I-Danfoss AK-CC 210 Isilawuli Sokulawula Izinga lokushisa

Imininingwane

- Umkhiqizo: Isilawuli sokulawula izinga lokushisa i-AK-CC 210

- Ubukhulu bezinzwa ze-thermostat ezixhunyiwe: 2

- Okokufaka kwedijithali: 2

Isingeniso

Isicelo

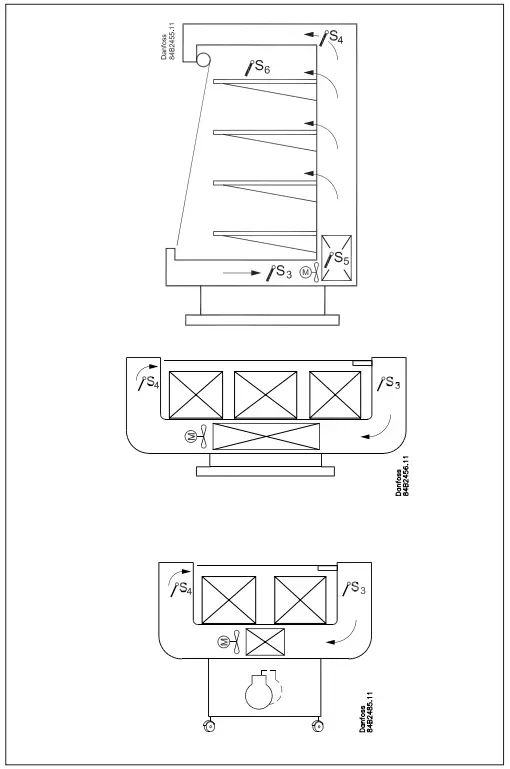

- Isilawuli sisetshenziselwa ukulawula izinga lokushisa eziqandisini zikagesi ezitolo ezinkulu

- Ngezinhlelo zokusebenza eziningi ezichazwe ngaphambilini iyunithi eyodwa izokunikeza izinketho eziningi. Ukuvumelana nezimo kuhlelelwe kokubili ukufakwa okusha kanye nesevisi yokuhweba ngeziqandisi

Isimiso

Isilawuli siqukethe isilawuli sezinga lokushisa lapho isignali ingatholwa kusuka kuzinzwa zokushisa eyodwa noma ezimbili.

Izinzwa ze-thermostat kungenzeka zibekwe ekugelezeni komoya obandayo ngemva kwe-evaporator, ekugelezeni komoya ofudumele ngaphambi nje kwe-evaporator, noma kokubili. Isilungiselelo sizonquma ukuthi amasiginali womabili azoba nethonya elikhulu kangakanani ekulawuleni.

Isilinganiso sokushisa kwe-defrost singatholwa ngokuqondile ngokusebenzisa inzwa ye-S5 noma ngokungaqondile ngokusebenzisa isilinganiso se-S4. Ukudluliselwa okune kuzosika imisebenzi edingekayo ngaphakathi nangaphandle - uhlelo lokusebenza lunquma ukuthi iyiphi. Izinketho yilezi ezilandelayo:

- Isiqandisi (i-compressor noma i-relay)

- Umlandeli

- I-Defrost

- Ukushisa kukaloliwe

- I-alamu

- Ukukhanya

- Abalandeli be-hotgas defrost

- Isiqandisi 2 (i-compressor 2 noma i-relay 2)

Izicelo ezehlukene zichazwe ekhasini 6.

I-Advantages

- Izinhlelo zokusebenza eziningi kuyunithi efanayo

- Isilawuli sinemisebenzi edidiyelwe yesiqandisi-zobuchwepheshe, ukuze singene esikhundleni salo lonke iqoqo lama-thermostats nezibali sikhathi.

- Izinkinobho nophawu kufakwe ngaphambili

- Ingakwazi ukulawula ama-compressor amabili

- Kulula ukukhweza ukuxhumana kwedatha

- Ukusetha okusheshayo

- Izinkomba zokushisa ezimbili

- Okokufaka kwedijithali kwemisebenzi ehlukahlukene

- Umsebenzi wewashi ngesipele se-super cap

- I-HACCP (Ukuhlaziywa Kwezingozi kanye Namaphuzu Okulawula Okubalulekile)

- Ukuqapha izinga lokushisa nokubhaliswa kwesikhathi ngezinga lokushisa eliphezulu kakhulu (bheka futhi ikhasi 19)

- Ukulinganisa kwasefekthri okuzoqinisekisa ukunemba okungcono kokulinganisa kunalokho okushiwo ku-EN ISO 23953-2 ejwayelekile ngaphandle kokulinganisa okulandelayo (inzwa ye-Pt 1000 ohm)

Ukusebenza

Izinzwa

Kungaxhunywa izinzwa ze-thermostat ezingafika kwezimbili kusilawuli. Isicelo esifanele sinquma ukuthi kanjani.

- Inzwa esemoyeni ngaphambi kwe-evaporator:

Lokhu kuxhumana kusetshenziswa ngokuyinhloko uma ukulawula kusekelwe endaweni. - Inzwa esemoyeni ngemva kwe-evaporator:

Lokhu kuxhumana kusetshenziswa ngokuyinhloko lapho isiqandisi kulawulwa futhi kunobungozi bezinga lokushisa eliphansi kakhulu eduze nemikhiqizo. - Inzwa ngaphambi nangemuva kwe-evaporator:

Lokhu kuxhumana kukunikeza ithuba lokujwayela i-thermostat, i-alamu thermostat kanye nesibonisi ohlelweni olufanele. Isignali eya ku-thermostat, i-alamu thermostat nesibonisi kusethwa njengenani elinesisindo phakathi kwamazinga okushisa amabili, futhi u-50% uzowathola ku-ex.ampnginikeza inani elifanayo kuzo zombili izinzwa.

Isignali eya ku-thermostat, i-alamu thermostat nesibonisi kungasethwa ngokuzimela ngaphandle kokunye. - Inzwa ye-Defrost

Isignali engcono kakhulu ephathelene nezinga lokushisa le-evaporator itholakala kunzwa yokuncibilikisa efakwe ngqo ku-evaporator. Lapha isignali ingase isetshenziswe umsebenzi we-defrost, ukuze i-defrost emfushane futhi eyonga amandla kakhulu ingenzeka.

Uma inzwa yokuncibilika ingadingeki, i-defrost ingamiswa ngokusekelwe ngesikhathi, noma i-S4 ingakhethwa.

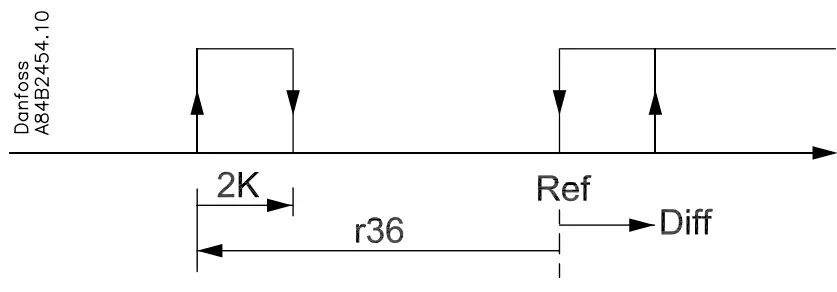

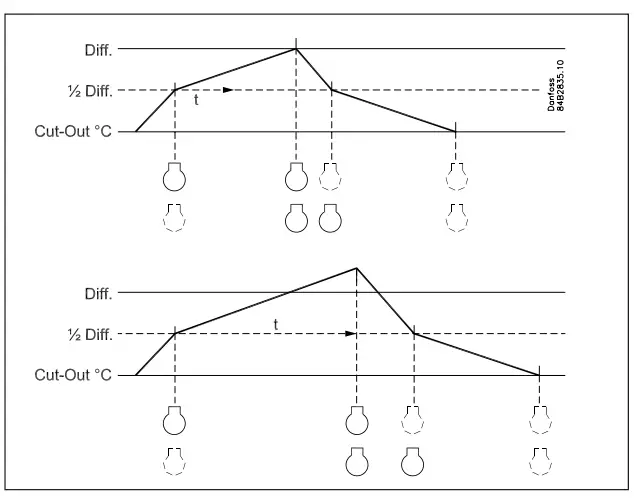

Ukulawula ama-compressor amabili

Lokhu kulawulwa kusetshenziselwa ukulawula ama-compressor amabili anosayizi ofanayo. Umgomo wokulawula ukuthi enye yama-compressor ixhuma ku-½ umehluko we-thermostat, kanti enye ngokuhluka okugcwele. Lapho i-thermostat isika ku-compressor ngamahora okusebenza ambalwa kakhulu iyaqalwa. Enye i-compressor izoqala kuphela ngemva kokubambezeleka kwesikhathi esimisiwe, ukuze umthwalo uzohlukaniswa phakathi kwabo. Ukubambezeleka kwesikhathi kunokubaluleka okuphezulu kunezinga lokushisa.

Lapho izinga lokushisa lomoya lehle ngesigamu somehluko i-compressor eyodwa izoma, enye izoqhubeka nokusebenza futhi ingami kuze kufinyelelwe izinga lokushisa elidingekayo.

Ama-compressor asetshenzisiwe kufanele abe uhlobo olukwazi ukuqala ngokumelene nokucindezela okukhulu.

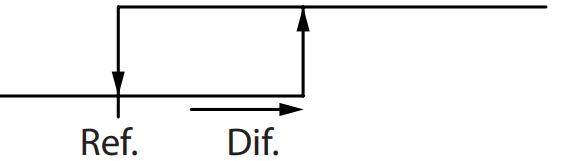

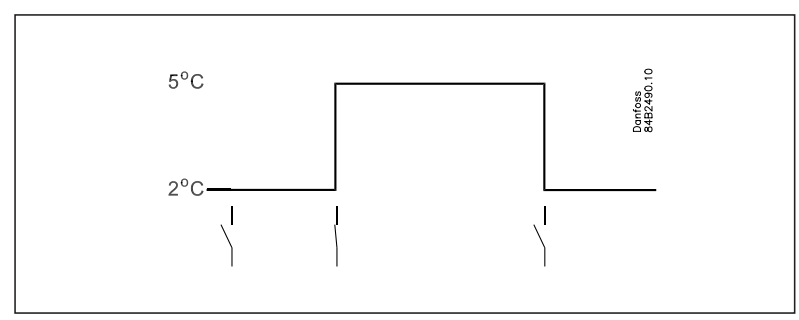

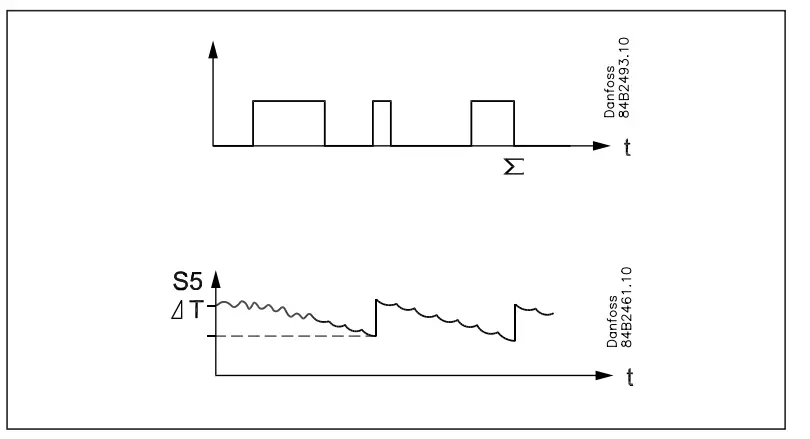

- Ukushintsha kwereferensi yezinga lokushisa

Entweni esetshenziswa ngokungaguquki, ngokwesiboneloample, esetshenziselwa amaqembu emikhiqizo ehlukahlukene. Lapha inkomba yezinga lokushisa ishintshwa kalula ngesignali yokuxhumana kokokufaka kwedijithali. Isignali iphakamisa inani elivamile le-thermostat ngenani elichazwe ngaphambilini. Ngesikhathi esifanayo imikhawulo ye-alamu enenani elifanayo iyasuswa ngokufanele.

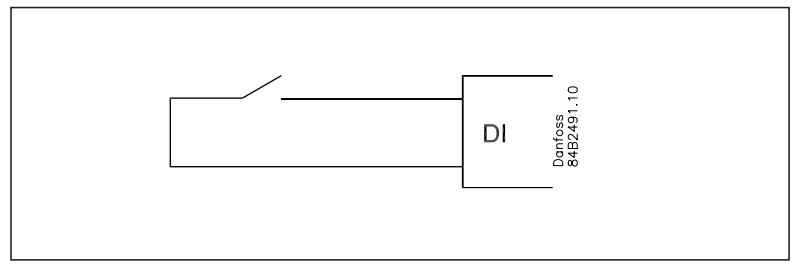

Okokufaka kwedijithali

Kukhona okokufaka kwedijithali okubili kokubili okungasetshenziselwa imisebenzi elandelayo:

- Ukuhlanzwa kwecala

- Umsebenzi wokuxhumana nomnyango nge-alamu

- Ukuqala i-defrost

- I-defrost ehlanganisiwe

- Ukushintsha phakathi kwereferensi yokushisa okubili

- Ukudluliselwa kabusha kwendawo yoxhumana naye ngokuxhumana kwedatha

Umsebenzi wokuhlanza ikesi

Lo msebenzi wenza kube lula ukuqondisa into esebenza esiqandisini ngesigaba sokuhlanza. Ngokuphusha okuthathu kuswishi ushintsha usuka kwesinye isigaba uye kwesinye.

Ukucindezela kokuqala kumisa isiqandisi - abalandeli bayaqhubeka nokusebenza

- "Kamuva": Ukuphusha okulandelayo kumisa abalandeli

- "Kuseza kamuva": Ukucindezela okulandelayo kuqalisa kabusha isiqandisi

Izimo ezihlukene zingalandelwa esibukweni.

Kunethiwekhi i-alamu yokuhlanza idluliselwa kuyunithi yesistimu. Le alamu "ingafakwa" ukuze kunikezwe ubufakazi bokulandelana kwemicimbi.

Umnyango othintana naye umsebenzi

Emakamelweni abandayo nasemagumbini ayisithwathwa iswishi yomnyango ingakhanyisa futhi ivale, iqale futhi imise isiqandisi bese ixwayisa uma umnyango uhlale uvulekile isikhathi eside kakhulu.

I-Defrost

Ngokuya ngohlelo lokusebenza ungakhetha phakathi kwalezi zindlela zokuncibilika ezilandelayo:

- Imvelo: Lapha abalandeli bagcinwa besebenza ngesikhathi sokuncibilika kweqhwa

- Ugesi: Isici sokushisisa siyasebenza

- I-Brine: I-valve igcinwa ivuliwe ukuze amanzi ageleze ageleze ku-evaporator

- I-Hotgas: Lapha ama-valve e-solenoid alawulwa ukuze i-hotgas ikwazi ukugeleza ku-evaporator.

Ukuqala kwe-defrost

I-defrost ingaqalwa ngezindlela ezahlukene

- Isikhawu: I-Defrost iqalwa ngezikhathi ezimisiwe, ake sithi, njalo ngehora lesishiyagalombili

- Isikhathi sesiqandisi:

I-Defrost iqalwa ngezikhathi ezimisiwe zesiqandisi, ngamanye amazwi, isidingo esiphansi sesiqandisi "sizokuhlehlisa" ukuchithwa kweqhwa okuzayo. - Isheduli: Lapha i-defrost ingaqalwa ngezikhathi ezimisiwe zemini nobusuku. Nokho, max. 6 izikhathi

- Othintana naye: I-Defrost iqalwa ngesignali yokuxhumana kokokufaka kwedijithali

- Inethiwekhi: Isiginali yokuncibilika itholwa kuyunithi yesistimu ngokuxhumana kwedatha

- I-S5 temp Kumasistimu angu-1:1 ukusebenza kahle kwe-evaporator kungalandelwa. I-icing-up izoqala ukuncibilika.

- Imanuwali: I-defrost eyengeziwe ingenziwa isebenze kusukela kwenkinobho yesilawuli ephansi kakhulu. (Nakuba kungenjalo isicelo 4).

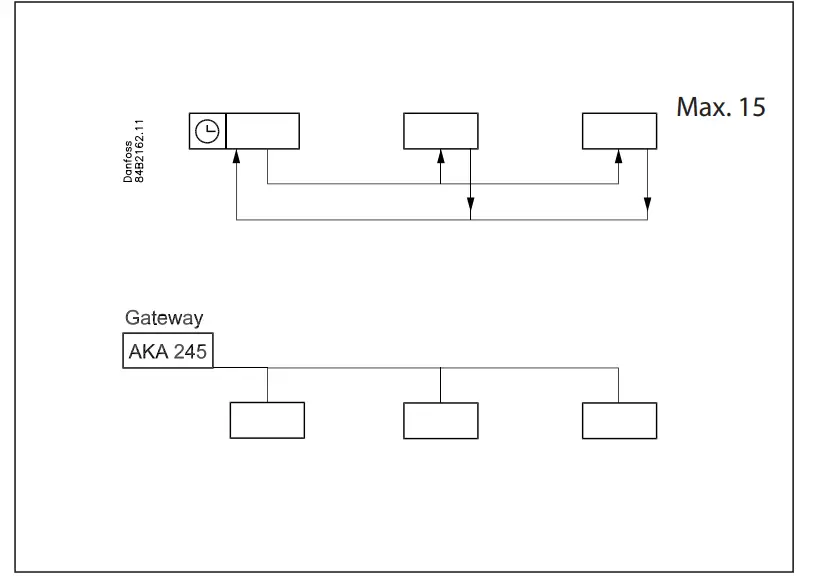

I-defrost ehlanganisiwe

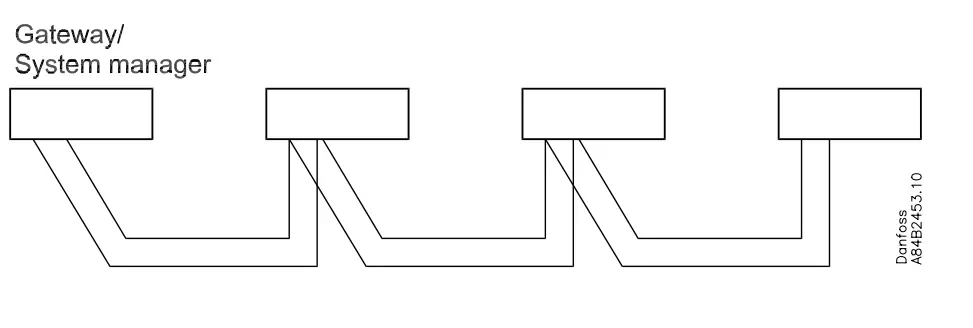

Kunezindlela ezimbili lapho i-defrost ehlanganisiwe ingahlelwa. Kungaba ngoxhumo lwezintambo phakathi kwezilawuli noma ngokuxhumana kwedatha

Ukuxhumeka kwentambo

Esinye sezilawuli sichazwa njengeyunithi yokulawula futhi imojuli yebhethri ingase ifakwe kuyo ukuze iwashi liqiniseke ukuthi liyisipele. Lapho i-defrost iqalwa zonke ezinye izilawuli zizolandela okufanayo futhi ngokufanayo ziqale i-defrost. Ngemva kokuncibilika izilawuli ngazinye zizohamba ziye endaweni yokulinda. Uma bonke sebelindile kuzoba nokushintshwa kwesiqandisi.

(Uma oyedwa eqenjini efuna ukuncibilika, abanye bazolandela okufanayo).

Defrost ngokusebenzisa ukuxhumana kwedatha

Zonke izilawuli zifakwe imojula yokuxhumana kwedatha, futhi ngokukhipha umsebenzi ovela esangweni ukuchithwa kweqhwa kungaxhunyaniswa.

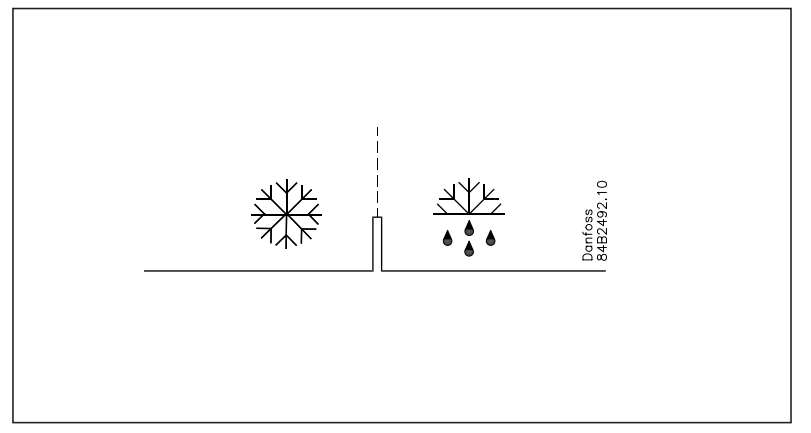

Defrost uma kudingeka

- Ngokusekelwe esikhathini sesiqandisi

Lapho isikhathi sesiqandisi esihlanganisiwe sesidlulile isikhathi esinqunyiwe, i-defrost izoqala.  Ngokusekelwe ezingeni lokushisa

Ngokusekelwe ezingeni lokushisa

Isilawuli sizohlala silandela izinga lokushisa ku-S5. Phakathi kwama-defrosts amabili izinga lokushisa le-S5 lizoba phansi kakhulu lapho i-evaporator ikhuphuka kakhulu (i-compressor isebenza isikhathi eside futhi idonsa izinga lokushisa le-S5 liye phansi). Uma izinga lokushisa lidlula isethi evumelekile ukuhluka kuzoqalwa.

Lo msebenzi ungasebenza kuphela kumasistimu we-1:1

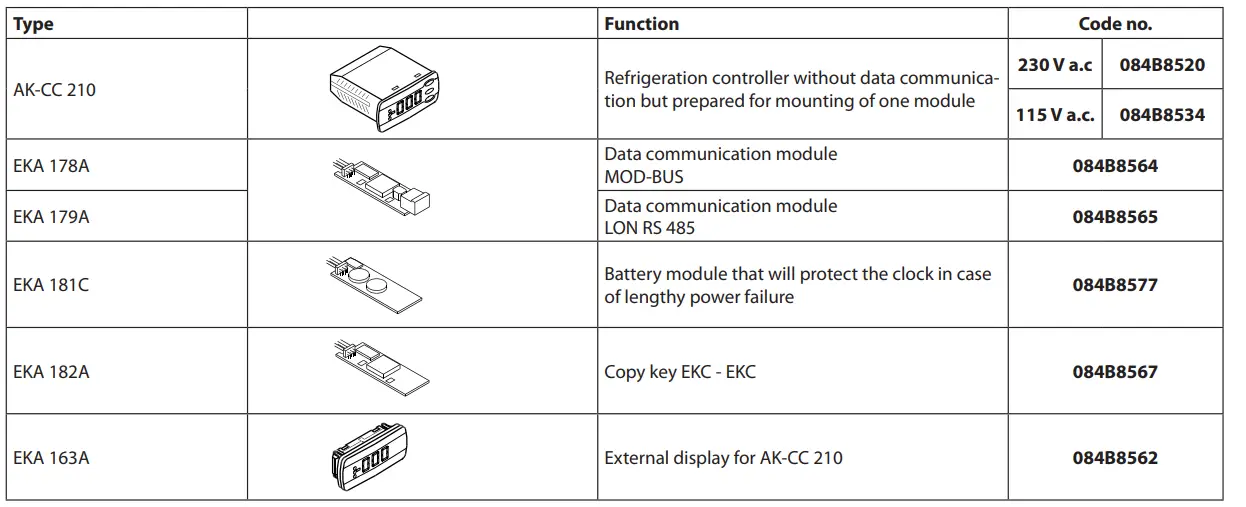

Imojula eyengeziwe

- Ngemva kwalokho isilawuli singafakwa imojuli yokufaka uma uhlelo luyidinga.

Isilawuli silungiswe ngepulaki, ngakho-ke imojula kufanele iphushwe nje- Imodyuli yebhethri

Imojula iqinisekisa ivolumutage kusilawuli uma umthamo wokunikezelatagkufanele ayeke isikhathi esingaphezu kwamahora amane. Ngakho-ke umsebenzi wewashi ungavikelwa ngesikhathi sokuhluleka kwamandla. - Ukuxhumana kwedatha

Uma udinga ukusebenza kwi-PC, imojula yokuxhumana kwedatha kufanele ibekwe kusilawuli.

- Imodyuli yebhethri

- Isibonisi sangaphandle

Uma kudingekile ukukhombisa izinga lokushisa ngaphambili kwento esebenza esiqandisini, uhlobo lokubonisa i-EKA 163A lungafakwa. Isibonisi esengeziwe sizobonisa ulwazi olufanayo nesibonisi sesilawuli, kodwa asibandakanyi izinkinobho zokusebenza. Uma ukusebenza okuvela kusibonisi sangaphandle kudingekile uhlobo lokubonisa i-EKA 164A kufanele lufakwe.

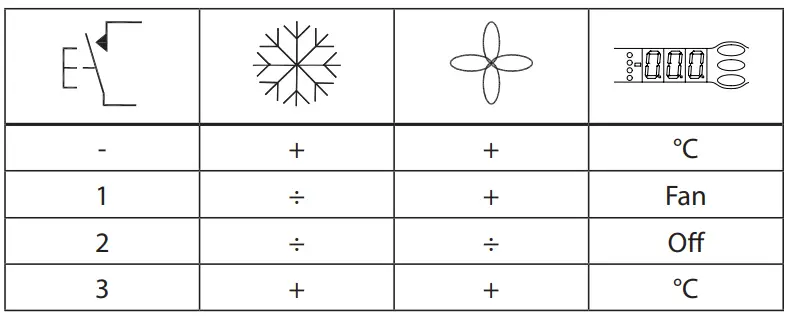

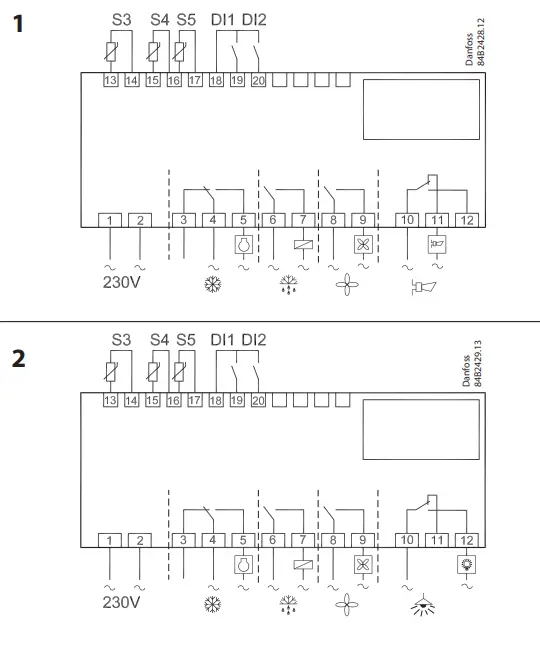

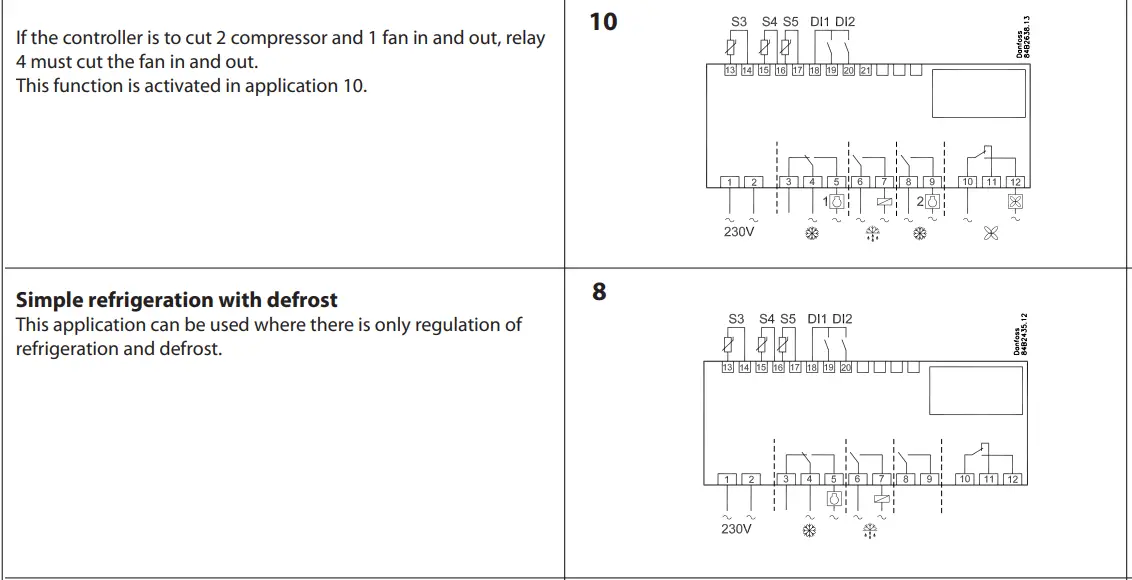

Izinhlelo zokusebenza

Nansi inhlolovo yenkundla yokufakwa kwesicelo yesilawuli.

- Isilungiselelo sizochaza okukhiphayo kokudlulisela ukuze isixhumi esibonakalayo sesilawuli siqondiswe kuhlelo lokusebenza olukhethiwe.

- Ekhasini lama-20 ungabona izilungiselelo ezifanele zemidwebo yezintambo ezifanele.

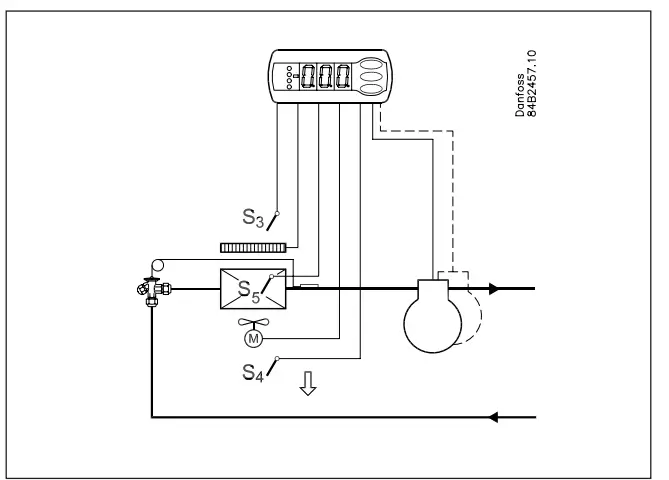

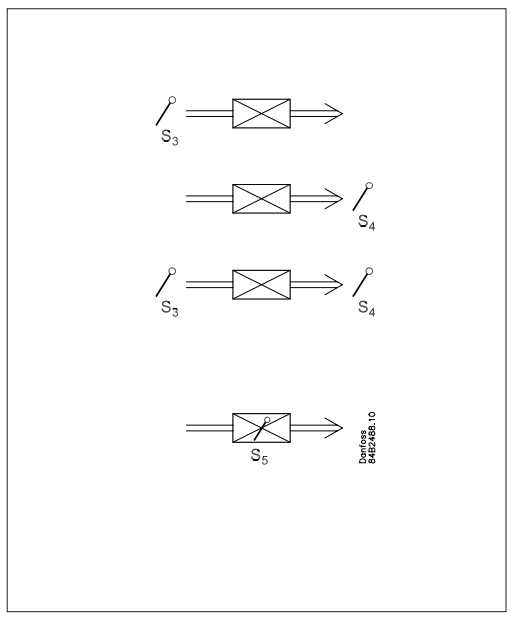

- I-S3 ne-S4 yizinzwa zokushisa. Uhlelo lokusebenza luzonquma ukuthi ngabe izinzwa eyodwa noma enye noma zombili zizosetshenziswa. I-S3 ifakwa ekugelezeni komoya ngaphambi kwe-evaporator. S4 ngemva kwe-evaporator.

- I-percentagIsilungiselelo se-e sizonquma ngokuya ngokuthi ukulawulwa kumele kusekelwe kuphi. I-S5 iyinzwa yokuncibilika futhi ibekwe ku-evaporator.

- I-DI1 kanye ne-DI2 yimisebenzi yokuxhumana engasetshenziswa komunye wale misebenzi elandelayo: umsebenzi womnyango, umsebenzi we-alamu, ukuqala kokuncibilikisa iqhwa, ukushintshwa okuyinhloko kwangaphandle, ukusebenza ebusuku, ukuguqulwa kwereferensi ye-thermostat, ukuhlanzwa komshini, ukufaka isiqandisi ngempoqo noma ukuncibilika kweqhwa okuhlanganisiwe. Bona imisebenzi kumasethingi o02 kanye no-o37.

Ukulawula isiqandisi nge-compressor eyodwa

Imisebenzi ijwayelane nezinhlelo ezincane zesiqandisi okungenzeka kube izinto ezisebenza esiqandisini noma amagumbi abandayo.

Ama-relay amathathu angakwazi ukulawula isiqandisi, i-defrost namafeni, futhi i-relay yesine ingasetshenziselwa umsebenzi we-alamu, ukulawula ukukhanya noma ukulawula ukushisa kwesitimela.

- Umsebenzi we-alamu ungaxhunyaniswa nomsebenzi wokuxhumana ovela kuswishi yomnyango. Uma umnyango uhlala uvuliwe isikhathi eside kunesivunyelwe kuzoba khona i-alamu.

- Isilawuli sokukhanya singabuye sixhunywe nomsebenzi wokuxhumana ovela kuswishi yomnyango. Isicabha esivulekile sizokhanyisa isibani futhi sizohlala sikhanyisiwe imizuzu emibili ngemva kokuba umnyango usuvaliwe futhi.

- Umsebenzi wokushisa ujantshi ungasetshenziswa esiqandisini noma ezintweni zikagesi eziqandisayo noma endaweni yokushisa yomnyango emakamelweni ayisithwathwa.

Amafeni angamiswa ngesikhathi sokuncibilika futhi angalandela nokuvula/ukuvala kwesimo sesicabha.

Kuneminye imisebenzi eminingana yomsebenzi we-alamu kanye nokulawula ukukhanya, ukulawula ukushisa kukaloliwe namafeni. Sicela ubheke izilungiselelo ezifanele.

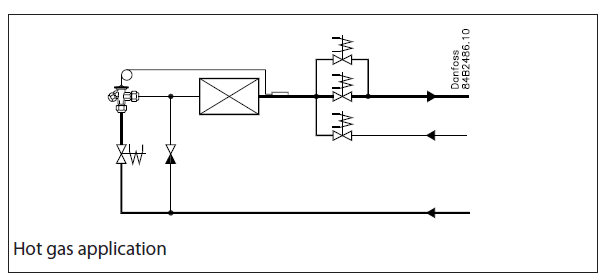

I-Hot gas defrost

I-Hot gas defrost

Lolu hlobo lokuxhuma lungasetshenziswa kumasistimu ane-hotgas defrost, kodwa kuphela kumasistimu amancane, athi, ezitolo ezinkulu - okuqukethwe okusebenzayo akuzange kushintshwe kumasistimu anezindleko ezinkulu. Umsebenzi wokushintsha we-Relay 1 ungasetshenziswa ivalvu yokudlula kanye/noma i-hotgas valve.

I-Relay 2 isetshenziselwa isiqandisi.

Inhlolovo yemisebenzi

| Umsebenzi | Ipharamitha | Ipharamitha ngokusebenza ngokuxhumana kwedatha |

| Isibonisi esijwayelekile | ||

| Ngokuvamile izinga lokushisa elivela kwenye yezinzwa ze-thermostat ezimbili i-S3 noma i-S4 noma ingxube yezilinganiso ezimbili iyaboniswa.

Ku-o17 isilinganiso sinqunywa. |

Bonisa umoya (u56) | |

| I-Thermostat | Ukulawula i-thermostat | |

| Setha iphuzu

Umthethonqubo usekelwe kunani elimisiwe kanye nokusuka endaweni, uma kusebenza. Inani lisethwa ngokucindezela inkinobho ephakathi. Inani elimisiwe lingakhiywa noma lilinganiselwe kububanzi ngezilungiselelo eziku-r02 kanye no-r 03. Isithenjwa noma nini singabonwa kokuthi ”u28 Temp. ref” |

Ukusika °C | |

| Umehluko

Uma izinga lokushisa lingaphezulu kwereferensi + umehluko obekiwe, i-com-pressor relay izosikwa phakathi. Izonqamuka futhi lapho izinga lokushisa lehla kunkomba emisiwe. |

r01 | Umehluko |

| Umkhawulo wephoyinti

Ibanga lesilungiselelo sesilawuli sephoyinti lokubeka lingase lincishiswe, ukuze amanani aphezulu kakhulu noma aphansi kakhulu angasethwa ngephutha - kube nomonakalo owumphumela. |

||

| Ukuze ugweme ukusetha okuphezulu kakhulu kwe-setpoint, ubuningi. inani lereferensi elivumelekile kufanele lehliswe. | r02 | Ukusika okuphezulu °C |

| Ukuze ugweme ukusetha okuphansi kakhulu kwe-setpoint, i-min. inani lereferensi elivumelekile kufanele lenyuswe. | r03 | Ukusika okuncane °C |

| Ukulungiswa kwezinga lokushisa lesibonisi

Uma izinga lokushisa emikhiqizweni kanye nezinga lokushisa elitholwe isilawuli kungafani, ukulungiswa kwe-offset kwezinga lokushisa elibonisiwe kungenziwa. |

r04 | I-Disp. I-Adj. K |

| Iyunithi yezinga lokushisa

Setha lapha uma isilawuli sizobonisa amanani okushisa ku-°C noma ku-°F. |

r05 | Temp. iyunithi

°C=0. / °F=1 (U-°C kuphela ku-AKM, kungakhathaliseki ukuthi isiphi isilungiselelo) |

| Ukulungiswa kwesiginali kusuka ku-S4

Ukunxeshezelwa okungenzeka ngekhebula lenzwa ende |

r09 | Lungisa i-S4 |

| Ukulungiswa kwesiginali kusuka ku-S3

Ukunxeshezelwa okungenzeka ngekhebula lenzwa ende |

r10 | Lungisa i-S3 |

| Qala / stop of esiqandisini

Ngalesi silungiselelo isiqandisi singaqalwa, simiswe noma ukukhipha mathupha kokuphumayo kungavunyelwa. Ukuqala / ukumiswa kwesiqandisi nakho kungafezwa ngomsebenzi wokushintsha wangaphandle oxhunywe kokokufaka kwe-DI. Isiqandisi esimisiwe sizonikeza "i-alamu yokulinda". |

r12 | Ukushintsha Okuyinhloko

1: Qala 0: Yima -1: Ukulawula okwenziwa ngesandla kokuphumayo kuvunyelwe |

| Inani lokubuyisela emuva ebusuku

Ireferensi ye-thermostat izoba i-setpoint kanye nalelivelu lapho isilawuli sishintsha sisebenza ebusuku. (Khetha inani elingalungile uma kuzoba nokuqongelela okubandayo.) |

r13 | I-offset yasebusuku |

| Ukukhethwa kwenzwa ye-thermostat

Lapha uchaza inzwa i-thermostat ezoyisebenzisela umsebenzi wayo wokulawula. S3, S4, noma inhlanganisela yazo. Ngokusetha u-0%, kusetshenziswa i-S3 kuphela (Isono). Ngo-100%, i-S4 kuphela. (Ngohlelo lokusebenza 9 kufanele kusetshenziswe inzwa ye-S3) |

r15 | Ther. S4 % |

| Umsebenzi wokushisa

Umsebenzi usebenzisa isici sokushisisa somsebenzi we-defrost ukunyusa izinga lokushisa. Umsebenzi uqala ukusebenza ngenani lamadigri (r36) ngaphansi kwereferensi yangempela bese usika futhi ngokuhluka kwamadigri angu-2. Ukulawulwa kwenziwa ngesignali engu-100% evela kunzwa ye-S3. Amafeni azobe esebenza uma kunesifudumezi. Amafeni kanye nomsebenzi wokushisa uzoyeka uma umsebenzi womnyango ukhethiwe futhi umnyango uvuliwe. Lapho lo msebenzi usetshenziswa khona i-cutout yangaphandle yokuphepha kufanele futhi ifakwe, ukuze ukushisa okuphezulu kwesici sokushisa kungenzeki. Khumbula ukusetha i-D01 ku-defrosting kagesi. |

r36 | I-HeatStartRel |

| Ukwenza kusebenze ukususwa kwereferensi

Uma umsebenzi ushintshwa ukuze uthi ON ireferensi ye-thermostat izokhishwa ivelu elingu-r40. Ukuqalisa kungase futhi kwenzeke ngokufaka i-DI1 noma i-DI2 (echazwe ngo-o02 noma o37). |

r39 | Th. offset |

| Inani lokususwa kwereferensi

Ireferensi ye-thermostat namanani e-alamu ahanjiswa ngenani elilandelayo lamadigri lapho ukususwa kwenziwa kusebenze. Ukusebenza kungenziwa nge-r39 noma nge-put DI |

r40 | Th. susa K |

| I-setbck yasebusuku (ukuqala kwesiginali yasebusuku) | ||

| Kuphole ngenkani.

(ukuqala kokupholisa ngempoqo) |

||

| I-alamu | Izilungiselelo ze-alamu | |

| Isilawuli singanikeza i-alamu ezimeni ezahlukene. Uma kune-alamu wonke ama-light-emitting diode (LED) azokhanyisa kuphaneli yangaphambili yesilawuli, futhi i-alamu izonqamuka. | Ngokuxhumana kwedatha ukubaluleka kwama-alamu ngamanye kungachazwa. Ukusetha kwenziwa kumenyu "yezindawo ze-alamu". | |

| Ukubambezeleka kwe-alamu (ukubambezeleka kwe-alamu okufushane)

Uma eyodwa kwamanani amabili omkhawulo yeqiwe, umsebenzi wesibali sikhathi uzoqala. I-alamu ngeke isebenze kuze kudlule ukulibaziseka kwesikhathi esimisiwe. Ukubambezeleka kwesikhathi kusethwe ngamaminithi. |

A03 | Ukubambezeleka kwe-alamu |

| Ukubambezeleka kwesikhathi kwe-alamu yomnyango

Ukubambezeleka kwesikhathi kusethwe ngamaminithi. Umsebenzi uchazwa ku-o02 noma ku-o37. |

A04 | I-DoorOpen del |

| Ukulibaziseka kwesikhathi sokupholisa (ukubambezeleka okude kwe-alamu)

Lesi sikhathi sokulibaziseka sisetshenziswa ngesikhathi sokuqala, ngesikhathi sokuncibilika, ngokushesha ngemva kokumiswa kweqhwa. Kuzoba noshintsho ekubambezelekeni kwesikhathi esijwayelekile (A03) uma izinga lokushisa lehlile ngaphansi komkhawulo we-alamu omisiwe. Ukubambezeleka kwesikhathi kusethwe ngamaminithi. |

A12 | Donsela phansi del |

| Umkhawulo we-alamu ophezulu

Lapha usetha ukuthi i-alamu yezinga lokushisa eliphezulu izoqala nini. Inani eliwumkhawulo lisethwe ku-°C (inani eliphelele). Inani elilinganiselwe lizokhushulwa phakathi nokusebenza ebusuku. Inani liyafana nalelo elimiselwe ukubuyisela emuva ebusuku, kodwa lizokhushulwa kuphela uma inani liphozithivu. Inani elilinganiselwe lizophinde liphakanyiswe mayelana nokugudluzwa kwereferensi u-r39. |

A13 | I-HighLim Air |

| Umkhawulo we-alamu ophansi

Lapha usetha ukuthi i-alamu yezinga lokushisa eliphansi izoqala nini. Inani eliwumkhawulo lisethwe ku-°C (inani eliphelele). Inani elilinganiselwe lizophinde liphakanyiswe mayelana nokugudluzwa kwereferensi u-r39. |

A14 | I-LowLim Air |

| Ukubambezeleka kwe-alamu ye-DI1

Okokufaka kokusika/ukusika kuzoholela ku-alamu lapho ukubambezeleka kwesikhathi sekudlulile. Umsebenzi uchazwa ku-o02. |

A27 | I-AI.Libazisa i-DI1 |

| Ukubambezeleka kwe-alamu ye-DI2

Okokufaka kokusika/okusika kuzoholela ku-alamu lapho ukubambezeleka kwesikhathi sekudlulile. Umsebenzi uchazwa ku-o37 |

A28 | I-AI.Libazisa i-DI2 |

| Isignali ye-alamu thermostat

Lapha kufanele uchaze isilinganiso phakathi kwezinzwa okufanele zisetshenziswe i-alamu ye-thermostat. S3, S4 noma inhlanganisela yakho kokubili. Ngokusetha u-0% kuphela i-S3 isetshenziswa. Ngo-100% kuphela i-S4 isetshenziswa |

A36 | I-alamu S4% |

| Setha kabusha i-alamu | ||

| Iphutha le-EKC |

| I-Compressor | Ukulawula i-Compressor | |

| I-compressor relay isebenza ngokubambisana ne-thermostat. Lapho i-thermostat ibiza isiqandisi kuzosebenza ukuhanjiswa kwe-compressor. | ||

| Izikhathi zokugijima

Ukuze uvimbele ukusebenza okungajwayelekile, amanani angasethwa ngesikhathi okufanele i-compressor isebenze uma isiqalile. Futhi kufanele kumiswe isikhathi esingakanani okungenani. Izikhathi zokusebenza azibonwa lapho ama-defrosts eqala. |

||

| Okuncane. NGESIKHATHI (ngamaminithi) | c01 | Okuncane. Ngesikhathi |

| Okuncane. I-OFF-time (ngamaminithi) | c02 | Okuncane. Isikhathi sokuphumula |

| Ukulibaziseka kwesikhathi sokuhlanganisa ama-compressor amabili

Izilungiselelo zibonisa isikhathi okufanele sidlule kusukela ekusikelweni kokudlulisela phambili futhi kuze kube yilapho i-relay elandelayo kufanele ingene. |

c05 | Ukubambezeleka kwesinyathelo |

| Umsebenzi odluliselwe emuva obuyiselwe emuva we-D01

0: Umsebenzi ojwayelekile lapho i-relay inqamula lapho isiqandisi sifunwa 1: Umsebenzi ohlehlisiwe lapho i-relay inqamuka lapho isiqandisi sifunwa (le ntambo ikhiqiza umphumela wokuthi kuzoba nesiqandisi uma amandlatage kusilawuli sehlulekile). |

c30 | I-Cmp edluliselwe NC |

| I-LED engaphambili kwesilawuli izobonisa ukuthi isiqandisi siyaqhubeka yini. | I-Compa Relay

Lapha ungafunda isimo se-compressor relay, noma ungaphoqelela ukulawula ukudluliswa kwe-relay kumodi "Yokulawula ngesandla" |

|

| I-Defrost | Ukulawula i-Defrost | |

|

||

Indlela ye-Defrost

|

d01 | Def. indlela 0 = non

1 = El 2 = Igesi 3= Ubisi |

| Defrost stop lokushisa

I-defrost imiswa ezingeni lokushisa elinikeziwe elilinganiswa ngenzwa (inzwa ichazwa ku-d10). Inani lokushisa lisethiwe. |

d02 | Def. Misa iTemp |

Isikhawu phakathi kokuqala kwe-defrost

|

d03 | Isikhawu se-Def (0=off) |

| Ubukhulu. ubude be-defrost

Lesi silungiselelo yisikhathi sokuphepha ukuze ukuncibilika kumiswe uma bekungakaze kube khona ukuma okusekelwe ezingeni lokushisa noma ngokumiswa kweqhwa okuhlanganisiwe. |

d04 | I-Max Def. isikhathi |

Isikhathi stagi-gering ye-defrost cut in ngesikhathi sokuqala

|

d05 | Isikhathi Stagg. |

| Isikhathi sokuphumula

Lapha usetha isikhathi okumele sidlule kusukela ekuncipheni futhi kuze kube yilapho i-compressor iqala futhi. (Isikhathi lapho amanzi econsa ku-evaporator). |

d06 | Isikhathi se-DripOff |

| Ukubambezeleka kwefeni kuqala ngemva kokumiswa kwesithwathwa

Lapha usetha isikhathi okumele sidlule kusukela ekuqaleni kwe-compressor ngemva kokumiswa kweqhwa kuze kube yilapho isiphephetha-moya siqala futhi. (Isikhathi lapho amanzi “eboshelwa” ku-evaporator). |

d07 | I-FanStartDel |

| Izinga lokushisa lokuqala labalandeli

I-fan ingase futhi iqalwe ngaphambi kwesikhathi kunalokho kushiwo ngaphansi kokuthi "Ukubambezeleka kokuqala kwabalandeli ngemva kokumiswa kweqhwa", uma inzwa ye-defrost S5 ibhalisa inani eliphansi kunaleli elibekwe lapha. |

d08 | I-FanStartTemp |

| I-fan inqamule ngesikhathi sokushisa

Lapha ungasetha ukuthi ingabe ifeni kufanele isebenze ngesikhathi sokumiswa kweqhwa. 0: Imisiwe (Igijima ngesikhathi sokupompa phansi)

|

d09 | FanDuringDef |

| Inzwa ye-Defrost

Lapha uchaza inzwa ye-defrost. 0: Akukho, i-defrost isekelwe esikhathini 1: S5 2: S4 |

d10 | I-DefStopSens. |

| Ukulibaziseka kwe-Pumpdown

Setha isikhathi lapho i-evaporator ithululwa khona esiqandisini ngaphambi kokuncibilika. |

d16 | Phumpu dwn del. |

| Ukulibaziseka kokukhipha amanzi (kuphela mayelana ne-hotgas)

Setha isikhathi lapho i-evaporator ithululwa khona kusiqandisi esijiyile ngemva kokumiswa kweqhwa. |

d17 | I-Drain del |

| I-Defrost ngokufunwa - isikhathi sesiqandisi esihlanganisiwe

Setha lapha isikhathi sesiqandisi esivunyelwe ngaphandle kwama-defrosts. Uma isikhathi sesidlulile, i-defrost izoqala. Ngokusethwa = 0 umsebenzi uyasikwa. |

d18 | I-MaxTherRunT |

| Defrost uma kudingeka - izinga lokushisa le-S5

Isilawuli sizolandela ukusebenza kwe-evaporator, futhi ngokubala kwangaphakathi nezilinganiso zezinga lokushisa le-S5 sizokwazi ukuqalisa ukuncibilika lapho ukuhluka kwezinga lokushisa kwe-S5 kuba kukhulu kunalokho okudingekayo. Lapha usetha ukuthi isilayidi sezinga lokushisa le-S5 sikhulu kangakanani esingavunyelwa. Uma inani lidluliswa, i-defrost izoqala. Umsebenzi ungasetshenziswa kuphela ezinhlelweni ze-1:1 lapho izinga lokushisa elihwamukayo lizoba phansi ukuze kuqinisekiswe ukuthi izinga lokushisa lomoya lizogcinwa. Ezinhlelweni ezimaphakathi umsebenzi kumele unqanyulwe. Ngokusethwa = 20 umsebenzi uyasikwa |

d19 | I-CutoutS5Dif. |

| Ukubambezeleka komjovo wegesi eshisayo

Ingasetshenziswa uma kusetshenziswa ama-vale ohlobo lwe-PMLX ne-GPLX. Isikhathi sisethwe ukuze i-valve ivalwe ngokuphelele ngaphambi kokuba igesi eshisayo ivulwe. |

d23 | — |

| Uma ufisa ukubona izinga lokushisa kusizwa sokumisa iqhwa, cindezela inkinobho yesilawuli ephansi kakhulu. | I-Defrost temp. | |

| Uma ufisa ukuqalisa i-defrost eyengeziwe, cindezela inkinobho yesilawuli ephansi kakhulu imizuzwana emine.

Ungamisa i-defrost eqhubekayo ngendlela efanayo |

Def Qala

Lapha ungaqala i-defrost eyenziwa ngesandla |

|

| I-LED engaphambili kwesilawuli izokhombisa ukuthi ngabe i-defrost iyaqhubeka. | I-Defrost Relay

Lapha ungafunda isimo se-relay ye-defrost noma ungaphoqa-ukulawula ukudluliselwa kumodi "Yokulawula mathupha". |

|

| Bamba Ngemva kweDef

Ibonisa VULIWE lapho isilawuli sisebenza ngokuncibilika okuhlanganisiwe. |

||

| Defrost State Status on defrost

1= phompa phansi / ncibilikisa |

||

| Umlandeli | Ukulawula abalandeli | |

| Ifeni ime ku-compressor esikiwe

Lapha ungakhetha ukuthi ingabe ifeni izomiswa yini uma i-compressor inqanyulwa |

F01 | Isitobhi sabalandeli CO

(Yebo = Umlandeli umile) |

| Ukubambezeleka kokuma kwefeni lapho i-compressor inqanyulwa

Uma ukhethe ukumisa isiphephetha-moya lapho i-compressor inqanyulwa, ungabambezela ukuma kwefeni lapho i-compressor iyekile. Lapha ungasetha ukubambezeleka kwesikhathi. |

F02 | Umlandeli del. CO |

| Izinga lokushisa lokumisa abalandeli

Umsebenzi umisa abalandeli esimweni sephutha, ukuze bangakwazi ukunikeza amandla kumshini. Uma inzwa ye-defrost ibhalisa izinga lokushisa eliphezulu kunaleli elibekwe lapha, abalandeli bazomiswa. Kuzoba nokuqalwa kabusha kokuthi 2 K ngaphansi kwesilungiselelo. Umsebenzi awusebenzi ngesikhathi sokumiswa kweqhwa noma ukuqalisa ngemva kokumiswa kweqhwa. Ngokusetha +50°C umsebenzi uyaphazamiseka. |

F04 | I-FanStopTemp. |

| I-LED ngaphambili kwesilawuli izokhombisa ukuthi ifeni iyasebenza yini. | Ukudluliswa kwabalandeli

Lapha ungafunda isimo se-relay yabalandeli, noma uphoqelele ukulawula i-relay kumodi "Yokulawula mathupha". |

| I-HACCP | I-HACCP | |

| Izinga lokushisa le-HACCP

Lapha ungabona isilinganiso sezinga lokushisa esidlulisela isignali kumsebenzi |

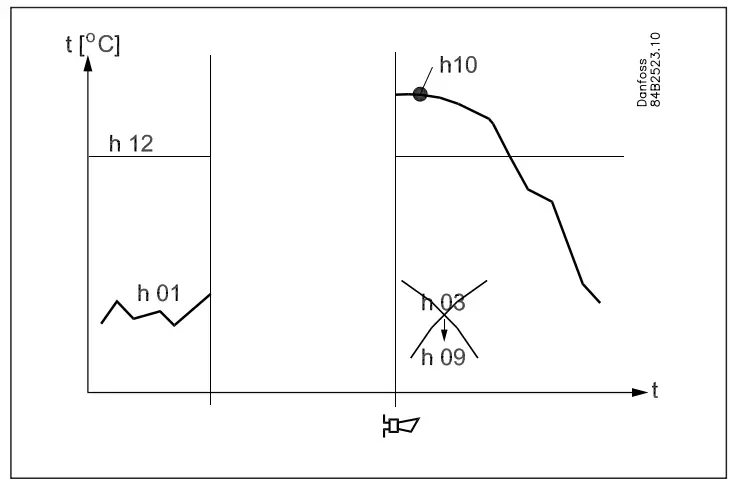

h01 | Izinga lokushisa le-HACCP |

| Okokugcina izinga lokushisa eliphakeme kakhulu le-HACCP labhaliswa mayelana nalokhu: (Inani lingafundwa).

H01: Izinga lokushisa elidlula ngesikhathi somthethonqubo ojwayelekile. H02: Izinga lokushisa elidlula ngesikhathi sokuhluleka kwamandla. Isipele sebhethri silawula izikhathi. H03: Izinga lokushisa elidlula ngesikhathi sokuhluleka kwamandla. Akukho ukulawula izikhathi. |

h02 | – |

| Okokugcina izinga lokushisa le-HACCP leqiwe: Unyaka | h03 | – |

| Okokugcina izinga lokushisa le-HACCP lidluliwe: Inyanga | h04 | – |

| Okokugcina izinga lokushisa le-HACCP leqiwe: Usuku | h05 | – |

| Okokugcina izinga lokushisa le-HACCP lidluliwe: Ihora | h06 | – |

| Okokugcina izinga lokushisa le-HACCP leqiwe: Iminithi | h07 | – |

| Kugcine ukudlula: Ubude besikhathi ngamahora | h08 | – |

| Kugcine ukudlula: Ubude besikhathi ngamaminithi | h09 | – |

| Izinga lokushisa eliphakeme

Izinga lokushisa eliphakeme kakhulu elikalwe lizolondolozwa ngokuqhubekayo lapho izinga lokushisa lidlula inani elilinganiselwe ku-h12. Inani lingafundwa kuze kube yisikhathi esilandelayo lapho izinga lokushisa lidlula inani elilinganiselwe. Ngemva kwalokho ibhalwa phezu kwezilinganiso ezintsha. |

h10 | Isilinganiso esiphezulu. |

| Ukukhethwa komsebenzi 0: Awukho umsebenzi we-HACCP

1: I-S3 kanye/noma i-S4 esetshenziswa njengenzwa. Incazelo yenzeka ngo-h14. 2: I-S5 isetshenziswe njengenzwa. |

h11 | Inzwa ye-HACCP |

| Umkhawulo we-alamu

Lapha usetha inani lokushisa lapho umsebenzi we-HACCP uzosebenza khona. Uma inani liba phezulu kunesethi, ukubambezeleka kwesikhathi kuyaqala. |

h12 | Umkhawulo we-HACCP |

| Ukubambezeleka kwesikhathi kwe-alamu (kuphela ngesikhathi somthethonqubo ojwayelekile). Uma ukubambezeleka kwesikhathi sesidlulile i-alamu iyacushwa. | h13 | Ukubambezeleka kwe-HACCP |

| Ukukhethwa kwezinzwa zokulinganisa

Uma inzwa ye-S4 kanye/noma inzwa ye-S3 isetshenziswa, isilinganiso phakathi kwazo kufanele isethwe. Ekusetheni u-100% kuphela i-S4 isetshenziswa. Lapho kulungiselelwa u-0% kuphela kusetshenziswa i-S3. |

h14 | I-HACCP S4% |

| Umsebenzi we-defrosting wangaphakathi/iwashi | ||

| (Ayisetshenziswa uma ishejuli yokuqeda isithwathwa yangaphandle isetshenziswa ngokuxhumana kwedatha.) Kungasethwa izikhathi ezingafika kweziyisithupha ukuze kuqalwe iqhwa usuku lonke. | ||

| Ukuqala kwe-Defrost, ukulungiselelwa kwehora | t01-t06 | |

| Isiqalo sokuncibilika, ukulungiselelwa kweminithi (1 no-11 kuhlangene, njll.) Uma konke okuthi t01 kuya ku-t16 kulingana no-0 iwashi ngeke liqale ukuncibilika. | t11-t16 | |

| Iwashi lesikhathi sangempela

Ukusetha iwashi kuyadingeka kuphela uma kungekho ukuxhumana kwedatha. Uma kwenzeka ukwehluleka kwamandla okungaphansi kwamahora amane, umsebenzi wewashi uzogcinwa. Uma ukhweza imojuli yebhethri umsebenzi wewashi ungagcinwa isikhathi eside. Kukhona futhi inkomba yedethi esetshenziselwa ukubhaliswa kwezilinganiso zokushisa. |

||

| Iwashi: Ukulungiselelwa kwehora | t07 | |

| Iwashi: Ukulungiselelwa kwemizuzu | t08 | |

| Iwashi: Ukulungiselelwa kosuku | t45 | |

| Iwashi: Ukulungiselelwa kwenyanga | t46 | |

| Iwashi: Ukulungiselelwa konyaka | t47 | |

| Okunhlobonhlobo | Okunhlobonhlobo | |

| Ukubambezeleka kwesignali yokuphumayo ngemva kokuqala

Ukuqalisa ngemva kokuhluleka kwamandla imisebenzi yesilawuli ingase ibambezeleke ukuze ukulayishwa ngokweqile kwenethiwekhi yokuphakela ugesi kugwenywe. Lapha ungasetha ukubambezeleka kwesikhathi. |

o01 | I-DelayOfOutp. |

| Isiginali yokufaka yedijithali – DI1

Isilawuli sinokufaka kwedijithali 1 okungasetshenziselwa omunye wale misebenzi elandelayo: Valiwe: Okokufaka akusetshenzisiwe

|

o02 | I-DI 1 Config.

Incazelo yenzeka ngenani eliyinombolo elikhonjiswe kwesokunxele.

(0 = ivaliwe)

Isimo se-DI (Isilinganiso) Isimo samanje sokokufaka kwe-DI siboniswa lapha. VULIWE noma VALIWE. |

|

Ngemva kokufakwa kwemojuli yokuxhumana ngedatha isilawuli singasetshenzwa ngokulingana nezinye izilawuli kuzilawuli zesiqandisi ze-ADAP-KOOL®. | |

| o03 | ||

| o04 | ||

| Ikhodi yokufinyelela 1 (Ukufinyelela kuzo zonke izilungiselelo)

Uma izilungiselelo kusilawuli zizovikelwa ngekhodi yokufinyelela ungasetha inani lenombolo phakathi kuka-0 no-100. Uma kungenjalo, ungakhansela umsebenzi ngokusetha u-0. (I-99 izohlala ikunikeza ukufinyelela). |

o05 | – |

| Uhlobo lwenzwa

Ngokuvamile kusetshenziswa inzwa ye-Pt 1000 enokunemba kwesignali enkulu. Kodwa ungasebenzisa futhi inzwa ngenye ukunemba kwesignali. Lokho kungase kube inzwa ye-PTC 1000 (1000 ohm) noma inzwa ye-NTC (5000 Ohm ku-25°C). Zonke izinzwa ezifakiwe kufanele zibe zohlobo olufanayo. |

o06 | I-SensorConfig Pt = 0

I-PTC = 1 I-NTC = 2 |

| Bonisa isinyathelo

Yebo: Inikeza izinyathelo zika-0.5° Cha: Inikeza izinyathelo zika-0.1° |

o15 | I-Disp. Isinyathelo = 0.5 |

| Ubukhulu. isikhathi sokulinda ngemva kokuhlanganiswa kwe-defrost

Uma isilawuli sesiqedile ukuncibilika sizolinda isignali etshela ukuthi isiqandisi singaqaliswa kabusha. Uma lesi siginali yehluleka ukuvela ngesizathu esisodwa noma esinye, isilawuli ngokwaso sizoqala isiqandisi uma lesi sikhathi sokulinda sesidlulile. |

o16 | I-Max HoldTime |

| Khetha isiginali yesibonisi S4%

Lapha uchaza isignali ezoboniswa yisibonisi. S3, S4, noma inhlanganisela yakho kokubili. Ngokusetha u-0% kuphela i-S3 isetshenziswa. Nge-100% kuphela i-S4. |

o17 | I-Disp. S4% |

| Isiginali yokufaka yedijithali – D2

Isilawuli sinokufaka kwedijithali 2 okungasetshenziselwa omunye wale misebenzi elandelayo: Valiwe: Okokufaka akusetshenzisiwe.

|

o37 | I-DI2 config. |

Ukucushwa komsebenzi wokukhanya (dlulisa oku-4 ezinhlelweni 2 no-6)

|

o38 | Ukulungisa ukukhanya |

| Ukwenza kusebenze i-relay yokukhanya

I-relay yokukhanya ingenziwa isebenze lapha, kodwa kuphela uma ichazwe ku-o38 ngokusetha 2. |

o39 | Isilawuli kude esikhanyayo |

| Ukushisa kwesitimela phakathi nokusebenza kwansuku zonke

Isikhathi se-ON sisethwe njengephesentitage yesikhathi |

o41 | Railh.ON usuku% |

| Ukushisa kukaloliwe phakathi nokusebenza ebusuku

Isikhathi se-ON sisethwe njengephesentitage yesikhathi |

o42 | Railh.ON ngt% |

| Umjikelezo wokushisa ujantshi

Isikhathi se-aggregate ISIKHATHI SESIKHATHI + nesikhathi sokuvala sisethwe ngamaminithi |

o43 | Railh. umjikelezo |

Ukuhlanzwa kwecala

Uma umsebenzi ulawulwa isignali kokokufaka kwe-DI1 noma kwe-DI2, isimo esifanelekile singabonakala lapha kumenyu. |

o46 | Ikesi lihlanzekile |

| Ukukhethwa kwesicelo

Isilawuli singachazwa ngezindlela ezihlukahlukene. Lapha ubeka ukuthi yiziphi izicelo eziyi-10 ezidingekayo. Ekhasini lesi-6 ungabona ucwaningo lwezinhlelo zokusebenza. Le menyu ingasethwa kuphela uma ukulawulwa kumisiwe, okungukuthi “r12” isethwe ku-0. |

o61 | - I-Appl. Imodi (okukhiphayo kuphela ku-Danfoss kuphela) |

| Dlulisela isethi yokusetha ngaphambilini kusilawuli

Kungenzeka ukukhetha ukulungiselelwa okusheshayo kwenani lamapharamitha. Kuya ngokuthi uhlelo lokusebenza noma igumbi kufanele lilawulwe kanye nokuthi ukucwiliswa kwesithwathwa kuzomiswa ngokuya kwesikhathi noma ngokuya ngezinga lokushisa. Inhlolovo ingabonwa ekhasini 22. Le menyu ingasethwa kuphela uma ukulawulwa kumisiwe, okungukuthi “r12” isethwe ku-0.

Ngemva kokusetha inani lizobuyela ku-0. Noma yikuphi ukulungiswa/ukusetha okulandelayo kwamapharamitha kungenziwa, njengoba kudingekile. |

o62 | – |

| Ikhodi yokufinyelela 2 (Ukufinyelela ekulungiseni)

Kukhona ukufinyelela ekulungisweni kwamanani, kodwa hhayi kuzilungiselelo zokumisa. Uma izilungiselelo kusilawuli kufanele zivikelwe ngekhodi yokungena ungasetha inani lenombolo phakathi kuka-0 no-100. Uma kungenjalo, ungakhansela uhlelo ngokusetha u-0. Uma uhlelo lusetshenziswa, ikhodi yokungena 1 (o05) kufanele futhi kusetshenziswe. |

o64 | – |

| Kopisha izilungiselelo zamanje zesilawuli

Ngalo msebenzi izilungiselelo zesilawuli zingadluliselwa kukhiye wokuhlela. Ukhiye ungaqukatha amasethi ahlukene angafika kwangu-25. Khetha inombolo. Zonke izilungiselelo ngaphandle kwe-Application (o61) kanye nekheli (o03) zizokopishwa. Uma ukukopisha sekuqalile isibonisi sibuyela ku-o65. Ngemuva kwemizuzwana emibili ungangena futhi kumenyu futhi uhlole ukuthi ukukopisha kuyagculisa yini. Ukubonisa isibalo esingalungile kusho izinkinga. Bona ukubaluleka esigabeni esithi Fault Message. |

o65 | – |

| Kopisha kusuka kukhiye wokuhlela

Lo msebenzi ulanda isethi yezilungiselelo ezigcinwe ngaphambilini kusilawuli. Khetha inombolo efanele. Zonke izilungiselelo ngaphandle kwe-Application (o61) kanye nekheli (o03) zizokopishwa. Uma ukukopisha sekuqalile isibonisi sibuyela ku-o66. Ngemva kwemizuzwana emibili ungakwazi ukubuyela emuva kumenyu futhi uhlole ukuthi ukukopisha kuyagculisa yini. Ukubonisa isibalo esingalungile kusho izinkinga. Bona ukubaluleka kusigaba somlayezo onephutha. |

o66 | – |

| Londoloza njengesilungiselelo sasefekthri

Ngalesi silungiselelo ulondoloza izilungiselelo zangempela zesilawuli njengesilungiselelo esisha esiyisisekelo (izilungiselelo zangaphambilini zasembonini zibhalwa ngaphezulu). |

o67 | – |

| – – – Ukubuyisela emuva Ebusuku 0=Usuku

1=Ubusuku |

| Isevisi | Isevisi | |

| Izinga lokushisa likalwe ngenzwa ye-S5 | u09 | Izinga lokushisa le-S5. |

| Isimo kokokufaka kwe-DI1. ku/1=kuvaliwe | u10 | Isimo se-DI1 |

| Izinga lokushisa likalwe ngenzwa ye-S3 | u12 | Izinga lokushisa lomoya le-S3 |

| Isimo sokusebenza ebusuku (kuvuliwe noma kuvaliwe) 1=kuvaliwe | u13 | I-Night Cond. |

| Izinga lokushisa likalwe ngenzwa ye-S4 | u16 | Izinga lokushisa lomoya le-S4 |

| Izinga lokushisa le-thermostat | u17 | Ther. umoya |

| Funda inkomba yamanje yomthetho | u28 | Temp. ref. |

| Isimo ekuphumeni kwe-DI2. ku/1=kuvaliwe | u37 | Isimo se-DI2 |

| Izinga lokushisa liboniswa ekubonisweni | u56 | Bonisa umoya |

| Izinga lokushisa elilinganiselwe le-alamu thermostat | u57 | Umoya we-alamu |

| ** Isimo ku-relay yokupholisa | u58 | I-Comp1/LLSV |

| ** Isimo sokudluliswa kwabalandeli | u59 | Ukudluliselwa kwabalandeli |

| ** Isimo edluliselwe for defrost | u60 | Def. udlulise |

| ** Isimo ku-relay ye-railheat | u61 | Railh. udlulise |

| ** Isimo ekudlulisweni kwe-alamu | u62 | I-alamu edluliselwe |

| ** Isimo sokudluliswa kokukhanya | u63 | Ukudlulisa ukukhanya |

| ** Isimo sokudluliswa kwe-valve kumugqa wokumunca | u64 | I-SuctionValve |

| ** Isimo sokudluliswa kwe-compressor 2 | u67 | I-Comp2 edluliselwe |

| *) Akuzona zonke izinto ezizoboniswa. Umsebenzi wohlelo olukhethiwe kuphela ongabonwa. |

| Umlayezo wephutha | Ama-alamu | |

| Uma kunephutha ama-LED angaphambili azokhanyisa bese kuthi i-alamu isebenze. Uma ucindezela inkinobho ephezulu kulesi simo ungabona umbiko we-alamu kusibonisi. Uma kukhona abaningi qhubeka nokuphusha ukuze ubabone.

Kunezinhlobo ezimbili zemibiko yephutha - kungaba i-alamu eyenzeka phakathi nokusebenza kwansuku zonke, noma kungase kube khona iphutha ekufakeni. Ama-alamu ngeke abonakale kuze kube yilapho ukubambezeleka kwesikhathi esimisiwe kuphelelwe yisikhathi. Ama-alamu e-E, ngakolunye uhlangothi, azobonakala lapho iphutha lenzeka. (I-alamu ngeke ibonakale inqobo nje uma kukhona i-alamu ka-E esebenzayo). Nansi imilayezo engavela: |

1 = i-alamu |

|

| I-A1: I-alamu yokushisa okuphezulu | Phezulu t. i-alamu | |

| A2: I-alamu yokushisa ephansi | Okuphansi t. i-alamu | |

| A4: I-alamu yomnyango | I-Alarm Yomnyango | |

| A5: Ulwazi. Ipharamitha engu-o16 iphelelwe yisikhathi | I-Max Hold Time | |

| A15: I-alamu. Isiginali evela ku-DI1 okokufaka | I-alamu ye-DI1 | |

| A16: I-alamu. Isiginali evela ku-DI2 okokufaka | I-alamu ye-DI2 | |

| I-A45: Indawo elindile (isiqandisi esimisiwe nge-r12 noma i-DI input) (I-alamu edluliswayo ngeke yenziwe isebenze) | Imodi yokulinda | |

| A59: Ukuhlanzwa kwecala. Isiginali evela ku-DI1 noma okokufaka kwe-DI2 | Ukuhlanzwa kwecala | |

| I-A60: I-alamu yokushisa ephezulu yomsebenzi we-HACCP | I-alamu ye-HACCP | |

| Ubukhulu. def isikhathi | ||

| E1: Amaphutha kusilawuli | Iphutha le-EKC | |

| I-E6: Iphutha ewashini lesikhathi sangempela. Hlola ibhethri / setha kabusha iwashi. | – | |

| I-E25: Iphutha lenzwa ku-S3 | Iphutha le-S3 | |

| I-E26: Iphutha lenzwa ku-S4 | Iphutha le-S4 | |

| I-E27: Iphutha lenzwa ku-S5 | Iphutha le-S5 | |

Lapho ukopisha izilungiselelo ukuya noma ukusuka kukhiye wokukopisha onemisebenzi ethi O65 noma o66, ulwazi olulandelayo lungase luvele:

(Ulwazi lungatholakala ku-o65 noma ku-o66 imizuzwana embalwa ngemva kokuthi kuqalisiwe ukukopisha). |

||

| Izindawo ze-alamu | ||

| Ukubaluleka kwama-alamu angawodwana kungachazwa ngesilungiselelo (0, 1, 2 noma 3) |

| Isimo sokusebenza | (Isikali) | |

| Isilawuli sidlula ezimeni ezithile zokulawula lapho sivele silinde iphuzu elilandelayo lomthethonqubo. Ukwenza lezi zimo "kungani kungenzeki" izimo

ebonakalayo, ungabona isimo sokusebenza esibukweni. Cindezela kafushane (1s) inkinobho engenhla. Uma kunekhodi yesimo, izovezwa esibukweni. Amakhodi esimo angawodwana anezincazelo ezilandelayo: |

Isifunda se-EKC:

(Kuboniswa kuzo zonke izibonisi zemenyu) |

|

| S0: Ukulawula | 0 | |

| I-S1: Ilinde ukuphela kokumiswa kweqhwa okuhlanganisiwe | 1 | |

| I-S2: Uma i-compressor isebenza kufanele isebenze okungenani imizuzu engu-x. | 2 | |

| S3: Uma i-compressor imiswa, kufanele ihlale imile okungenani imizuzu engu-x. | 3 | |

| I-S4: I-evaporator iyaconsa bese ilinda ukuthi isikhathi siphele | 4 | |

| I-S10: Isiqandisi simiswa ngokushintsha okukhulu. Nge-r12 noma i-DI-input | 10 | |

| I-S11: Isiqandisi simiswe yi-thermostat | 11 | |

| I-S14: Ukulandelana kwe-Defrost. Ukumiswa kweqhwa kuyaqhubeka | 14 | |

| I-S15: Ukulandelana kwe-Defrost. Ukubambezeleka kwabalandeli - amanzi anamathela ku-evaporator | 15 | |

| S17: Umnyango uvuliwe. Okokufaka kwe-DI kuvuliwe | 17 | |

| S20: Ukupholisa okuphuthumayo *) | 20 | |

| I-S25: Ukulawula okwenziwa ngesandla ngesandla | 25 | |

| S29: Ukuhlanzwa kwecala | 29 | |

| I-S30: Ukupholisa ngempoqo | 30 | |

| S32: Ukubambezeleka kokuphumayo ngesikhathi sokuqalisa | 32 | |

| I-S33: Umsebenzi wokushisa u-r36 uyasebenza | 33 | |

| Eminye imibukiso: | ||

| okungezona: Izinga lokushisa le-defrost alikwazi ukuboniswa. Kukhona ukuma okusekelwe esikhathini | ||

| -d-: I-Defrost iyaqhubeka / Ukupholisa kokuqala ngemva kokumiswa kweqhwa | ||

| PS: Kudingeka iphasiwedi. Setha iphasiwedi |

*) Ukupholisa isimo esiphuthumayo kuzosebenza uma kuntuleka isignali evela kunzwa ye-S3 noma i-S4 echaziwe. Umthethonqubo uzoqhubeka ne-avareji ye-cutin frequency ebhalisiwe. Kunamanani amabili abhalisiwe - elilodwa elokusebenza emini nelilodwa elokusebenza ebusuku.

Isexwayiso ! Ukuqala okuqondile kwama-compressor *

Ukuze uvimbele ipharamitha yokuphuka kwe-compressor c01 kanye ne-c02 kufanele isethwe ngokuvumelana nezimfuneko zabahlinzeki noma ngokujwayelekile : I-Hermetic Compressors c02 min. 5 amaminithi

I-Semihermetic Compressors c02 min. 8 amaminithi c01 min. Imizuzu emi-2 ukuya kwemi-5 (Injini isuka ku-5 ukuya ku-15 KW)

* ) Ukusebenza okuqondile kwama-valve e-solenoid akudingi izilungiselelo ezihlukile kufekthri (0)

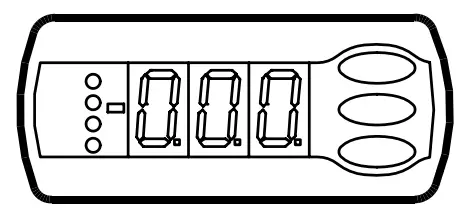

Ukusebenza

Bonisa

Amanani azoboniswa ngamadijithi amathathu, futhi ngesilungiselelo ungakwazi ukunquma ukuthi izinga lokushisa kufanele liboniswe ngo-°C noma ngo-°F.

Ama-diode akhipha ukukhanya (i-LED) kuphaneli yangaphambili

I-HACCP = Umsebenzi we-HACCP uyasebenza

Amanye ama-LED akuphaneli yangaphambili azokhanya uma i-relay engumnikazi wayo icushiwe.

Ama-diode akhipha ukukhanya azokhanya uma kune-alamu.

Kulesi simo ungadawuniloda ikhodi yephutha kusibonisi futhi ukhansele/usayinele i-alamu ngokunikeza ifindo eliphezulu ukusunduza kafushane.

I-Defrost

Ngesikhathi sokunciphisa u-a –d- uyakhonjiswa esibukweni. Lokhu view izoqhubeka kuze kube yimizuzu eyi-15. ngemva kokuba ukupholisa sekuqale kabusha.

Nokho i view of -d- izoyekiswa uma:

- Izinga lokushisa lifanelekile phakathi nemizuzu engu-15

- Umthetho umiswa ngokuthi “Main Switch”

- Kuvela i-alamu yezinga lokushisa eliphezulu

Izinkinobho

Uma ufuna ukushintsha isilungiselelo, izinkinobho ezingenhla nezingezansi zizokunikeza inani eliphezulu noma eliphansi kuye ngenkinobho oyicindezelayo. Kodwa ngaphambi kokuthi ushintshe inani, kufanele ube nokufinyelela kumenyu. Lokhu ukuthola ngokucindezela inkinobho engenhla imizuzwana embalwa - uzofaka ikholamu enamakhodi epharamitha. Thola ikhodi yepharamitha ofuna ukuyishintsha bese ucindezela izinkinobho ezimaphakathi kuze kube yilapho kuboniswa inani lepharamitha. Uma usushintshile inani, londoloza inani elisha ngokucindezela futhi inkinobho ephakathi nendawo.

ExampLes

Setha imenyu

- Cindezela inkinobho engenhla kuze kuvele ipharamitha ethi r01

- Cindezela inkinobho engenhla noma engezansi bese uthola leyo pharamitha ofuna ukuyishintsha

- Cindezela inkinobho ephakathi kuze kuvele inani lepharamitha

- Cindezela inkinobho engenhla noma engezansi bese ukhetha inani elisha

- Cindezela inkinobho ephakathi futhi ukuze umise inani.

I-alamu yokusika edluliselwe / i-alamu yerisidi/bona ikhodi ye-alamu

- Cindezela inkinobho engenhla ibe mfushane

Uma kukhona amakhodi ama-alamu amaningana atholakala ku-rolling stack. Cindezela inkinobho ephezulu kakhulu noma ephansi ukuze uskene isitaki esigoqayo.

Setha izinga lokushisa

- Cindezela inkinobho ephakathi kuze kubonakale inani lokushisa

- Cindezela inkinobho engenhla noma engezansi bese ukhetha inani elisha

- Cindezela inkinobho ephakathi futhi ukuze uphethe isilungiselelo.

Ukufunda izinga lokushisa ngenzwa ye-defrost

Cindezela inkinobho engezansi

U-Manuel uqala noma ayeke ukuncibilika

Cindezela inkinobho engezansi imizuzwana emine.(Nakuba kungenjalo okohlelo lokusebenza 4).

Bheka ukubhaliswa kwe-HACCP

- Nika inkinobho ephakathi ukuphusha isikhathi eside kuze kuvele u-h01

- Khetha okudingekayo h01-h10

- Bona inani ngokunikeza inkinobho emaphakathi ukucindezela okufushane

Qala kahle

Ngenqubo elandelayo ungaqala ukulawula ngokushesha okukhulu:

- Vula ipharamitha engu-r12 bese umisa isimiso (eyunithi entsha nengasethiwe ngaphambili, u-r12 uzobe esebekwe ku-0 okusho ukuthi umthetho omisiwe.)

- Khetha ukuxhumana kukagesi okusekelwe emidwebeni esekhasini lesi-6

- Vula ipharamitha u-o61 bese usetha inombolo yokuxhuma ugesi kuyo

- Manje khetha enye yezilungiselelo ezisethiwe etafuleni ekhasini 22.

- Vula ipharamitha u-o62 bese usetha inombolo yohlu lokusethwa ngaphambilini. Izilungiselelo ezimbalwa ezikhethiwe manje zizodluliselwa kumenyu.

- Vula ipharamitha r12 bese uqala umthethonqubo

- Dlula kunhlolovo yezilungiselelo zefekthri. Amanani kumaseli ampunga ashintshwa ngokuya ngezilungiselelo ozikhethayo. Yenza noma yiziphi izinguquko ezidingekayo kumapharamitha afanele.

- Okwenethiwekhi. Setha ikheli kokuthi o03 bese ulidlulisela esangweni/kuyunithi yesistimu enokusetha okuthi o04.

I-HACCP

Lo msebenzi uzolandela izinga lokushisa likagesi futhi ukhale i-alamu uma umkhawulo wokushisa omisiwe weqiwe. I-alamu izofika uma ukubambezeleka kwesikhathi sekudlulile.

Uma izinga lokushisa lidlula inani elilinganiselwe lizobhaliswa ngokuqhubekayo futhi inani eliphakeme lizogcinwa kuze kube yilapho kuphinda kuphindwe kamuva. Kulondolozwe kanye nenani kuzoba isikhathi nobude bezinga lokushisa elidlulayo.

Exampizinga lokushisa elingaphansi:

Ukweqa ngesikhathi sokulawulwa okuvamile

Ukweqa mayelana nokuhluleka kwamandla lapho isilawuli singakwazi ukuqhubeka nokubhalisa ukusebenza kwesikhathi.

Ukweqa mayelana nokuhluleka kwamandla lapho isilawuli silahlekelwe umsebenzi waso wewashi futhi ngenxa yalokho nokusebenza kwaso kwesikhathi.

Ukufundwa kwamanani ahlukahlukene kumsebenzi we-HACCP kungenzeka ngokucindezela isikhathi eside inkinobho ephakathi.

Izifundo zimi kanje:

- h01: Izinga lokushisa

- h02: Ukufundwa kwesimo sesilawuli lapho izinga lokushisa leqiwa:

- H1 = umthethonqubo ojwayelekile.

- H2 = ukuhluleka kwamandla. Izikhathi zilondoloziwe.

- H3 = ukuhluleka kwamandla. Izikhathi azilondoloziwe.

- h03: isikhathi. Unyaka

- h04: isikhathi. Inyanga

- h05: Isikhathi: Usuku

- h06: isikhathi. Ihora

- h07: isikhathi. Iminithi

- h08: Ubude besikhathi ngamahora

- h09: Ubude besikhathi ngamaminithi

- h10: Izinga lokushisa eliphakeme elibhalisiwe

(Ukusethwa komsebenzi kwenzeka njengezinye izinhlelo. Bheka inhlolovo yemenyu ekhasini elilandelayo).

| Amapharamitha | Inombolo yomdwebo we-EL (ikhasi 6) | Min.-

inani |

Ubuningi.-

inani |

Ifekthri

setting |

Okwangempela

setting |

|||||||||||

| Umsebenzi | Amakhodi | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |||||

| Ukusebenza okuvamile | ||||||||||||||||

| Izinga lokushisa (set point) | — | -50.0°C | 50.0°C | 2.0°C | ||||||||||||

| I-Thermostat | ||||||||||||||||

| Umehluko | *** | r01 | 0.1 K | 20.0K | 2.0 K | |||||||||||

| Ubukhulu. umkhawulo wokusetha iphuzu | *** | r02 | -49.0°C | 50°C | 50.0°C | |||||||||||

| Okuncane. umkhawulo wokusetha iphuzu | *** | r03 | -50.0°C | 49.0°C | -50.0°C | |||||||||||

| Ukulungiswa kwenkomba yokushisa | r04 | -20.0 k | 20.0 K | 0.0 K | ||||||||||||

| Iyunithi yezinga lokushisa (°C/°F) | r05 | °C | °F | °C | ||||||||||||

| Ukulungiswa kwesiginali kusuka ku-S4 | r09 | -10.0 k | +10.0 K | 0.0 K | ||||||||||||

| Ukulungiswa kwesiginali kusuka ku-S3 | r10 | -10.0 k | +10.0 K | 0.0 K | ||||||||||||

| Isevisi yezandla, ukumisa isimiso, ukuqala isimiso (-1, 0, 1) | r12 | -1 | 1 | 0 | ||||||||||||

| Ukususwa kwereferensi ngesikhathi sokusebenza ebusuku | r13 | -10.0 k | 10.0 K | 0.0 K | ||||||||||||

| Incazelo kanye nesisindo, uma sikhona, sezinzwa ze-thermostat

– S4% (100%=S4, 0%=S3) |

r15 | 0% | 100% | 100% | ||||||||||||

| Umsebenzi wokushisisa uqalwa ngamadigri ambalwa ngaphansi kwe

izinga lokushisa lokusika le-thermostats |

r36 | -15.0 k | -3.0 k | -15.0 k | ||||||||||||

| Ukwenza kusebenze i-reference displacement r40 | r39 | VALIWE | ON | VALIWE | ||||||||||||

| Inani lereferensi yokususwa (yenza isebenze nge-r39 noma i-DI) | r40 | -50.0 k | 50.0 K | 0.0 K | ||||||||||||

| I-alamu | ||||||||||||||||

| Ukubambezeleka kwe-alamu yezinga lokushisa | A03 | 0 imiz | 240 imiz | 30 imiz | ||||||||||||

| Ukubambezeleka kwe-alamu yomnyango | *** | A04 | 0 imiz | 240 imiz | 60 imiz | |||||||||||

| Ukubambezeleka kwe-alamu yezinga lokushisa ngemva kokumiswa kweqhwa | A12 | 0 imiz | 240 imiz | 90 imiz | ||||||||||||

| Umkhawulo we-alamu ophezulu | *** | A13 | -50.0°C | 50.0°C | 8.0°C | |||||||||||

| Umkhawulo we-alamu ophansi | *** | A14 | -50.0°C | 50.0°C | -30.0°C | |||||||||||

| Ukubambezeleka kwe-alamu DI1 | A27 | 0 imiz | 240 imiz | 30 imiz | ||||||||||||

| Ukubambezeleka kwe-alamu DI2 | A28 | 0 imiz | 240 imiz | 30 imiz | ||||||||||||

| Isiginali ye-alamu thermostat. I-S4% (100%=S4, 0%=S3) | A36 | 0% | 100% | 100% | ||||||||||||

| I-Compressor | ||||||||||||||||

| Okuncane. Ngesikhathi | c01 | 0 imiz | 30 imiz | 0 imiz | ||||||||||||

| Okuncane. ISIKHATHI esingasebenzi | c02 | 0 imiz | 30 imiz | 0 imiz | ||||||||||||

| Ukubambezeleka kwesikhathi se-cutin of comp.2 | c05 | 0 isekhondi | 999 isekhondi | 0 isekhondi | ||||||||||||

| I-Compressor relay 1 kumele inqunywe futhi iphume ngokuphambene

(NC-umsebenzi) |

c30 | 0

VALIWE |

1

ON |

0

VALIWE |

||||||||||||

| I-Defrost | ||||||||||||||||

| Indlela yokuncibilika (ayikho/EL/GAS/BRINE) | d01 | cha | bri | EL | ||||||||||||

| Defrost stop lokushisa | d02 | 0.0°C | 25.0°C | 6.0°C | ||||||||||||

| Isikhawu phakathi kokuqala kwe-defrost | d03 | 0 amahora | 240

amahora |

8 amahora | ||||||||||||

| Ubukhulu. ubude be-defrost | d04 | 0 imiz | 180 imiz | 45 imiz | ||||||||||||

| Ukushintshwa kwesikhathi ku-cutin of defrost ekuqaleni | d05 | 0 imiz | 240 imiz | 0 imiz | ||||||||||||

| Isikhathi sokuphumula | d06 | 0 imiz | 60 imiz | 0 imiz | ||||||||||||

| Ukubambezeleka kokuqala kwefeni ngemva kokumiswa kwesithwathwa | d07 | 0 imiz | 60 imiz | 0 imiz | ||||||||||||

| Izinga lokushisa lokuqala labalandeli | d08 | -15.0°C | 0.0°C | -5.0°C | ||||||||||||

| I-Fan cutin ngesikhathi sokushisa

0: Kumisiwe 1: Ukugijima 2: Ukugijima ngesikhathi sokupompa phansi kanye nokuncibilika |

d09 | 0 | 2 | 1 | ||||||||||||

| Inzwa ye-Defrost (0=isikhathi, 1=S5, 2=S4) | d10 | 0 | 2 | 0 | ||||||||||||

| Pump phansi ukubambezeleka | d16 | 0 imiz | 60 imiz | 0 imiz | ||||||||||||

| Ukulibaziseka kokukhipha amanzi | d17 | 0 imiz | 60 imiz | 0 imiz | ||||||||||||

| Ubukhulu. isikhathi sesiqandisi esihlanganisiwe phakathi kwama-defrosts amabili | d18 | 0 amahora | 48 amahora | 0 amahora | ||||||||||||

| I-Defrost uma idingeka - ukuhluka okuvunyelwe kwezinga lokushisa le-S5 phakathi no-

ukwakha isithwathwa. Embonini emaphakathi khetha 20 K (=off) |

d19 | 0.0 K | 20.0 k | 20.0 K | ||||||||||||

| Ukubambezeleka kwe-hot defrost | d23 | 0 imiz | 60 imiz | 0 imiz | ||||||||||||

| Umlandeli | ||||||||||||||||

| Yima abalandeli ku-cutout compressor | F01 | cha | yebo | cha | ||||||||||||

| Ukubambezeleka kokuma kwabalandeli | F02 | 0 imiz | 30 imiz | 0 imiz | ||||||||||||

| Izinga lokushisa lokumisa abalandeli (S5) | F04 | -50.0°C | 50.0°C | 50.0°C | ||||||||||||

| I-HACCP | ||||||||||||||||

| Isilinganiso sokushisa sangempela somsebenzi we-HACCP | h01 | |||||||||||||||

| Izinga lokushisa eliphakeme elibhalisiwe lokugcina | h10 | |||||||||||||||

| Ukukhethwa komsebenzi kanye nenzwa yomsebenzi we-HACCP. 0 = no

Umsebenzi we-HACCP. 1 = S4 esetshenzisiwe (mhlawumbe futhi S3). 2 = S5 esetshenzisiwe |

h11 | 0 | 2 | 0 | ||||||||||||

| Umkhawulo we-alamu womsebenzi we-HACCP | h12 | -50.0°C | 50.0°C | 8.0°C | ||||||||||||

| Ukubambezeleka kwesikhathi kwe-alamu ye-HACCP | h13 | 0 imiz. | 240 imiz. | 30 imiz. | ||||||||||||

| Khetha isiginali yomsebenzi we-HACCP. I-S4% (100% = S4, 0% = S3) | h14 | 0% | 100% | 100% | ||||||||||||

| Isikhathi sangempela sewashi | ||||||||||||||||

| Izikhathi eziyisithupha zokuqala zokuncibilika. Ukusetha amahora.

0 = VALIWE |

t01-t06 | 0 amahora | 23 amahora | 0 amahora | ||||||||||||

| Izikhathi eziyisithupha zokuqala zokuncibilika. Ukusethwa kwamaminithi.

0 = VALIWE |

t11-t16 | 0 imiz | 59 imiz | 0 imiz | ||||||||||||

| Iwashi - Ukusetha amahora | *** | t07 | 0 amahora | 23 amahora | 0 amahora | |||||||||||

| Iwashi - Ukusetha umzuzu | *** | t08 | 0 imiz | 59 imiz | 0 imiz | |||||||||||

| Iwashi – Ukusetha usuku | *** | t45 | 1 | 31 | 1 | |||||||||||

| Iwashi – Ukulungiselelwa kwenyanga | *** | t46 | 1 | 12 | 1 | |||||||||||

| Iwashi - Ukuhlelwa konyaka | *** | t47 | 0 | 99 | 0 | |||||||||||

| Okunhlobonhlobo | ||||||||||||||||

| Ukubambezeleka kwamasignali okukhiphayo ngemva kokuhluleka kwamandla | o01 | 0 s | 600 s | 5 s | ||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |||||||

| Isiginali yokokufaka ku-DI1. Umsebenzi:

0=ayisetshenziswanga. 1=isimo ku-DI1. 2=umsebenzi womnyango one-alamu uma uvuliwe. 3=i-alamu yomnyango uma ivuliwe. 4=ukuqala kokuncibilika (i-pulse-signal). 5=ext.iswishi enkulu. 6=ukusebenza ebusuku 7=shintsha ireferensi (vula u-r40). 8=i-alamu uma ivaliwe. 9=i-alamu uma ivuliwe. 10=ukuhlanzwa kwekesi (i-pulse signal). 11=ukupholisa ngempoqo ekuncibilikisweni kwegesi eshisayo. |

o02 | 1 | 11 | 0 | ||||||||||||

| Ikheli lenethiwekhi | o03 | 0 | 240 | 0 | ||||||||||||

| Iswishi yokuvula/ukuvala (umlayezo wephinikhodi yesevisi)

KUBALULEKILE! o61 kufanele ibekwe ngaphambi kwe-o04 |

o04 | VALIWE | ON | VALIWE | ||||||||||||

| Ikhodi yokufinyelela 1 (zonke izilungiselelo) | o05 | 0 | 100 | 0 | ||||||||||||

| Uhlobo lwenzwa esetshenzisiwe (Pt/PTC/NTC) | o06 | Pt | ntc | Pt | ||||||||||||

| Isinyathelo sokubonisa = 0.5 (okujwayelekile okungu-0.1 kunzwa ye-Pt) | o15 | cha | yebo | cha | ||||||||||||

| Isikhathi esiphezulu sokubamba ngemva kokumiswa kweqhwa okuhlanganisiwe | o16 | 0 imiz | 60 imiz | 20 | ||||||||||||

| Khetha isignali ukuze ubonise view. I-S4% (100%=S4, 0%=S3) | o17 | 0% | 100% | 100% | ||||||||||||

| Isiginali yokokufaka ku-DI2. Umsebenzi:

(0=akusetshenziswanga. 1=isimo ku-DI2. 2=umsebenzi womnyango one-alamu uma uvuliwe. 3=i-alamu yomnyango uma ivuliwe. 4=ukuqala kokuncibilika kweqhwa (i-pulse-signal). 5=ext. main switch 6=ukusebenza kwasebusuku 7=shintsha ireferensi (yenza kusebenze u-r40). 8=i-alamu uma ivaliwe. 9=i-alamu lapho ivuliwe.10=i-alamu yokuhlanza lapho ivuliwe. 11=isignali ye-alamu lapho ivuliwe). i-gas defrost.). 12=i-coordinated defrost) |

o37 | 0 | 12 | 0 | ||||||||||||

| Ukucushwa komsebenzi wokukhanya (i-relay 4)

1=VULIWE phakathi nokusebenza kosuku. 2=VULIWE / VALIWE ngokuxhumana kwedatha. 3=ON ilandela i-DI-function, lapho i-DI ikhethelwa umsebenzi womnyango noma i-alamu yomnyango |

o38 | 1 | 3 | 1 | ||||||||||||

| Ukwenza kusebenze i-relay yokukhanya (kuphela uma o38=2) | o39 | VALIWE | ON | VALIWE | ||||||||||||

| Ukushisa kukaloliwe Ngesikhathi ngesikhathi sokusebenza kosuku | o41 | 0% | 100% | 100 | ||||||||||||

| Ukushisa kukaloliwe Ngesikhathi ngesikhathi sokusebenza ebusuku | o42 | 0% | 100% | 100 | ||||||||||||

| Isikhathi sokushisa kukaloliwe (Isikhathi + nesikhathi sokungasebenzi) | o43 | 6 imiz | 60 imiz | 10 imiz | ||||||||||||

| Ukuhlanzwa kwecala. 0=akukho ukuhlanzwa kwekesi. 1=Abalandeli kuphela. 2=Konke okukhiphayo

Valiwe. |

*** | o46 | 0 | 2 | 0 | |||||||||||

| Ukukhethwa komdwebo we-EL. Bona ngaphaview ikhasi 6 | * | o61 | 1 | 10 | 1 | |||||||||||

| Landa isethi yezilungiselelo ezinqunywe kusengaphambili. Bona ngaphaview Olandelayo

ikhasi. |

* | o62 | 0 | 6 | 0 | |||||||||||

| Ikhodi yokufinyelela 2 (ukufinyelela ngokwengxenye) | *** | o64 | 0 | 100 | 0 | |||||||||||

| Londoloza izilungiselelo zamanje zezilawuli kukhiye wokuhlela.

Khetha inombolo yakho. |

o65 | 0 | 25 | 0 | ||||||||||||

| Layisha isethi yezilungiselelo kusuka kukhiye wokuhlela (ngaphambilini

ilondolozwe ngomsebenzi we-o65) |

o66 | 0 | 25 | 0 | ||||||||||||

| Miselela izilungiselelo zasembonini zezilawuli ngesethi yamanje-

tings |

o67 | VALIWE | On | VALIWE | ||||||||||||

| Isevisi | ||||||||||||||||

| Amakhodi esimo aboniswa ekhasini lesi-17 | I-S0-S33 | |||||||||||||||

| Izinga lokushisa likalwe ngenzwa ye-S5 | *** | u09 | ||||||||||||||

| Isimo kokokufaka kwe-DI1. ku/1=kuvaliwe | u10 | |||||||||||||||

| Izinga lokushisa likalwe ngenzwa ye-S3 | *** | u12 | ||||||||||||||

| Isimo sokusebenza ebusuku (kuvuliwe noma kuvaliwe) 1=kuvaliwe | *** | u13 | ||||||||||||||

| Izinga lokushisa likalwe ngenzwa ye-S4 | *** | u16 | ||||||||||||||

| Izinga lokushisa le-thermostat | u17 | |||||||||||||||

| Funda inkomba yamanje yomthetho | u28 | |||||||||||||||

| Isimo ekuphumeni kwe-DI2. ku/1=kuvaliwe | u37 | |||||||||||||||

| Izinga lokushisa liboniswa ekubonisweni | u56 | |||||||||||||||

| Izinga lokushisa elilinganiselwe le-alamu thermostat | u57 | |||||||||||||||

| Isimo ku-relay yokupholisa | ** | u58 | ||||||||||||||

| Isimo ekudlulisweni kwefeni | ** | u59 | ||||||||||||||

| Isimo ekudlulisweni kwe-defrost | ** | u60 | ||||||||||||||

| Isimo ku-relay ye-railheat | ** | u61 | ||||||||||||||

| Isimo ekudlulisweni kwe-alamu | ** | u62 | ||||||||||||||

| Isimo ekudlulisweni kokukhanya | ** | u63 | ||||||||||||||

| Isimo ku-relay ye-valve kumugqa wokumunca | ** | u64 | ||||||||||||||

| Isimo ekudlulisweni kwe-compressor 2 | ** | u67 | ||||||||||||||

*) Ingasethwa kuphela uma umthetho umisiwe (r12=0)

**) Ingalawulwa ngesandla, kodwa kuphela uma r12=-1

***) Ngekhodi yokungena 2 ukufinyelela kulawa mamenyu kuzonqunyelwa

Isilungiselelo sasefekthri

Uma udinga ukubuyela kumanani asethwe njengasekuqaleni, kungenziwa ngale ndlela:

- Sika umthamo wokunikezelatage kusilawuli

- Gcina zombili izinkinobho zicindezelekile ngesikhathi esifanayo njengoba uphinda uhlanganisa umthamo wokunikezelatage

| Ithebula elisizayo lezilungiselelo (ukusetha ngokushesha) | Icala | Igumbi | ||||

| I-Defrost stop ngesikhathi | I-Defrost stop ku-S5 | I-Defrost stop ngesikhathi | I-Defrost stop ku-S5 | |||

| Setha ngaphambilini izilungiselelo (o62) | 1 | 2 | 3 | 4 | 5 | 6 |

| Izinga lokushisa (SP) | 4°C | 2°C | -24°C | 6°C | 3°C | -22°C |

| Ubukhulu. isikhashana. isilungiselelo (r02) | 6°C | 4°C | -22°C | 8°C | 5°C | -20°C |

| Okuncane. isikhashana. isilungiselelo (r03) | 2°C | 0°C | -26°C | 4°C | 1°C | -24°C |

| Isignali yenzwa ye-thermostat. I-S4% (r15) | 100% | 0% | ||||

| Umkhawulo we-alamu uphezulu (A13) | 10°C | 8°C | -15°C | 10°C | 8°C | -15°C |

| Umkhawulo we-alamu uphansi (A14) | -5°C | -5°C | -30°C | 0°C | 0°C | -30°C |

| Isignali yenzwa yomsebenzi we-alamu.S4% (A36) | 100% | 0% | ||||

| Isikhawu phakathi kwe-defrost (d03) | 6 h | 6h | 12h | 8h | 8h | 12h |

| Inzwa ye-Defrost: 0=isikhathi, 1=S5, 2=S4 (d10) | 0 | 1 | 1 | 0 | 1 | 1 |

| I-DI1 config. (o02) | Ukuhlanzwa kwekesi (=10) | Umsebenzi womnyango (=3) | ||||

| Isignali yenzwa yokuboniswa view I-S4% (017) | 100% | 0% | ||||

Khipha

Isilawuli siqukethe inani lemisebenzi engasetshenziswa ukuze-ndawonye nomsebenzi wokukhipha ku-master gateway / Isiphathi Sesistimu.

|

Umsebenzi ngokuxhumana kwedatha |

Imisebenzi ezosetshenziswa emasangweni khipha umsebenzi |

Ipharamitha esetshenziswa ku-AK-CC 210 |

| Ukuqala kwe-defrosting | Isikhathi sokulawula i-Defrost | – – – Def.start |

|

I-defrost ehlanganisiwe |

Ukulawula i-Defrost |

– – – HoldAfterDef u60 Def.relay |

|

Ukubuyela emuva ebusuku |

Ukulawula usuku/ubusuku Isheduli yesikhathi |

– – – Ukusetha ebusuku |

| Ukulawula ukukhanya | Ukulawula usuku/ubusuku Isheduli yesikhathi | o39 Isilawuli kude esikhanyayo |

Iya-oda

Ukuxhumana

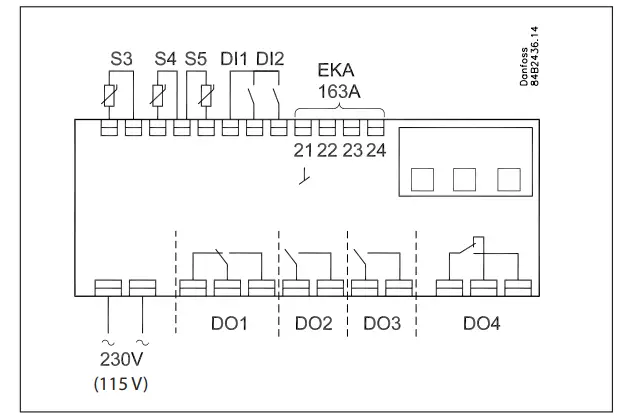

Ukunikezwa kwamandla kagesi

230 V ac

Izinzwa

I-S3 ne-S4 izinzwa ze-thermostat.

Isilungiselelo sinquma ukuthi i-S3 noma i-S4 noma zombili zizosetshenziswa yini.

I-S5 iyinzwa ye-defrost futhi isetshenziswa uma i-defrost kufanele imiswe ngokuya ngezinga lokushisa.

Izimpawu zeDijithali Zivuliwe/Zivaliwe

Okokufaka okusikiwe kuzovula umsebenzi. Imisebenzi engenzeka ichazwe kumamenyu o02 kanye no-o37.

Isibonisi sangaphandle

Ukuxhumeka kohlobo lokubonisa i-EKA 163A (EKA 164A).

Ukudluliselwa

Ukusetshenziswa okuvamile kubalulwe lapha. Bheka futhi ikhasi 6 lapho kukhonjiswa khona izinhlelo zokusebenza ezahlukene.

- I-DO1: Isiqandisi. I-relay izongena lapho isilawuli sifuna isiqandisi

- I-DO2: I-Defrost. I-relay izongena lapho ukucwiliswa kweqhwa kuqhubeka

- DO3: Kungaba abalandeli noma isiqandisi 2

Abalandeli: I-relay izongena lapho abalandeli sekufanele basebenzise Isiqandisi 2: I-relay izonqamula uma isiqandisi sesi-2 kufanele sinqanyulwe. - I-DO4: Nge-alamu, ukushisa kukaloliwe, ukukhanya noma i-hotgas defrost I-alamu: Cf. umdwebo. I-relay inqanyulwa phakathi ngesikhathi sokusebenza okuvamile futhi iyanqamuka ezimeni ze-alamu nalapho isilawuli sifile (siphelelwa amandla)

Ukushisa kukaloliwe: I-relay iyanqamuka lapho ukushisa kukaloliwe kuzosebenza

Ukukhanya: I-relay iyanqamula lapho ukukhanya kufanele kuvulwe i-Hotgas defrost: Bona umdwebo. I-relay izonqamuka lapho i-defrost kufanele yenziwe

Ukuxhumana kwedatha

Isilawuli sitholakala ezinguqulweni ezimbalwa lapho ukuxhumana kwedatha kungenziwa ngenye yalezi zinhlelo ezilandelayo: MOD-bus noma LON-RS485.

Uma ukuxhumana kwedatha kusetshenziswa, kubalulekile ukuthi ukufakwa kwekhebula lokuxhumana kwedatha kwenziwe ngendlela efanele.

Bona izincwadi ezihlukene No. RC8AC...

Umsindo kagesi

Amakhebuli wezinzwa, okokufaka kwe-DI kanye nokuxhumana kwedatha kufanele kugcinwe kuhlukene kwezinye izintambo zikagesi:

- Sebenzisa amathreyi ekhebula ahlukene

- Gcina ibanga phakathi kwezintambo okungenani libe ngu-10 cm

- Izintambo ezinde kokokufaka kwe-DI kufanele zigwenywe

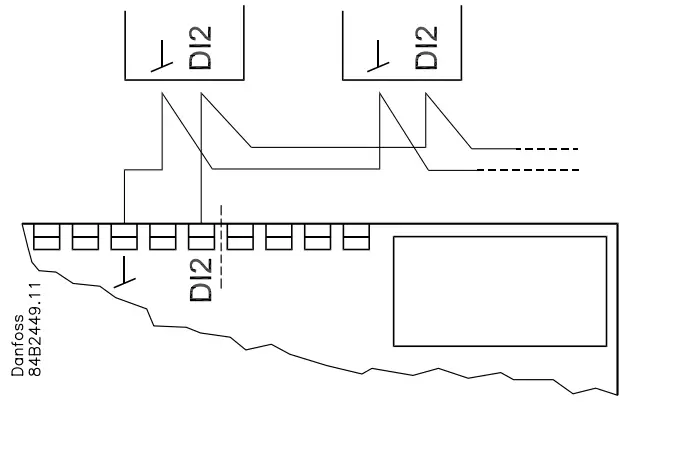

I-defrost edidiyelwe ngoxhumo lwekhebula

Izilawuli ezilandelayo zingaxhunywa ngale ndlela:

- I-AK-CC 210, AK-CC 250, AK-CC 450,

I-AK-CC 550 - Ubukhulu. 10.

Isiqandisi siqaliswa kabusha lapho zonke izilawuli “zikhulule” isignali yokuncibilika.

I-defrost edidiyelwe ngokuxhumana kwedatha

Idatha

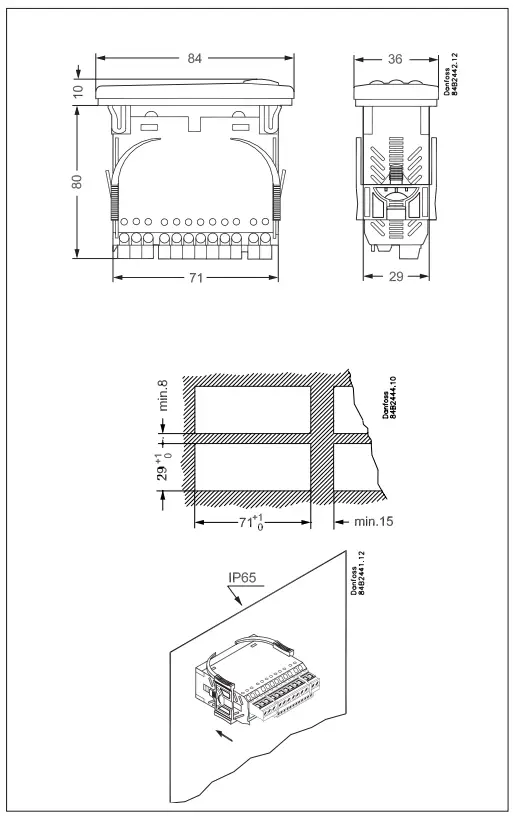

| Ukunikezwa kwevoltage | 230 V ac +10/-15 %. 2.5 VA, 50/60 Hz | ||

| Izinzwa 3 ama-pcs noma | Pt 1000 noma

I-PTC 1000 noma I-NTC-M2020 (5000 ohm / 25°C) |

||

|

Ukunemba |

Ibanga lokulinganisa | -60 kuya +99°C | |

|

Isilawuli |

±1 K ngaphansi -35°C

±0.5 K phakathi -35 kuya +25°C ±1 K ngaphezu kuka +25°C |

||

| Inzwa ye-Pt 1000 | ±0.3 K ku-0°C

±0.005 K ngegredi ngayinye |

||

| Bonisa | I-LED, amadijithi angu-3 | ||

| Isibonisi sangaphandle | EKA 163A | ||

|

Okokufaka kwedijithali |

Isiginali evela kumisebenzi yokuxhumana Izimfuneko kothintana nabo: Ubude bekhebula yokucwenga ngegolide kufanele bube bubukhulu. 15 m

Sebenzisa ama-relay asizayo uma ikhebuli iyinde |

||

| Ikhebula lokuxhuma ugesi | Ikhebula le-multi-core Max.1,5 mm2 | ||

|

Ukudluliselwa* |

CE

(250 V ac) |

UL *** (240 V ac) | |

| DO1.

Isiqandisi |

8 (6) A | 10 A I-Resistive 5FLA, 30LRA | |

| DO2. Defrost | 8 (6) A | 10 A I-Resistive 5FLA, 30LRA | |

|

DO3. Umlandeli |

6 (3) A |

6 A I-Resistive 3FLA, 18LRA

131 VA Umshayeli wendiza umsebenzi |

|

|

DO4. I-alamu |

4 (1) A

Okuncane. 100 mA** |

4 Ukungazweli

131 VA Umsebenzi wokushayela |

|

|

Imvelo |

0 kuya +55°C, Ngesikhathi sokusebenza

-40 kuya +70°C, Ngesikhathi sokuthutha |

||

| I-20 - 80% Rh, ayifinyeziwe | |||

| Akukho thonya lokushaqeka / ukudlidliza | |||

| Ukuminyana | IP65 ukusuka ngaphambili.

Izinkinobho nokupakisha kufakwe ngaphambili. |

||

| Indawo yokubalekela iwashi |

4 amahora |

||

| Izimvume

|

I-EU Low VoltagI-e Directive kanye ne-EMC ifuna ukuthi ukumakwa kwe-CE kuthotshelwe

I-LVD ihlolwe i-acc. I-EN 60730-1 kanye ne-EN 60730-2-9, A1, A2 I-EMC ihlolwe i-acc. I-EN61000-6-3 kanye ne-EN 61000-6-2 |

||

- * I-DO1 ne-DO2 ziyi-16 A ama-relay. I-8 A eshiwo inganyuswa ifike ku-10 A, lapho izinga lokushisa lendawo ligcinwa lingaphansi kuka-50°C. I-DO3 ne-DO4 ziyi-8 A ama-relay. Ubukhulu. umthwalo kumele ugcinwe.

- ** Ukufakwa kwegolide kuqinisekisa ukwenza umsebenzi ngemithwalo emincane yokuxhumana

- *** Ukugunyazwa kwe-UL okusekelwe kuma-couplings angu-30000.

U-Danfoss akakwazi ukwamukela isibopho ngamaphutha angaba khona kumakhathalogi, izincwajana nokunye okuphrintiwe. I-Danfoss igodla ilungelo lokushintsha imikhiqizo yayo ngaphandle kwesaziso. Lokhu kusebenza futhi emikhiqizweni esivele ine-oda inqobo nje uma ukushintsha okunjalo kungenziwa ngaphandle kokuba izinguquko ezilandelanayo zibe zidingekile emibhalweni osekuvunyelwene ngayo kakade.

Zonke izimpawu zokuhweba kule nto ziyimpahla yezinkampani eziqondile. I-Danfoss ne-Danfoss logotype yizimpawu zokuthengisa ze-Danfoss A/S. Wonke Amalungelo Agodliwe.

Umhlahlandlela Womsebenzisi RS8EP602 © Danfoss 2018-11

FAQ

- Q: Zingaki izinzwa ze-thermostat ezingaxhunywa kusilawuli se-AK-CC 210?

A: Kungaxhunywa izinzwa ze-thermostat ezingafika kwezimbili. - Q: Imiphi imisebenzi okokufaka kwedijithali okungasebenza?

IMP: Okokufaka kwedijithali kungasetshenziselwa ukuhlanza ikesi, ukuthintana komnyango nge-alamu, ukuqalisa umjikelezo wokuncibilika kwesithwathwa, ukumisa iqhwa okudidiyelwe, ukushintsha-shintsha phakathi kwezithenjwa zokushisa ezimbili, kanye nokudluliswa kabusha kwendawo yokuxhumana ngokuxhumana kwedatha.

Amadokhumenti / Izinsiza

|

I-Danfoss AK-CC 210 Isilawuli Sokulawula Izinga lokushisa [pdf] Umhlahlandlela Womsebenzisi I-AK-CC 210 Controller For Temperature Control, AK-CC 210, Controller For Temperature Control, For Temperature Control, Temperature Control |