethwa ngenani elifanayo.

Ukubuyela emuva ebusuku

- Ireferensi ye-thermostat ingaboniswa nge-offset ebusuku.

- Inani lomkhawulo we-alamu lizoshintshwa libe yinani elifanayo njenge-offset yasebusuku. Ushintsho luzosetshenziswa kuphela ku-offset yasebusuku enhle.

Okokufaka kwedijithali

Kukhona okokufaka kwedijithali okubili, kokubili okungasetshenziselwa imisebenzi elandelayo:

- Ukuhlanzwa kwecala

- Umsebenzi wokuxhumana nomnyango nge-alamu

- Ukuqala i-defrost

- I-Coordinated defrost (DO2 kuphela)

- Ukubuyela emuva ebusuku

- Ukushintsha phakathi kwezithenjwa zezinga lokushisa ezimbili

- Bika isimo sokufakwayo kwedijithali ngokuxhumana kwedatha

Umsebenzi wokuhlanza ikesi

- Lo msebenzi wenza kube lula ukuqondisa into esebenza esiqandisini ngesigaba sokuhlanza.

- Ngokucindezela okuthathu kuswishi, ushintsha usuka kwesinye isigaba uye kwesinye.

- Ukucindezela kokuqala kumisa isiqandisi - abalandeli bayaqhubeka nokusebenza.

- "Kamuva": Ukuphusha okulandelayo kumisa abalandeli

- "Kuseza kamuva": Ukucindezela okulandelayo kuqalisa kabusha isiqandisi

- Izimo ezahlukene zingalandelwa esibukweni.

- Kunethiwekhi, i-alamu yokuhlanza idluliselwa kuyunithi yesistimu.

- Le alamu "ingafakwa" ukuze kunikezwe ubufakazi bokulandelana kwemicimbi.

Umsebenzi wokuxhumana nomnyango

- Emakamelweni abandayo nasemagumbini ayisithwathwa, iswishi yomnyango ingakhanyisa futhi ivale isibani, iqale futhi imise isiqandisi futhi inikeze i-alamu uma umnyango uhlale uvulekile isikhathi eside kakhulu.

I-Defrost

- Ngokuya ngohlelo lokusebenza, ungakhetha phakathi kwalezi zindlela zokuncibilika ezilandelayo:

- Imvelo: Lapha, abalandeli bagcinwa besebenza ngesikhathi sokumiswa kweqhwa

- Ugesi: Isici sokushisisa siyasebenza

- Igesi eshisayo: I-defrost ephumayo isetshenziselwa ukulawula i-solenoid evumela igesi eshisayo ukuthi igeleze ku-evaporator. I-compressor igcinwa isebenza ukuze ikhiqize igesi eshisayo.

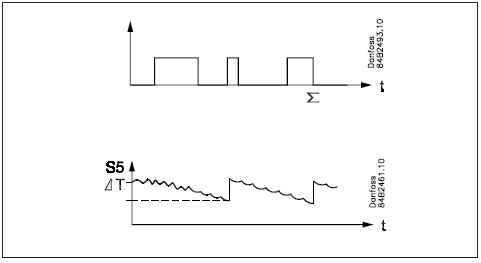

Ukuqala kwe-defrost

- I-defrost ingaqalwa ngezindlela ezahlukahlukene:

- Isikhawu: I-Defrost iqalwa ngezikhathi ezimisiwe, isb njalo ngehora lesishiyagalombili

- Isikhathi sokuqandisa: I-Defrost iqala ngezikhathi ezithile zesiqandisi. Ngamanye amazwi, isidingo esiphansi sesiqandisi "sizokuhlehlisa" ukuchithwa kweqhwa okuzayo.

- Isheduli: Lapha i-defrost ingaqalwa ngezikhathi ezimisiwe zemini nobusuku. Nokho, max. 6 izikhathi.

- Othintana naye: I-Defrost iqalwa ngesignali yokuxhumana kokokufaka kwedijithali.

- Inethiwekhi: Isiginali yokuncibilika itholwa kuyunithi yesistimu ngokuxhumana kwedatha.

- I-S5 temp Kumasistimu angu-1:1 ukusebenza kahle kwe-evaporator kungalandelwa. I-icing-up izoqala ukuncibilika.

- Imanuwali: I-defrost eyengeziwe ingenziwa isebenze kusukela enkinobho ephansi yesilawuli.

- (Nakuba kungenjalo isicelo 4).

Zonke izindlela ezishiwo zingasetshenziswa ngokungahleliwe - uma eyodwa yazo icushiwe kuzoqalwa i-defrost.

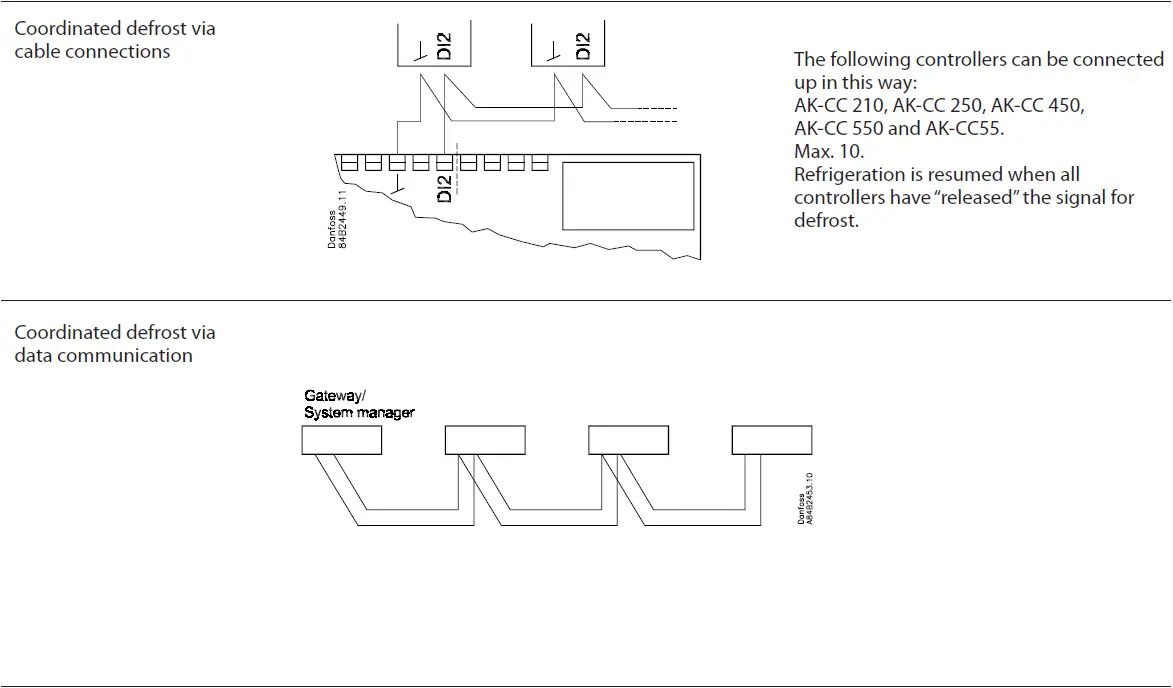

I-defrost ehlanganisiwe

- Kunezindlela ezimbili lapho i-defrost ehlanganisiwe ingahlelwa.

- Kungaba ngoxhumo lwezintambo phakathi kwezilawuli noma ngokuxhumana kwedatha.

Ukuxhumeka kwentambo

- Esinye sezilawuli sichazwa njengeyunithi yokulawula futhi imojula yebhethri ingase ifakwe kuyo ukuze iwashi liqiniseke ukuthi liyagcinwa. Lapho i-defrost iqalisiwe, zonke ezinye izilawuli zizolandela okufanayo futhi ngokufanayo ziqale ukumisa uqhwa. Ngemva kokuncibilika, izilawuli ngazinye zizohamba ziye endaweni yokulinda. Lapho bonke sebemi endaweni yokulinda, kuzoba nokushintshela esiqandisini.

- (Uma oyedwa eqenjini efuna ukuncibilika, abanye bazolandela okufanayo).

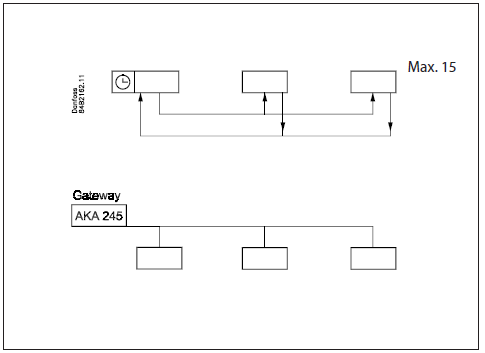

Defrost ngokusebenzisa ukuxhumana kwedatha

- Zonke izilawuli zifakwe imojula yokuxhumana kwedatha, futhi ngomsebenzi wokukhipha ovela esangweni, i-defrost ingahlanganiswa.

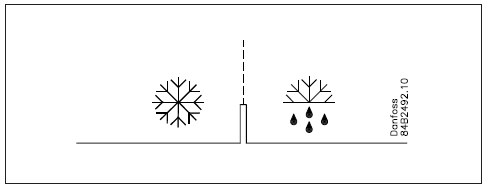

Defrost uma kudingeka

- Ngokusekelwe esikhathini sesiqandisi

Uma isikhathi sesiqandisi esihlanganisiwe sesidlulile isikhathi esimisiwe, i-defrost izoqala. - Ngokusekelwe ezingeni lokushisa

Isilawuli sizohlala silandela izinga lokushisa ku-S5.

Phakathi kwama-defrosts amabili, izinga lokushisa le-S5 lizoba phansi kakhulu lapho i-evaporator ikhuphuka kakhulu (i-compressor isebenza isikhathi eside futhi idonsa izinga lokushisa le-S5 liye phansi). Uma izinga lokushisa lidlula isethi ehlukile evunyelwe, i-defrost izoqalwa.

Lo msebenzi ungasebenza kuphela kumasistimu we-1:1.

I-alamu yesicelo sesevisi

- Isilawuli sizobhalisa okunqwabelene ngesikhathi ngezinsuku, futhi umkhawulo ungasethwa ukuze uvule "i-alamu yesicelo sesevisi" ukukhombisa ukuthi ukuhlolwa nokuhlanzwa kwefeni ne-condenser kuseduze.

- Ngemva kokwenza kanjalo, isibali se-Runtime singasethwa kabusha futhi kuqaliswe isikhathi esisha.

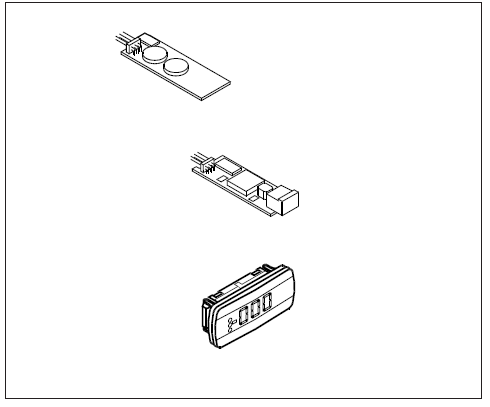

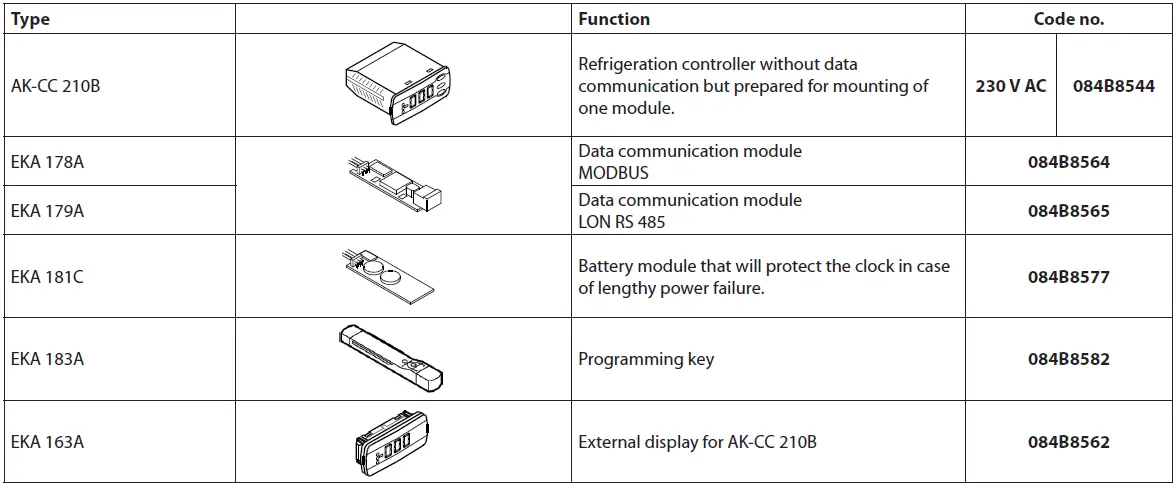

Imojula eyengeziwe

- Ngemva kwalokho isilawuli singafakwa imojuli yokufaka uma uhlelo lokusebenza luyidinga.

- Isilawuli silungiswe ngepulaki, ngakho-ke imojula kufanele iphushwe nje.

- Imodyuli yebhethri

- Imojula iqinisekisa ivolumutage kusilawuli uma umthamo wokunikezelatage yeka isikhathi esingaphezu kwamahora amane. Ngakho-ke umsebenzi wewashi ungavikelwa ngesikhathi sokuhluleka kwamandla.

- Ukuxhumana kwedatha

- Uma udinga ukusebenza kwi-PC, imojula yokuxhumana kwedatha kufanele ibekwe kusilawuli.

Isibonisi sangaphandle

- Uma kudingekile ukukhombisa izinga lokushisa ngaphambi komshini wesiqandisi, uhlobo lokubonisa i-EKA 163A lungafakwa.

- Isibonisi esengeziwe sizobonisa ulwazi olufanayo nesibonisi sesilawuli, kodwa asibandakanyi izinkinobho zokusebenza. Uma ukusebenza okuvela kusibonisi sangaphandle kudingekile uhlobo lokubonisa i-EKA 164A kufanele lufakwe.

Izinhlelo zokusebenza

I-AK-CC 210B yenzelwe amakhabethe epulaki afakwe esiqandisini ane-compressor eyodwa noma amabili.

3 izinzwa zingaxhunywa: Sair, S5 (Defrost termination), kanye Sc (Condenser lokushisa).

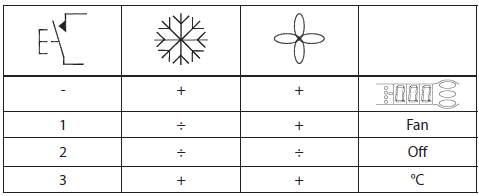

Ama-relay amathathu okuqala asetshenziselwa i-compressor on-off, defrost, kanye nokukhanya, kuyilapho i-relay 3 ilungiseka nge-"o4" yohlelo lokusebenza. I-relay ingalungiselelwa izinhlelo zokusebenza ezi-61 ezahlukene:

- I-alamu edluliselwe

- Ukulawulwa kwefeni ye-Evaporator

- Ukulawula Ukushisa Kwesitimela

- Ukulawula abalandeli be-Condenser

- Isilawuli se-compressor sesibili

I-DI1, ne-DI2 kukhona okokufaka kwe-Dry Contact okuguquguqukayo okungalungiselelwa imisebenzi eminingi nge-“o02” noma “o37”

Izixhumanisi ezincike kuhlelo lokusebenza

Inhlolovo yemisebenzi

| Umsebenzi | Ipharamitha | Ipharamitha ngokusebenza ngedatha ukuxhumana |

| Okuvamile isibonisi | ||

| Ngokuvamile, inani lokushisa elivela kunzwa ye-thermostat i-Sair liyaboniswa. | Bonisa umoya (u56) | |

| I-Thermostat | I-Thermostat ukulawula | |

| I-Setpoint

Umthethonqubo usekelwe kunani elimisiwe kanye nokusuka endaweni, uma kusebenza. Inani lisethwa ngokucindezela inkinobho ephakathi. Inani elimisiwe lingakhiywa noma likhawulelwe kububanzi ngezilungiselelo eziku-r02 no-r03. Ireferensi nganoma yisiphi isikhathi ingabonwa kokuthi ”u28 Temp. ref”. |

Ukusika °C | |

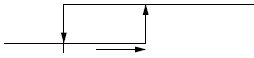

| Umehluko

Uma izinga lokushisa liphakeme kunereferensi + umehluko omisiwe, i-compressor relay izosikwa phakathi. Izonqamuka futhi lapho izinga lokushisa lehla kunkomba emisiwe. |

r01 | Umehluko |

| I-Setpoint umkhawulo Ref. I-Dif.

Ibanga lesilungiselelo sesilawuli sephoyinti lokusetha lingase lincishiswe kakhulu amanani aphezulu kakhulu noma aphansi kakhulu awasethwa ngephutha, nomphumela wokulimala. |

||

| Ukuze ugweme ukusetha okuphezulu kakhulu kwe-setpoint, umkhawulo. Inani lereferensi elivumelekile kufanele lehliswe. | r02 | Ukusika okuphezulu °C |

| Ukuze ugweme ukulungiselelwa okuphansi kakhulu kwe-setpoint, ubuncane. Inani lereferensi elivumelekile kufanele lenyuswe. | r03 | Ukusika okuncane °C |

| Ukulungisa of i isibonisi izinga lokushisa ekhombisa

Uma izinga lokushisa lemikhiqizo kanye nezinga lokushisa elitholwe isilawuli akufani, ukulungiswa kwe-offset kwezinga lokushisa lokubonisa kungenziwa. |

r04 | I-Disp. I-Adj. K |

| Izinga lokushisa iyunithi

Lapha usetha ukuthi isibonisi sesilawuli esokubonisa amanani okushisa ku-°C noma ku-°F. |

r05 | Temp. iyunithi

°C=0. / °F=1 |

| Ukulungiswa kwesiginali evela ku-Sair

Ukunxeshezelwa okungenzeka ngekhebula lenzwa ende |

r09 | Lungisa i-Sair |

| Qala / stop of esiqandisini

Ngalesi silungiselelo, isiqandisi singaqalwa, simiswe, noma ukukhipha mathupha kokuphumayo kungavunyelwa. Ukuqala / ukumiswa kwesiqandisi nakho kungafezwa ngomsebenzi wokushintsha wangaphandle oxhunywe kokokufaka kwe-DI. Isiqandisi esimisiwe sizonikeza "i-alamu yokulinda". |

r12 | Ukushintsha Okuyinhloko

1: Qala 0: Yima -1: Ukulawula okwenziwa ngesandla kokuphumayo kuvunyelwe |

| Ebusuku ukuhlehla inani

Ireferensi ye-thermostat izoba i-setpoint kanye nalelivelu lapho isilawuli sishintsha sisebenza ebusuku. (Khetha inani elingalungile uma kuzoba nokuqongelela okubandayo.) |

r13 | I-offset yasebusuku |

| Ukwenza kusebenze of ireferensi ukufuduka

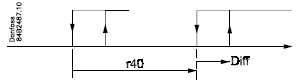

Uma umsebenzi ushintshelwa ku-ON, ireferensi ye-thermostat izokhishwa ivelu elingu-r40. Ukuqalisa kungase futhi kwenzeke ngokufaka i-DI1 noma i-DI2 (echazwe ngo-o02 noma o37). |

r39 | Th. offset |

| Inani of ireferensi ukufuduka

Ireferensi ye-thermostat namanani e-alamu ashintshwa ngenombolo elandelayo yamadigri lapho ukususwa kwenziwa kusebenze. Ukusebenza kungenziwa nge-r39 noma nge-put DI |

r40 | Th. susa K |

| Ukubuyisela emuva ebusuku (ukuqala kwesiginali yasebusuku) | ||

| Kuphole ngempoqo. (ukuqala kokupholisa ngempoqo) |

| I-alamu | Izilungiselelo ze-alamu | |

| Isilawuli singanikeza i-alamu ezimeni ezihlukene. Uma kune-alamu, wonke ama-light-emitting diode (ama-LED) azokhanyisa kuphaneli yangaphambili yesilawuli, futhi i-alamu edluliselwe izongena phakathi. | Ngokuxhumana kwedatha, ukubaluleka kwama-alamu ngamanye kungachazwa. Ukusetha kwenziwa kumenyu "yezindawo ze-alamu". | |

| I-alamu ukubambezela (ukubambezeleka kwe-alamu okufushane)

Uma eyodwa kwamanani amabili omkhawulo yeqiwe, umsebenzi wesibali sikhathi uzoqala. I-alamu ngeke isebenze kuze kudlule ukulibaziseka kwesikhathi esimisiwe. Ukubambezeleka kwesikhathi kusethwe ngamaminithi. |

A03 | Ukubambezeleka kwe-alamu |

| Ukubambezeleka kwesikhathi kwe-alamu yomnyango

Ukubambezeleka kwesikhathi kusethwe ngamaminithi. Umsebenzi uchazwa ku-o02 noma o37. |

A04 | I-DoorOpen del |

| Ukulibaziseka kwesikhathi sokupholisa (ukubambezeleka okude kwe-alamu)

Lesi sikhathi sokulibaziseka sisetshenziswa ngesikhathi sokuqala, ngesikhathi sokumiswa kweqhwa futhi ngokushesha ngemva kokumiswa kweqhwa. Kuzoba noshintsho ekubambezelekeni kwesikhathi esijwayelekile (A03) uma izinga lokushisa lehlile ngaphansi komkhawulo we-alamu omisiwe. Ukubambezeleka kwesikhathi kusethwe ngamaminithi. |

A12 | Donsela phansi del |

| Umkhawulo we-alamu ophezulu

Lapha usetha umkhawulo we-alamu we-alamu yezinga lokushisa eliphezulu. Umkhawulo usethwe ngo-°C (inani eliphelele). Phakathi nezimo zasebusuku, inani lomkhawulo lizoshintshwa libe inani elifanayo njenge-offset yasebusuku. Ushintsho luzosetshenziswa kuphela ku-offset yasebusuku enhle. Inani elilinganiselwe lizophinde lishintshwe mayelana nokugudluzwa kwereferensi u-r39. Noma ngabe lokhu kuhle noma kubi. |

A13 | I-HighLim Air |

| Phansi i-alamu umkhawulo

Lapha, usetha umkhawulo we-alamu wama-alamu okushisa okuphansi. Inani eliwumkhawulo lisethwe ku-°C (inani eliphelele). Phakathi nezimo zasebusuku, umkhawulo uzohlala ungashintshiwe, kuyilapho ireferensi ukususwa kuka-r39 kuzokwenyuka noma kwehlise umkhawulo ngenani elinikezwe ngo-r40. |

A14 | I-LowLim Air |

| Ukubambezeleka kwe-alamu ye-DI1

Okokufaka kokusika/okusika kuzoholela ku-alamu lapho ukubambezeleka kwesikhathi sekudlulile. Umsebenzi uchazwa ku-o02. |

A27 | I-AI.Libazisa i-DI1 |

| Ukubambezeleka kwe-alamu ye-DI2

Okokufaka kokusika/okusika kuzoholela ku-alamu lapho ukubambezeleka kwesikhathi sekudlulile. Umsebenzi uchazwa ku-o37 |

A28 | I-AI.Libazisa i-DI2 |

| Umkhawulo we-alamu ye-Condenser

I-Setpoint ye-alamu yezinga lokushisa le-condenser, izinga lesexwayiso ngaphandle kokuma kwe-compressor. I-alamu izosula uma izinga lokushisa le-condenser lehliswa linani elichazwe kupharamitha A78. |

A37 | Cond Al.Lim |

| Umkhawulo we-alamu ye-Condenser block

Isethi ye-alamu ye-condenser block. Ukusebenzisa le alamu kungase kuqalise isenzo - Cisha ukukhanya, i-compressor stop, noma kokubili (bona ipharamitha P92) I-alamu izosula uma izinga lokushisa le-condenser lehliswa izikhathi ezingu-2 inani elichazwe kupharamitha A78. |

A54 | Cond T. Block |

| Ukubambezeleka kwe-alamu ye-Condenser

Ukubambezeleka kwe-alamu ye-condenser block kanye nesenzo esingaba khona. Ukubambezeleka kuqala lapho izinga lokushisa le-condenser lidlula umkhawulo kupharamitha A54. |

A55 | Al.Del.. Cond |

| Umehluko we-alamu ye-Condenser

Ibhendi yomehluko engaphansi kwezilungiselelo zokushisa kwe-alamu ye-condenser (A37 ne-A54) yokusula ama-alamu. |

A78 | Cond Al.Diff |

| Setha kabusha i-alamu | ||

| Iphutha le-EKC |

| I-Compressor | I-Compressor ukulawula | |

| I-compressor relay isebenza ngokubambisana ne-thermostat. Uma i-thermostat idinga isiqandisi, i-compressor relay izosebenza. | ||

| Izikhathi zokugijima

Ukuze uvimbele ukusebenza ngendlela engafanele, amanani angasethwa ngesikhathi okufanele i-compressor isebenze uma isiqalile, nokuthi kufanele imiswe isikhathi esingakanani. Izikhathi zokusebenza azibonwa lapho ama-defrosts eqala. |

||

| Okuncane. NGESIKHATHI (ngemizuzu) | c01 | Okuncane. Ngesikhathi |

| Okuncane. ISIKHATHI SOKUVAMILE (ngamaminithi) | c02 | Okuncane. Isikhathi sokuphumula |

| Ukulibaziseka kwesikhathi sokuhlanganisa ama-compressor amabili

Izilungiselelo zibonisa isikhathi okufanele sidlule kusukela ekusikelweni kokudlulisela phambili futhi kuze kube yilapho i-relay elandelayo kufanele ingene. |

c05 | Ukubambezeleka kwesinyathelo |

| I-LED engaphambili kwesilawuli izobonisa ukuthi isiqandisi siyaqhubeka yini. | I-Compa Relay

Lapha ungafunda isimo se-compressor relay, noma ungaphoqa ukulawula ukudluliswa kwemali ku-”Manual. control” mode |

|

| I-Defrost | I-Defrost ukulawula | |

| Isilawuli siqukethe umsebenzi wesikhathi osethwa kabusha ngemva kokuqala ngakunye kwe-defrost. Umsebenzi we-timer uzoqala ukuncibilika uma/uma isikhathi sokuphumula sesidlulile.

Umsebenzi wesibali sikhathi uqala lapho ivolumutagU-e uxhumeke kusilawuli, kodwa uyakhutshazwa okokuqala ngqa ngokulungiselelwa kokuthi d05. Uma kukhona ukuhluleka kwamandla, inani lesibali sikhathi lizogcinwa futhi lizoqhubeka ukusuka lapha lapho amandla ebuya. Lokhu kusebenza kwe-timer kungasetshenziswa njengendlela elula yokuqala ukuncibilika, kodwa kuzohlala kusebenza njengokuncibilika kokuphepha uma okunye kokuncishiswa kweqhwa okulandelayo kungatholwa. Isilawuli siqukethe newashi lesikhathi sangempela. Ngokusebenzisa izilungiselelo zaleli washi nezikhathi zezikhathi ezidingekayo zokuqeda isithwathwa, ukumiswa kweqhwa kungaqalwa ngezikhathi ezimisiwe zosuku. Uma kunobungozi bokungaphumeleli kwamandla izikhathi ezingaphezu kwamahora amane, imojuli yebhethri kufanele ifakwe kusilawuli. Ukuqala kwe-Defrost nakho kungenziwa ngokuxhumana kwedatha, ngamasiginali othintana naye, noma ukuqalisa mathupha. Zonke izindlela zokuqalisa zizosebenza kusilawuli. Imisebenzi ehlukene kufanele isethwe ukuze ama-defrost "angafiki edilika" ngokulandelana. I-Defrost ingenziwa ngogesi noma igesi eshisayo. I-defrost yangempela izomiswa ngokusekelwe esikhathini noma izinga lokushisa ngesignali evela ku-a inzwa yokushisa. |

||

| I-Defrost indlela

Lapha ubeka ukuthi i-defrost izofezwa ngogesi, igesi, noma "okungewona". Ngesikhathi se-defrost, i-defrost relay izonqunywa. |

d01 | Def. indlela 0 = non

1 = El 2 = Igesi |

| Defrost stop lokushisa

I-defrost imiswa ezingeni lokushisa elinikeziwe elilinganiswa ngenzwa (inzwa ichazwa ku-d10). Inani lokushisa lisethiwe. |

d02 | Def. Misa iTemp |

| Isikhawu phakathi kokuqala kwe-defrost

Umsebenzi unguziroset futhi uzoqala umsebenzi wesikhathi ekuqalweni ngakunye kwe-defrost. Uma isikhathi sesiphelile umsebenzi uzoqala ukuncibilika. Umsebenzi usetshenziswa njengesiqalo esilula sokuncibilika, noma ungasetshenziswa njengesivikelo uma isignali evamile yehluleka ukuvela. Uma kusetshenziswa i-master/slave defrost ngaphandle komsebenzi wewashi noma ngaphandle kokuxhumana kwedatha, isikhathi sokuphumula sizosetshenziswa njengobukhulu. isikhathi phakathi kwama-defrosts. Uma isiqalo sokuncibilika ngokuxhumana kwedatha singenzeki, isikhathi sokuphumula sizosetshenziswa njengobuningi. isikhathi phakathi kwama-defrosts. Uma kukhona ukuncibilika ngokusebenza kwewashi noma ukuxhumana kwedatha, isikhathi sokuphumula kufanele simiselwe isikhathi eside kunaleso esihleliwe, njengoba isikhathi sokuphumula sizoqala ukuncibilika okuyothi ngokuhamba kwesikhathi kulandelwe yileso esihleliwe. Ngokuphathelene nokuhluleka kwamandla, isikhathi sokuphumula sizogcinwa, futhi lapho amandla ebuya, isikhathi sokuphumula sizoqhubeka ukusuka kunani eligciniwe. Isikhathi sokuphumula asisebenzi uma sisethelwe ku-0. |

d03 | Isikhawu se-Def (0=off) |

| Ubuningi.. ubude be-defrost

Lesi silungiselelo yisikhathi sokuphepha ukuze ukuncibilika kumiswe uma bekungakaze kube khona ukuma okusekelwe ezingeni lokushisa noma ngokumiswa kweqhwa okuhlanganisiwe. |

d04 | I-Max Def. isikhathi |

| Isikhathi stagi-gering ye-defrost cut-ins ngesikhathi sokuqala

Umsebenzi ufanelekile kuphela uma unemishini yesiqandisi eminingana noma amaqembu lapho ufuna ukuthi i-defrost ibe stagmaqondana nomunye. Umsebenzi futhi ubalulekile kuphela uma ukhethe ukuncishiswa kweqhwa ngokuqala kwesikhawu (d03). Umsebenzi ubambezela isikhathi sesikhawu esingu-d03 ngenani elimisiwe lamaminithi, kodwa ukwenza kanye kuphela, futhi lokhu ekuncishisweni kweqhwa kokuqala okwenzeka lapho ivolumutagi-e ixhunywe kusilawuli. Umsebenzi uzosebenza ngemva kokuhluleka ngakunye ngakunye. |

d05 | Isikhathi Stagg. |

| Isikhathi sokuphumula

Lapha usetha isikhathi okumele sidlule kusukela ekuncipheni futhi kuze kube yilapho i-compressor iqala futhi. (Isikhathi lapho amanzi econsa ku-evaporator). |

d06 | Isikhathi sokuphumula |

| Ukubambezeleka kwefeni kuqala ngemva kokumiswa kwesithwathwa

Lapha usetha isikhathi okumele sidlule kusukela ekuqaleni kwe-compressor ngemva kokumiswa kweqhwa kuze kube yilapho isiphephetha-moya siqala futhi. (Isikhathi lapho amanzi “eboshelwa” ku-evaporator). |

d07 | I-FanStartDel |

| Umlandeli qala izinga lokushisa

I-fan ingase futhi iqalwe ngaphambi kwesikhathi kunalokho kushiwo ngaphansi kokuthi "Ukubambezeleka kokuqala kwabalandeli ngemva kokumiswa kweqhwa", uma inzwa ye-defrost S5 ibhalisa inani eliphansi kunaleli elibekwe lapha. |

d08 | I-FanStartTemp |

| Ukunqunywa kwefeni ngesikhathi sokushisa

Lapha ungasetha ukuthi ingabe ifeni kufanele isebenze ngesikhathi sokumiswa kweqhwa. 0: Imisiwe (Igijima ngesikhathi sokupompa phansi) 1: Ukugijima (kumiswe phakathi “nokulibaziseka kwabalandeli”) 2: Ukugijima ngesikhathi sokupompa phansi kanye nokuncibilika. Ngemva kwalokho, kuyamiswa. |

d09 | FanDuringDef |

| I-Defrost inzwa

Lapha uchaza inzwa ye-defrost. 0: Lutho, i-defrost isekelwe esikhathini 1: S5 2: shwi |

d10 | I-DefStopSens. |

| Pumpdown ukubambezela

Setha isikhathi lapho i-evaporator ithululwa khona esiqandisini ngaphambi kokuncibilika. |

d16 | Pompa phansi del. |

| I-Defrost on ukufuna – ukuhlanganisa isiqandisi isikhathi

Lapha, isikhathi sesiqandisi esivunyelwe ngaphandle kokuncibilika sisethiwe. Uma isikhathi sesidlulile, i-defrost izoqala. Ngokusetha = 0, umsebenzi uyasikwa. |

d18 | I-MaxTherRunT |

| I-Defrost on ukufuna – S5 izinga lokushisa

Isilawuli sizolandela ukusebenza kwe-evaporator, futhi ngezibalo zangaphakathi nezilinganiso zezinga lokushisa le-S5, sizokwazi ukuqalisa ukumisa isithwathwa lapho ukuhluka kwezinga lokushisa le-S5 kuba kukhulu kunalokho okudingekayo. Lapha usetha ukuthi isilayidi sezinga lokushisa le-S5 sikhulu kangakanani esingavunyelwa. Uma inani lidluliswa, i-defrost izoqala. Umsebenzi ungasetshenziswa kuphela ezinhlelweni ze-1:1 lapho izinga lokushisa elihwamukayo lizoba phansi ukuze kuqinisekiswe ukuthi izinga lokushisa lomoya lizogcinwa. Ezinhlelweni ezimaphakathi umsebenzi kumele unqanyulwe. Ngokusetha = 20, umsebenzi uyasikwa |

d19 | I-CutoutS5Dif. |

| Ubukhulu. ubude besikhathi -d- esibukweni

Ilawula ukufundwa kwe-“-d-” ngemva kokumiswa, ukuze okuthi “-d-” kuboniswe kuze kube yilapho izinga lokushisa lilungile, ukubambezeleka kwesethi kuphelelwe yisikhathi, noma i-alamu yezinga lokushisa iqale ukusebenza. |

d40 | I-Disp. D del. |

| Uma ufisa ukubona izinga lokushisa kusizwa sokumisa iqhwa, cindezela inkinobho yesilawuli ephansi kakhulu. | I-Defrost temp. | |

| Uma ufisa ukuqalisa i-defrost eyengeziwe, cindezela inkinobho yesilawuli ephansi kakhulu imizuzwana emine.

Ungamisa i-defrost eqhubekayo ngendlela efanayo. |

Def Qala

Lapha ungaqala i-defrost eyenziwa ngesandla |

|

| I-LED engaphambili kwesilawuli izokhombisa ukuthi ngabe i-defrost iyaqhubeka. | I-Defrost Relay

Lapha ungafunda isimo se-relay ye-defrost noma ungaphoqa-ukulawula ukudluliselwa kumodi "Yokulawula mathupha". |

|

| Bamba Ngemva kweDef

Ibonisa VULIWE lapho isilawuli sisebenza ngokuncibilika okuhlanganisiwe. |

||

| Defrost State Status on defrost

1= phompa phansi / ncibilikisa |

| Umlandeli | Umlandeli ukulawula | |

| I-fan yema kusiminyanisa

Lapha ungakhetha ukuthi ingabe ifeni izomiswa yini uma i-compressor inqanyulwa. |

F01 | Isitobhi sabalandeli CO

(Yebo = Umlandeli umile) |

| Ukubambezeleka kokuma kwefeni lapho i-compressor inqanyulwa

Uma ukhethe ukumisa isiphephetha-moya lapho i-compressor inqanyulwa, ungabambezela ukuma kwefeni lapho i-compressor iyekile. Lapha ungasetha ukubambezeleka kwesikhathi. |

F02 | Umlandeli del. CO |

| Izinga lokushisa lokumisa abalandeli

Umsebenzi umisa abalandeli esimweni sephutha, ukuze bangakwazi ukunikeza amandla kumshini. Uma inzwa ye-defrost ibhalisa izinga lokushisa eliphezulu kunaleli elibekwe lapha, abalandeli bazomiswa. Kuzoba khona ukuqalisa kabusha ku-2 K ngaphansi kwesilungiselelo. Umsebenzi awusebenzi ngesikhathi sokumiswa kweqhwa noma ukuqalisa ngemva kokumiswa kweqhwa. Ngokusetha +50°C, umsebenzi uyaphazamiseka. |

F04 | I-FanStopTemp. |

| I-LED ngaphambili kwesilawuli izokhombisa ukuthi ifeni iyasebenza yini. | Ukudluliswa kwabalandeli

Lapha ungafunda isimo se-relay yabalandeli, noma uphoqelele ukulawula i-relay kumodi "Yokulawula mathupha". |

| Umsebenzi we-defrosting wangaphakathi/iwashi | ||

| (Ayisetshenziswa uma ishejuli yokuqeda isithwathwa yangaphandle isetshenziswa ngokuxhumana kwedatha.) Kungasethwa izikhathi ezingafika kweziyisithupha ukuze kuqalwe iqhwa usuku lonke. | ||

| Ukuqala kwe-Defrost, ukulungiselelwa kwehora | t01-t06 | |

| Isiqalo sokuncibilika, ukulungiselelwa kweminithi (1 no-11 kuhlangene, njll.) Uma konke okuthi t01 kuya ku-t16 kulingana no-0, iwashi ngeke liqale ukuncibilika. | t11-t16 | |

| Isikhathi sangempela iwashi

Ukusetha iwashi kuyadingeka kuphela uma kungekho ukuxhumana kwedatha. Uma kwenzeka ukwehluleka kwamandla okungaphansi kwamahora amane, umsebenzi wewashi uzogcinwa. Uma ukhweza imojuli yebhethri umsebenzi wewashi ungagcinwa isikhathi eside. Kukhona futhi inkomba yedethi esetshenziselwa ukubhaliswa kwezilinganiso zokushisa. |

||

| Iwashi: Ukulungiselelwa kwehora | t07 | |

| Iwashi: Ukulungiselelwa kwemizuzu | t08 | |

| Iwashi: Ukulungiselelwa kosuku | t45 | |

| Iwashi: Ukulungiselelwa kwenyanga | t46 | |

| Iwashi: Ukulungiselelwa konyaka | t47 | |

| Okunhlobonhlobo | Okunhlobonhlobo | |

| Ukubambezeleka kwesignali yokuphumayo ngemva kokuqala

Ngemva kokuhluleka kwamandla, imisebenzi yesilawuli ingabambezeleka ukuze kugwenywe ukulayishwa ngokweqile kwenethiwekhi yokuphakela ugesi. Lapha ungasetha ukubambezeleka kwesikhathi. |

o01 | I-DelayOfOutp. |

| Idijithali okokufaka isignali – DI1

Isilawuli sinokufaka kwedijithali 1, okungasetshenziselwa omunye wale misebenzi elandelayo: Valiwe: Okokufaka akusetshenzisiwe 1. Ukuboniswa kwesimo somsebenzi wothintana naye 2. Umsebenzi womnyango: Uma okokufaka kuvuliwe, kubonisa ukuthi umnyango uvuliwe. Isiqandisi nabalandeli kumisiwe. Uma ukusetha isikhathi kokuthi “A4” kudluliswa, kuzonikezwa i-alamu futhi isiqandisi sizoqaliswa kabusha. 3. I-alamu yomnyango: Uma okokufaka kuvuliwe, kubonisa ukuthi umnyango uvuliwe. Uma isikhathi sokusethwa kokuthi “A4” sesidlulile, kuzoba ne-alamu. 4. I-Defrost: Umsebenzi uqalwa ngesignali ye-pulse. Isilawuli sizobhalisa lapho okokufaka kwe-DI kwenziwa kusebenze. Isilawuli sizobe sesiqala umjikelezo wokususa uqhwa. Uma isignali izotholwa izilawuli ezimbalwa kubalulekile ukuthi KONKE ukuxhumana kufakwe ngendlela efanayo (DI ukuya ku-DI kanye ne-GND kuya ku-GND). 5. Iswishi eyinhloko: Umthethonqubo wenziwa lapho okokufaka kufushane, futhi ukulawulwa kumiswa lapho okokufaka kufakwa ku-pos. VALIWE. 6. Ukusebenza kwasebusuku: Uma okokufaka kufushane, kuzoba nomthetho wokusebenza ebusuku. 7. Ukususwa kwereferensi lapho i-DI1 ine-circuited short-circuited. Ukususwa ngo-“r40”. 8. Umsebenzi we-alamu ohlukile: I-alamu izonikezwa uma okokufaka kufinyezwa kafushane. 9. Umsebenzi we-alamu ohlukile: I-alamu izonikezwa lapho okokufaka kuvulwa. (Okwesi-8 no-9, ukubambezeleka kwesikhathi kusethwe ku-A27) 10. Ukuhlanzwa kwekesi: Umsebenzi uqalwa ngesignali yokushaya kwenhliziyo. Cf.. futhi incazelo ku. |

o02 | I-DI 1 Config.

Incazelo yenzeka ngenani lenombolo eliboniswa kwesokunxele.

(0 = ivaliwe)

Isimo se-DI (Isilinganiso) Isimo samanje sokokufaka kwe-DI siboniswa lapha. VULIWE noma VALIWE. |

| Uma isilawuli sakhelwe kunethiwekhi enokuxhumana kwedatha, kufanele sibe nekheli, futhi isango elikhulu lokuxhumana kwedatha kufanele-ke lazi leli kheli.

Lezi zilungiselelo zingenziwa kuphela uma imojula yokuxhumana kwedatha ifakwe kusilawuli futhi ukufakwa kwekhebula lokuxhumana kwedatha sekuqediwe. Lokhu kufakwa kushiwo kudokhumenti ehlukile, “RC8AC”. Ikheli lisethwe phakathi kuka-1 no-60 (119), isango linqunyiwe. Ikheli lithunyelwa esangweni lapho imenyu isethwe ku-pos. VULIWE KUBALULEKILE: Ngaphambi kokuthi usethe u-o04, KUMELE usethe u-o61. Uma kungenjalo, uzobe udlulisela- Ukuthola idatha engalungile. |

Ngemva kokufakwa kwemojula yokuxhumana kwedatha, isilawuli singasebenza ngokulingana nezinye izilawuli kuzilawuli zesiqandisi ze-ADAP- KOOL®. | |

| o03 | ||

| o04 | ||

| Ukufinyelela ikhodi 1 (Ukufinyelela ku konke izilungiselelo)

Uma izilungiselelo kusilawuli kufanele zivikelwe ngekhodi yokufinyelela, ungasetha inani lenombolo phakathi kuka-0 no-100. Uma kungenjalo, ungakhansela umsebenzi ngokusetha u-0. (U-99 uzohlale ekunikeza ukufinyelela.) |

o05 | – |

| Inzwa uhlobo

Imvamisa, kusetshenziswa inzwa ye-Pt 1000 enokunemba okukhulu kwesignali. Kodwa ungasebenzisa futhi inzwa ngenye ukunemba kwesignali. Lokho kungase kube inzwa ye-PTC 1000 (1000 ohm) noma inzwa ye-NTC (5000 Ohm ku-25°C). Zonke izinzwa ezifakiwe kufanele zibe zohlobo olufanayo. |

o06 | I-SensorConfig Pt = 0

I-PTC = 1 I-NTC = 2 |

| Ukufundwa kwendawo kwenguqulo yesofthiwe | o08 | Uhlobo lwe-SW |

| Bonisa isinyathelo

Yebo: Inikeza izinyathelo zika-0.5° Cha: Inikeza izinyathelo zika-0.1° |

o15 | I-Disp. Isinyathelo = 0.5 |

| Ubukhulu.. isikhathi sokulinda ngemva kokumiswa kweqhwa okuhlanganisiwe

Uma isilawuli sesiqedile ukuncibilika sizolinda isignali etshela ukuthi isiqandisi singaqaliswa kabusha. Uma lesi siginali yehluleka ukuvela ngesizathu esisodwa noma esinye, isilawuli ngokwaso sizoqala isiqandisi uma lesi sikhathi sokulinda sesidlulile. |

o16 | I-Max HoldTime |

| Idijithali okokufaka isignali – D2

Isilawuli sinokufaka kwedijithali 2, okungasetshenziselwa omunye wale misebenzi elandelayo: Valiwe: Okokufaka akusetshenzisiwe. 1. Ukuboniswa kwesimo somsebenzi wothintana naye 2. Umsebenzi womnyango: Uma okokufaka kuvuliwe kubonisa ukuthi umnyango uvuliwe. Isiqandisi nabalandeli bayamiswa. Uma ukusetha isikhathi kokuthi “A4” kudluliswa, kuzonikezwa i-alamu futhi kuqaliswe kabusha isiqandisi. 3. I-alamu yomnyango: Uma okokufaka kuvuliwe, kubonisa ukuthi umnyango uvuliwe. Uma isikhathi sokusethwa kokuthi “A4” sesidlulile, kuzonikezwa i-alamu. 4. I-Defrost: Umsebenzi uqalwa ngesignali ye-pulse. Isilawuli sizobhalisa lapho okokufaka kwe-DI kwenziwa kusebenze. Isilawuli sizobe sesiqala umjikelezo wokususa uqhwa. Uma isignali izotholwa izilawuli ezimbalwa kubalulekile ukuthi KONKE ukuxhumana kufakwe ngendlela efanayo (DI ukuya ku-DI kanye ne-GND kuya ku-GND). 5. Iswishi eyinhloko: Umthethonqubo wenziwa lapho okokufaka kufushane, futhi ukulawulwa kumiswa lapho okokufaka kufakwa ku-pos. VALIWE. 6. Ukusebenza kwasebusuku: Uma okokufaka kufushane, kuzoba nomthetho wokusebenza ebusuku. 7. Ukususwa kwereferensi lapho i-DI2 ine-circuited short-circuited. Ukususwa ngo-“r40”. 8. Umsebenzi we-alamu ohlukile: I-alamu izonikezwa uma okokufaka kufinyezwa kafushane. 9. Umsebenzi we-alamu ohlukile: I-alamu izonikezwa lapho okokufaka kuvulwa. 10. Ukuhlanzwa kwekesi: Umsebenzi uqalwa ngesignali yokushaya kwenhliziyo. Cf. nencazelo ekhasini lesi-4. 11. Ayisetshenziswa 12. Okokufaka kusetshenziselwa ukumisa iqhwa okudidiyelwe ngokuhlangana nezinye izilawuli zohlobo olufanayo. |

o37 | I-DI2 config. |

| Ukucushwa komsebenzi wokukhanya (dlulisa oku-4 ezinhlelweni 2 no-6)

1) I-relay iyanqamula phakathi nokusebenza kosuku 2) I-relay kufanele ilawulwe ngokuxhumana kwedatha 3) I-relay okufanele ilawulwe yi-switch yomnyango ichazwa ku-o02 noma ku-o37, lapho ukulungiselelwa kukhethwe khona ku-2 noma ku-3. Uma umnyango uvulwa, i-relay izongena phakathi. Uma umnyango uvaliwe futhi, kuzoba nokulibaziseka kwemizuzu emibili ngaphambi kokuba ukukhanya kucishwe. |

o38 | Ukulungisa ukukhanya |

| Ukwenza kusebenze i-relay yokukhanya

I-relay yokukhanya ingenziwa isebenze lapha, kodwa kuphela uma ichazwe ku-o38 ngokusetha 2. |

o39 | Isilawuli kude esikhanyayo |

| Ukushisa kwesitimela phakathi nokusebenza kwansuku zonke

Isikhathi se-ON sisethwe njengephesentitage yesikhathi. |

o41 | Railh.ON usuku% |

| Ukushisa kukaloliwe phakathi nokusebenza ebusuku

Isikhathi se-ON sisethwe njengephesentitage yesikhathi. |

o42 | Railh.ON ngt% |

| Umjikelezo wokushisa ujantshi

Isikhathi se-aggregate ISIKHATHI SESIKHATHI + nesikhathi sokuvala sisethwe ngamaminithi. |

o43 | Railh. umjikelezo |

| Icala ukuhlanza

Isimo somsebenzi singalandelwa lapha, noma umsebenzi ungaqalwa mathupha. 0 = Ukusebenza okujwayelekile (akukho ukuhlanzwa) 1 = Ukuhlanza nabalandeli abasebenza. Yonke eminye imiphumela ivaliwe 2 = Ukuhlanza ngabalandeli abamisiwe. Konke okukhiphayo kuvaliwe. Uma umsebenzi ulawulwa isignali kokokufaka kwe-DI1 noma kwe-DI2, isimo esifanelekile singakwazi kubonakala lapha kumenyu. |

o46 | Ikesi lihlanzekile |

| Ukukhethwa kwesicelo

Isilawuli singachazwa ngezindlela ezihlukahlukene. Lapha usetha ukuthi yiziphi izinhlelo zokusebenza ezi-5 ezidingekayo. Ungabona inhlolovo yezinhlelo zokusebenza. Le menyu ingasethwa kuphela lapho umthetho umisiwe, okungukuthi, “r12” isethwe ukuze ithi 0. |

o61 | - I-Appl. Imodi |

| Dlulisa a setha of izilungiselelo ku i isilawuli

Kungenzeka ukukhetha ukulungiselelwa okusheshayo kwenani lamapharamitha. Kuya ngokuthi uhlelo lokusebenza noma igumbi kufanele lilawulwe kanye nokuthi ukucwiliswa kwesithwathwa kuzomiswa ngokuya kwesikhathi noma ngokuya ngezinga lokushisa. Inhlolovo ingabonwa ekhasini 22. Le menyu ingasethwa kuphela lapho umthetho umisiwe, okungukuthi, “r12” isethwe ukuze ithi 0.

Ngemva kokusetha, inani lizobuyela kokuthi 0. Noma yikuphi ukulungiswa/ukusetha okulandelayo kwamapharamitha kungenziwa, njengoba kudingekile. |

o62 | – |

| Ukufinyelela ikhodi 2 (Ukufinyelela ku ukulungiswa)

Kukhona ukufinyelela ekulungisweni kwamanani, kodwa hhayi kuzilungiselelo zokumisa. Uma izilungiselelo kusilawuli kufanele zivikelwe ngekhodi yokufinyelela, ungasetha inani lenombolo phakathi kuka-0 no-100. Uma kungenjalo, ungakhansela umsebenzi ngokusetha u-0. Uma umsebenzi usetshenziswa, finyelela ikhodi 1 (o05) kufanele futhi kusetshenziswe. |

o64 | – |

| Londoloza njengezilungiselelo zasembonini

Ngalesi silungiselelo, ulondoloza izilungiselelo zangempela zesilawuli njengesilungiselelo esisha esiyisisekelo (izilungiselelo zangaphambilini zasembonini zibhalwa ngaphezulu). |

o67 | – |

| Isikhathi sokusebenza Funda ngokuphimisela

Ukufundwa kokusebenza kwesilawuli esinqwabelene ngezinsuku (okunikwe amandla nokuvula okuyinhloko). Ingasulwa noma ilungiswe lapho inkinobho enkulu ye-R12 icishiwe. |

P48 | Isikhathi sokusebenza seyunithi |

| Isicelo se-alamu yesevisi

Izinsuku zokusebenza ngaphambi kwesicelo se-alamu Yesevisi. Inani = 0 ikhubaza umsebenzi |

P91 | I-CondServ req |

| Ichaza isenzo lapho i-alamu evinjiwe i-Condenser isebenza

0 = Umsebenzi uvaliwe, 1 = Vala ukukhanya, 2 = Misa i-compressor, 3 = Ukukhanya nokucisha, 4 = Misa i-com, Ukushisa kukaloliwe nokukhanya kuvaliwe, 5 = I-Comp, Ukukhanya kanye ne-RH kuvaliwe |

P92 | Cond isenzo |

| Isikhathi sokubala imicimbi ye-condenser ngaphambi kokuma unomphela

Inombolo yamahora wokubala imicimbi. Imicimbi emidala kunesikhathi esimisiwe iyalahlwa. |

P93 | Isikhathi se-Cond |

| Inombolo yemicimbi ye-condenser phakathi nesikhathi esingaphambi kokuma unomphela

Isikhathi sichazwa ngepharamitha P93. Inani = 0 ikhubaza umsebenzi |

P94 | Cond Ev cnt |

| – – – Ukubuyisela emuva Ebusuku 0=Usuku

1=Ubusuku |

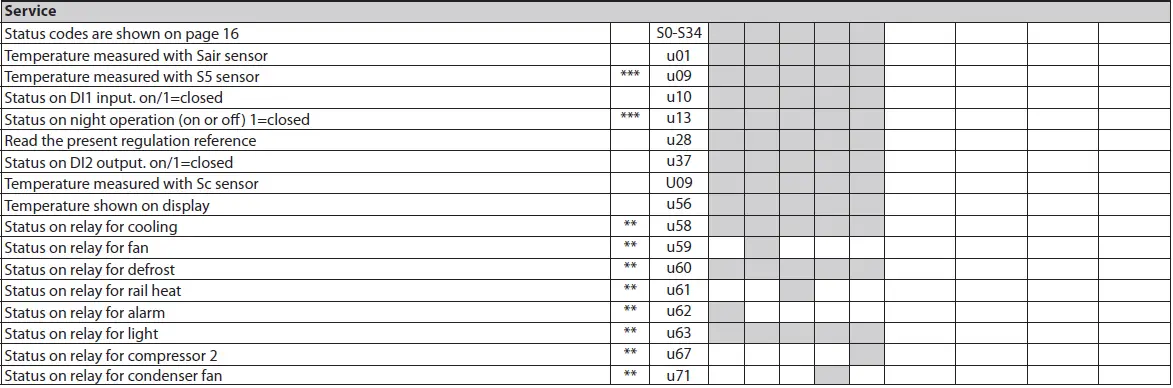

| Isevisi | Isevisi | |

| Izinga lokushisa likalwa ngenzwa ye-Sair | u01 | Sair temp. |

| Izinga lokushisa likalwa ngenzwa ye-S5 | u09 | Izinga lokushisa le-S5. |

| Isimo kokokufaka kwe-DI1. ku/1=kuvaliwe | u10 | Isimo se-DI1 |

| Isimo sokusebenza ebusuku (kuvuliwe noma kuvaliwe) 1=kuvaliwe | u13 | I-Night Cond. |

| Funda inkomba yamanje yomthetho | u28 | Temp. ref. |

| Isimo ekuphumeni kwe-DI2. ku/1=kuvaliwe | u37 | Isimo se-DI2 |

| Izinga lokushisa likalwa ngenzwa ye-Sc | U09 | Sc temp. |

| Izinga lokushisa liboniswa esibukweni | u56 | Bonisa umoya |

| ** Isimo sokudlulisa ukupholisa | u58 | I-Comp1/LLSV |

| ** Isimo sokudluliswa kwe-fan | u59 | Ukudluliselwa kwabalandeli |

| ** Isimo edluliselwe for defrost | u60 | Def. udlulise |

| ** Isimo sokudluliswa kwesitimela sokushisa kwesitimela | u61 | Railh. udlulise |

| ** Isimo sokudluliswa kwe-alamu | u62 | I-alamu edluliselwe |

| ** Isimo sokudlulisa ukukhanya | u63 | Ukudlulisa ukukhanya |

| ** Isimo sokudluliswa kwe-compressor 2 | u67 | I-Comp2 edluliselwe |

| ** Isimo sokudluliswa kwe-condenser fan | u71 | I-Condenser fan edluliselwe |

| *) Akuzona zonke izinto ezizoboniswa. Umsebenzi wohlelo olukhethiwe kuphela ongabonwa. |

| Iphutha umyalezo | Ama-alamu | |

| Esimeni sephutha ama-LED angaphambili azokhanyisa futhi i-alamu izovulwa. Uma ucindezela inkinobho ephezulu kulesi simo ungabona umbiko we-alamu kusibonisi. Uma kukhona abaningi qhubeka nokuphusha ukuze ubabone.

Kunezinhlobo ezimbili zemibiko yephutha - kungaba i-alamu eyenzeka phakathi nokusebenza kwansuku zonke, noma kungase kube khona iphutha ekufakeni. Ama-alamu ngeke abonakale kuze kube yilapho ukubambezeleka kwesikhathi esimisiwe kuphelelwe yisikhathi. Ama-alamu e-E, ngakolunye uhlangothi, azobonakala lapho iphutha lenzeka. (I-alamu ngeke ibonakale inqobo nje uma kukhona i-alamu ka-E esebenzayo.) Nansi imilayezo engavela: |

1 = i-alamu |

|

| I-A1: I-alamu yokushisa okuphezulu | Phezulu t. i-alamu | |

| A2: I-alamu yokushisa ephansi | Okuphansi t. i-alamu | |

| A4: I-alamu yomnyango | I-Alarm Yomnyango | |

| A5: Ulwazi. Ipharamitha engu-o16 iphelelwe yisikhathi | I-Max Hold Time | |

| A15: I-alamu. Isiginali evela ku-DI1 okokufaka | I-alamu ye-DI1 | |

| A16: I-alamu. Isiginali evela ku-DI2 okokufaka | I-alamu ye-DI2 | |

| I-A45: Indawo elindile (isiqandisi esimisiwe nge-R12 noma i-DI input) (I-alamu edluliswayo ngeke yenziwe isebenze) | Imodi yokulinda | |

| A59: Ukuhlanzwa kwecala. Isiginali evela ku-DI1 noma okokufaka kwe-DI2 | Ukuhlanzwa kwecala | |

| I-A61: I-alamu yezinga lokushisa le-Condenser | Khombisa i-alamu | |

| I-A80: I-alamu evinjiwe i-Condenser | I-Cond ivinjiwe | |

| I-AA4: I-alamu yesicelo sesevisi | Cond ServReq | |

| Ubukhulu. def isikhathi | ||

| E1: Amaphutha kusilawuli | Iphutha le-EKC | |

| I-E6: Iphutha ewashini lesikhathi sangempela. Hlola ibhethri / setha kabusha iwashi. | – | |

| I-E27: Iphutha lenzwa ku-S5 | Iphutha le-S5 | |

| I-E29: Iphutha lenzwa ye-Sair | Iphutha le-Sair | |

| I-E64: Iphutha lenzwa ye-Sc | Iphutha le-Sc | |

| I-alamu izindawo okuyiwa kuzo | ||

| Ukubaluleka kwama-alamu angawodwana kungachazwa ngokulungiselelwa (0, 1, 2, noma 3) |

| Isebenza isimo | (Isikali) | |

| Isilawuli sidlula ezimeni ezithile zokulawula lapho sivele silinde iphuzu elilandelayo lomthethonqubo. Ukwenza lezi zimo "kungani kungenzeki" izimo

ebonakalayo, ungabona isimo sokusebenza esibukweni. Cindezela kafushane (1s) inkinobho engenhla. Uma kunekhodi yesimo, izovezwa esibukweni. Amakhodi esimo angawodwana anezincazelo ezilandelayo: |

Isifunda se-EKC:

(Kuboniswa kuzo zonke izibonisi zemenyu) |

|

| S0: Ukulawula | 0 | |

| I-S1: Ilinde ukuphela kwe-defrost ehlanganisiwe | 1 | |

| I-S2: Uma i-compressor isebenza, kufanele isebenze okungenani imizuzu engu-x. | 2 | |

| S3: Uma i-compressor imiswa, kufanele ihlale imile okungenani imizuzu engu-x. | 3 | |

| I-S4: I-evaporator iyaconsa bese ilinda ukuthi isikhathi siphele | 4 | |

| S10: Isiqandisi simiswe iswishi eyinhloko. Kungaba ngo-R12 noma okokufaka kwe-DI | 10 | |

| I-S11: Isiqandisi simiswe yi-thermostat | 11 | |

| I-S14: Ukulandelana kwe-Defrost. Ukuqedwa kweqhwa kuyaqhubeka | 14 | |

| I-S15: Ukulandelana kwe-Defrost. Ukubambezeleka kwabalandeli - amanzi anamathela ku-evaporator | 15 | |

| S17: Umnyango uvuliwe. Okokufaka kwe-DI kuvuliwe | 17 | |

| S20: Ukupholisa okuphuthumayo *) | 20 | |

| I-S25: Ukulawula okwenziwa ngesandla ngesandla | 25 | |

| S29: Ukuhlanzwa kwecala | 29 | |

| S32: Ukubambezeleka kokuphumayo ngesikhathi sokuqalisa | 32 | |

| S34: I-Condenser evinjiwe umcimbi uyasebenza | 34 | |

| Okunye ekhombisa: | ||

| okungezona: Izinga lokushisa le-defrost alikwazi ukuboniswa. Kukhona ukuma okusekelwe esikhathini | ||

| -d-: I-Defrost iyaqhubeka / Ukupholisa kokuqala ngemva kokumiswa kweqhwa | ||

| PS: Kudingeka iphasiwedi. Setha iphasiwedi |

Ukupholisa izimo eziphuthumayo kuzosebenza uma kuntuleka isignali evela kunzwa ye-Sair. Umthethonqubo uzoqhubeka ne-avareji ebhalisiwe yokusika. Kunamanani amabili abhalisiwe - elilodwa elokusebenza emini nelilodwa elokusebenza ebusuku.

Isexwayiso! Ukuqala okuqondile kwama-compressor *

- Ukuze uvimbele ukuphuka kwe-compressor, amapharamitha u-c01 no-c02 kufanele asethwe ngokuvumelana nezidingo zomphakeli noma ngokujwayelekile:

- I-Hermetic Compressors c02 min. 5 amaminithi

- I-Semihermetic Compressors c02 min. 8 amaminithi c01 min. Imizuzu emi-2 ukuya kwemi-5 (injini isuka ku-5 - 15 kW)

- Ukwenza kusebenze okuqondile kwamavalvu e-solenoid akudingi izilungiselelo ezihlukile kwefekthri (0)

Ukusebenza

Bonisa

- Amanani azoboniswa namadijithi amathathu, futhi ngesilungiselelo ungakwazi ukunquma ukuthi izinga lokushisa lizoboniswa ngo-°C noma ngo-°F.

Ama-diode akhipha ukukhanya (i-LED) kuphaneli yangaphambili

Amanye ama-LED kuphaneli yangaphambili azokhanya uma i-relay engumnikazi icushiwe.

= Isiqandisi

= Isiqandisi = Ukuncibilika

= Ukuncibilika = Ukugijima kwabalandeli

= Ukugijima kwabalandeli

Ama-diode akhipha ukukhanya azokhanya uma kune-alamu.

Kulesi simo ungadawuniloda ikhodi yephutha kusibonisi futhi ukhansele/usayinele i-alamu ngokunikeza ifindo eliphezulu ukusunduza kafushane.

I-Defrost

Ngesikhathi se-defrost a, u-d- uyakhonjiswa esibukweni.

Ngemuva kokuthi i-defrost isiqediwe, ukufundwa kwe--d- kuzoqhutshwa kuze kube yilapho kuhlangatshezwana nemibandela elandelayo:

- Izinga lokushisa lilungile (ngaphansi komkhawulo wokusika)

- I-alamu yezinga lokushisa eliphezulu iqala ukusebenza

- Ukubambezeleka okusethwe ngepharamitha ye-d40 kuphelelwa yisikhathi

- Umthetho umiswa nge-“Main switch”

Izinkinobho

Uma ufuna ukushintsha isilungiselelo, izinkinobho ezingenhla neziphansi zizokunikeza inani eliphezulu noma eliphansi, kuye ngenkinobho oyicindezelayo. Kodwa ngaphambi kokuthi ushintshe inani, kufanele ube nokufinyelela kumenyu. Lokhu ukuthola ngokucindezela inkinobho engenhla imizuzwana embalwa - uzofaka ikholomu namakhodi epharamitha. Thola ikhodi yepharamitha ofuna ukuyishintsha bese ucindezela izinkinobho ezimaphakathi kuze kube yilapho kuboniswa inani lepharamitha. Uma usushintshile inani, londoloza inani elisha ngokucindezela futhi inkinobho ephakathi nendawo.

Exampkancane:

Setha imenyu

- Cindezela inkinobho engenhla kuze kuvele ipharamitha ethi r01.

- Cindezela inkinobho engenhla noma engezansi bese uthola ipharamitha ofuna ukuyishintsha.

- Cindezela inkinobho ephakathi kuze kuvele inani lepharamitha.

- Cindezela inkinobho engenhla noma engezansi bese ukhetha inani elisha.

- Cindezela inkinobho ephakathi futhi ukuze umise inani.

I-alamu yokusika, i-alamu yokudlulisa / irisidi/bona ikhodi ye-alamu

- Cindezela inkinobho engenhla maduze.

- Uma kukhona amakhodi amaningana e-alamu, atholakala ku-rolling stack.

- Cindezela inkinobho ephezulu kakhulu noma ephansi ukuze uskene isitaki esigoqayo.

Setha izinga lokushisa

- Cindezela inkinobho ephakathi kuze kubonakale inani lokushisa

- Cindezela inkinobho engenhla noma engezansi bese ukhetha inani elisha

- Cindezela inkinobho ephakathi futhi ukuze uphethe isilungiselelo.

Ifunda izinga lokushisa kunzwa ye-defrost

- Cindezela inkinobho engezansi maduze

Ukuqala ngokuzenzela noma ukumisa i-defrost

- Cindezela inkinobho engezansi imizuzwana emine.

- (Nakuba kungenjalo isicelo 4).

Qala kahle

Ngenqubo elandelayo, ungaqala ukulawula ngokushesha okukhulu:

- Vula ipharamitha engu-r12 bese umisa isimiso (eyunithi entsha nengasethiwe ngaphambili, u-r12 uzobe esethelwe ku-0, okusho ukuthi umthethonqubo omisiwe.)

- Khetha ukuxhumana okuncike kuhlelo lokusebenza ngokusekelwe emidwebeni.

- Vula ipharamitha u-o61 bese usetha inombolo yokuxhumana kagesi kuyo.

- Manje khetha enye yezilungiselelo ezisethiwe etafuleni.

- Vula ipharamitha u-o62 bese usetha inombolo yohlu lokusethwa ngaphambilini. Izilungiselelo ezimbalwa ezikhethiwe manje zizodluliselwa kumenyu.

- Vula ipharamitha r12 bese uqala umthethonqubo

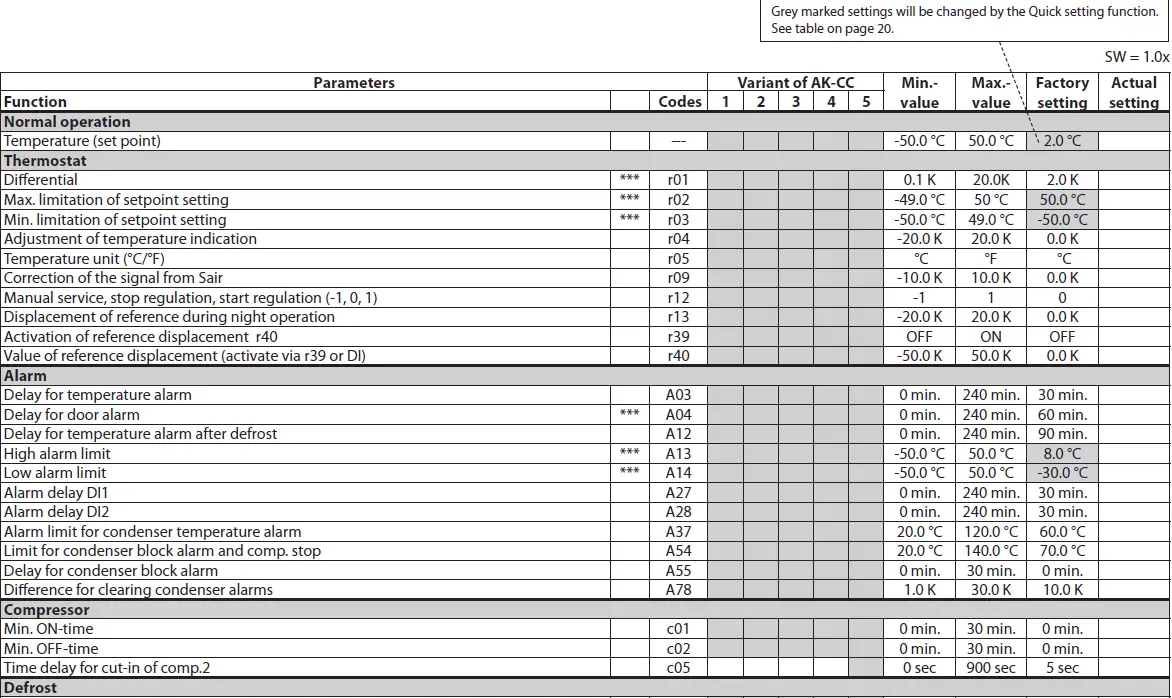

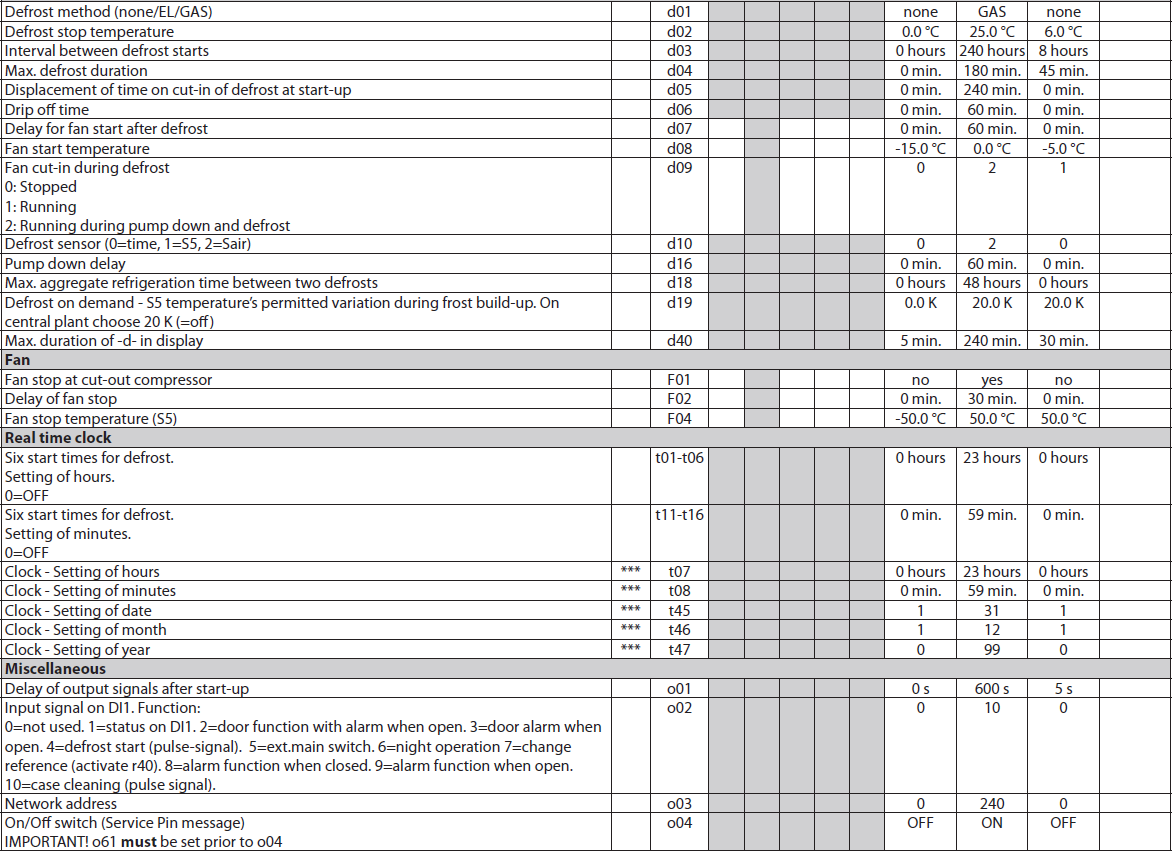

- Dlula kunhlolovo yezilungiselelo zefekthri. Amanani kumaseli ampunga ashintshwa ngokuya ngezilungiselelo ozikhethayo. Yenza noma yiziphi izinguquko ezidingekayo kumapharamitha afanele.

- Okwenethiwekhi. Setha ikheli kokuthi o03 bese ufaka kuyunithi yesistimu ngokuskena, noma i-Lon ngokusetha okuthi o04.

- Ingasethwa kuphela lapho umthetho umisiwe (r12=0)

- Ingalawulwa ngesandla, kodwa kuphela uma r12=-1

- Ngekhodi yokufinyelela 2 ukufinyelela kulawa mamenyu kuzonqunyelwa

Isilungiselelo sasefekthri

Uma udinga ukubuyela kumanani asethwe njengasekuqaleni, yenza okulandelayo:

- Sika umthamo wokunikezwayotage kusilawuli

- Gcina zombili izinkinobho zicindezelekile ngesikhathi esifanayo njengoba uxhuma kabusha ivolumu yokunikezelatage

| Ithebula lezilungiselelo ezisheshayo | Ikhabethe leMT (elipholile). | Ikhabhinethi ye-LT (isithwathwa). |

| Ukusetha ngaphambilini – nge o62 | 1 | 2 |

| Izinga lokushisa (SP) | 4.0 °C | -24.0 °C |

| Ubukhulu. isikhashana. isilungiselelo (r02) | 6.0 °C | -22.0 °C |

| Okuncane. isikhashana. isilungiselelo (r03) | 2.0 °C | -26.0 °C |

| Umkhawulo we-alamu uphezulu (A13) | 10.0 °C | -15.0 °C |

| Umkhawulo we-alamu uphansi (A14) | -5.0 °C | -30.0 °C |

Khipha

- Isilawuli siqukethe inani lemisebenzi engasetshenziswa kanye nomsebenzi wokukhipha ku-master gateway / Isiphathi Sesistimu.

| Umsebenzi nge-data com- umculo | Imisebenzi ezosetshenziswa emsebenzini wokukhipha wesango | Ipharamitha esetshenzisiwe ku I-AK-CC 210B |

| Ukuqala kwe-defrosting | Isikhathi sokulawula i-Defrost | – – – Def. qala |

| I-defrost ehlanganisiwe | Ukulawula i-Defrost | – – – HoldAfterDef u60 Def.relay |

| Ukubuyela emuva ebusuku | Ukulawula usuku/ubusuku Isheduli yesikhathi | – – – Ukusetha ebusuku |

| Ukulawula ukukhanya | Ukulawula usuku/ubusuku Isheduli yesikhathi | o39 Isilawuli kude esikhanyayo |

Iya-oda

Ukuxhumana

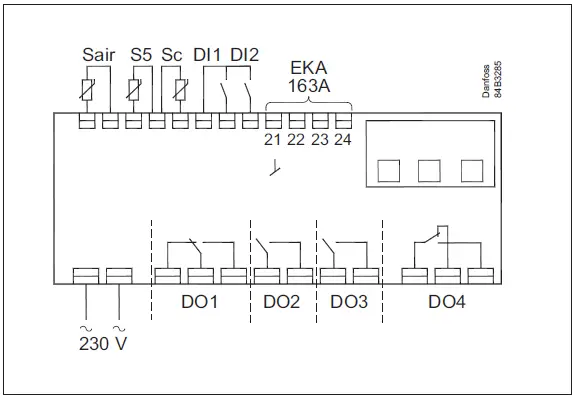

Ukunikezwa kwamandla kagesi

- 230 V AC

Izinzwa

- Izinga lokushisa le-thermostat likalwa nge-Sair.

- I-S5 iyinzwa ye-defrost futhi isetshenziswa uma i-defrost kufanele imiswe ngokuya ngezinga lokushisa.

- Inzwa ye-Sc isetshenziselwa ukuqapha nokulawula izinga lokushisa le-condenser.

Amasiginali Wokuvula/Ukuvala

- Okokufaka okusikiwe kuzovula umsebenzi. Imisebenzi engenzeka ichazwe kumamenyu o02 kanye no-o37.

EKA 163A – Isibonisi sangaphandle

- Lapha, uhlobo lwesibonisi sangaphandle i-EKA 163A noma i-EKA 164A ingaxhunywa - sicela ubheke Imiyalelo ye-EKA 16xA (incwadi no. 084R9970)

Ukudluliselwa

- Ukusetshenziswa okuvamile kubalulwe lapha. Bheka futhi lapho izinhlelo zokusebenza ezahlukene zikhonjiswa khona.

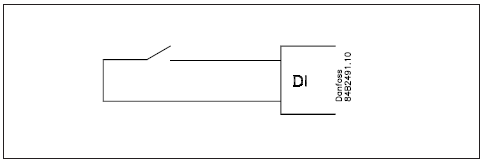

- DO1: Isiqandisi. I-relay izongena lapho isilawuli sifuna isiqandisi

- I-DO2: I-Defrost. I-relay izongena lapho ukucwiliswa kweqhwa kuqhubeka

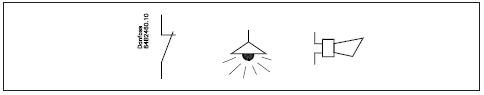

- I-DO3: Ukukhanya. I-relay iyanqamula uma isibani kufanele sikhanyiswe.

- I-DO4: Kungaba yi-alamu, ukushisa kukaloliwe, ifeni, i-condenser fan noma i-compressor 2.

- I-alamu: Cf. umdwebo. I-relay iyasikwa phakathi ngesikhathi sokusebenza okujwayelekile futhi iyanqamuka ezimeni ze-alamu nalapho isilawuli sesifile (siphelelwa amandla)

- Ukushisa kukaloliwe: I-relay iyanqamuka lapho ukushisa kukaloliwe kuzosebenza.

- Abalandeli: I-relay izongena uma abalandeli sekufanele basebenze.

- I-Condenser fan: I-relay ilandela i-compressor ngaphandle kwalapho i-defrost.

- I-Compressor 2: I-relay izongena lapho isinyathelo sesiqandisi sesi-2 kufanele sinqunywe.

Ukuxhumana kwedatha

- Isilawuli sitholakala kuzinguqulo ezimbalwa lapho ukuxhumana kwedatha kungenziwa ngenye yalezi zinhlelo ezilandelayo: MODBUS noma i-LON-RS485.

- Uma ukuxhumana kwedatha kusetshenziswa, ukufakwa kwekhebula lokuxhumana kwedatha kufanele kwenziwe ngendlela efanele.

- Bona izincwadi ezihlukene No. RC8AC...

Umsindo kagesi

Amakhebuli wezinzwa, okokufaka kwe-DI kanye nokuxhumana kwedatha kufanele kube

agcinwe ahlukene kwezinye izintambo zikagesi:

- Sebenzisa amathreyi ekhebula ahlukene

- Gcina ibanga phakathi kwezintambo okungenani libe ngu-10 cm

- Izintambo ezinde kokokufaka kwe-DI kufanele zigwenywe

Idatha

| Ukunikezwa kwevoltage | 230 V AC +10/-15 %. 2.5 VA, 50/60 Hz | ||

| Izinzwa 3 ama-pcs noma | Pt 1000 noma

I-PTC 1000 noma I-NTC-M2020 (5000 ohm / 25 °C) |

||

| Ukunemba | Ibanga lokulinganisa | -60 - 99 °C | |

| Isilawuli | ±1 K ngaphansi -35 °C

±0.5 K phakathi -35 - 25 °C ±1 K ngaphezu kuka-25 °C |

||

| Inzwa ye-Pt 1000 | ±0.3 K ku-0°C

±0.005 K ngedigri ngayinye |

||

| Bonisa | I-LED, amadijithi angu-3 | ||

| Isibonisi sangaphandle | EKA 163A | ||

| Okokufaka kwedijithali | Isignali evela emisebenzini yokuxhumana. Izidingo zoxhumana nabo: I-Gold plating, Ubude bekhebula kufanele bube bukhulu. 15 m

Sebenzisa ama-relay asizayo uma ikhebuli iyinde. |

||

| Ikhebuli yokuxhuma kagesi | Ubukhulu. 1.5 mm2 ikhebula le-multi-core | ||

| Ukudluliselwa* | CE

(250 V AC) |

UL *** (240 V AC) | |

| DO1.

Isiqandisi |

8 (6) A | 10 A I-Resistive 5FLA, 30LRA | |

| DO2. Defrost | 8 (6) A | 10 A I-Resistive 5FLA, 30LRA | |

| DO3. Umlandeli | 6 (3) A | 6 A I-Resistive 3FLA, 18LRA

131 VA Umshayeli wendiza umsebenzi |

|

| DO4. I-alamu | 4 (1) A

Okuncane. 100 mA** |

4 Ukungazweli

131 VA Umshayeli wendiza umsebenzi |

|

| Imvelo | 0 - 55 °C, ngesikhathi sokusebenza

-40 - 70 °C, ngesikhathi sokuthutha |

||

| I-20 - 80% Rh, ayifinyeziwe | |||

| Akukho thonya lokushaqeka/ukudlidliza | |||

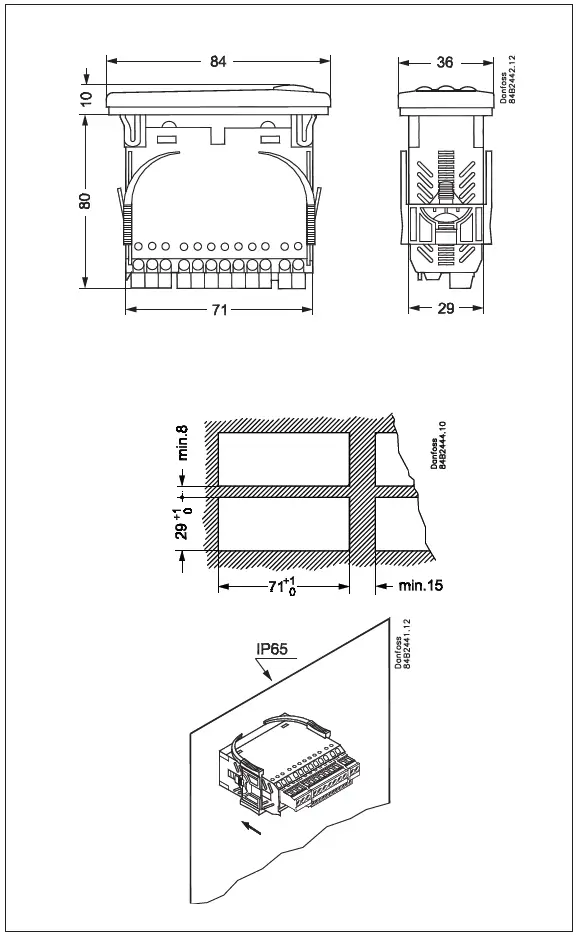

| Ukuminyana | IP65 ukusuka ngaphambili.

Izinkinobho nokupakisha kushumekwe ngaphambili. |

||

| Indawo yokubalekela iwashi |

4 amahora |

||

| Izimvume

|

I-EU Low Voltage Izimfuno ze-EMC kumele zithotshelwe

I-LVD ihlolwe i-acc. I-EN 60730-1 kanye ne-EN 60730-2-9, A1, A2 I-EMC ihlolwe i-acc. I-EN 61000-6-3 kanye ne-EN 61000-6-2 |

||

- I-DO1 kanye ne-DO2 ziyi-16 A ama-relay. I-8 A eshiwo inganyuswa ifike ku-10 A lapho izinga lokushisa lendawo ligcinwa lingaphansi kuka-50 °C. I-DO3 ne-DO4 ziyi-8A edluliselwe. Ubukhulu. Umthwalo kufanele ugcinwe.

- Ukufakwa kwegolide kuqinisekisa umsebenzi omuhle ngemithwalo encane yokuxhumana

- Ukugunyazwa kwe-UL okusekelwe kuma-couplings angu-30000.

U-Danfoss akakwazi ukwamukela isibopho ngamaphutha angaba khona kumakhathalogi, izincwajana, nokunye okuphrintiwe. I-Danfoss igodla ilungelo lokushintsha imikhiqizo yayo ngaphandle kwesaziso. Lokhu kusebenza futhi emikhiqizweni esivele ine-oda, inqobo nje uma lokho kuguqulwa kungenziwa ngaphandle kokuthi kube noshintsho oludingekayo emibhalweni osekuvunyelwene ngayo. d Zonke izimpawu zokuthengisa ezikulolu lwazi ziyimpahla yezinkampani ezifanele. I-Danfoss kanye nohlobo lwelogo ye-Danfoss yizimpawu zokuthengisa ze-Danfoss A/S. Wonke Amalungelo Agodliwe

FAQ

- Ngiyisetha kanjani inzwa ye-defrost?

- Ukuze usethe inzwa ye-defrost, yibeke ngokuqondile ku-evaporator ukuze uthole isignali elungile. Lokhu kuqinisekisa imijikelezo ye-defrost ephumelelayo.

- Ngingawamisa kanjani ama-alamu okushisa e-condenser?

- Ungamisa ama-alamu okushisa e-condenser ngokusetha umkhawulo we-Condenser Alarm kanye nomkhawulo we-Condenser Block Alarm. Chaza izenzo ngokusekelwe kule mikhawulo kupharamitha P92.

- Yini okufanele ngiyenze uma ama-compressor emiswa ngenxa yama-alamu abucayi?

- Uma ama-compressor amisiwe ngenxa yama-alamu abalulekile, ukusetha kabusha mathupha kuyadingeka ngaphambi kokuthi kuqale futhi. Hlola amapharamitha P93, P94, kanye ne-P92 ukuze ulungise ukuziphatha kwe-compressor.

Amadokhumenti / Izinsiza

|

I-Danfoss AK-CC 210B Isilawuli Sokulawula Izinga lokushisa [pdf] Umhlahlandlela Womsebenzisi I-AK-CC 210B Controller For Temperature Control, AK-CC 210B, Controller For Temperature Control, Temperature Control, Control |