I-ATIKA ASP 10 TS-2 Log Splitter

Ungawusebenzisi umshini ngaphambi kokuba ufunde imiyalelo yokusebenza, qonda wonke amanothi, futhi uhlanganise umshini njengoba kuchazwe lapha.

Ungawusebenzisi umshini ngaphambi kokuba ufunde imiyalelo yokusebenza, qonda wonke amanothi, futhi uhlanganise umshini njengoba kuchazwe lapha.

Gcina imiyalelo endaweni ephephile ukuze uyisebenzise esikhathini esizayo.

Ibanga lokulethwa

Ngemva kokukhipha, hlola okuqukethwe kwebhokisi kokuthi

- ukuphelela

- umonakalo ezokuthutha okungenzeka.

| 1 | Iyunithi yedivayisi ehlanganiswe ngaphambilini |

| 2 | Ingalo yokuzivikela |

| 3 | Ukuphepha hook |

| 4 | Umphakamisi welogi |

| 5 | Isondo |

| 6 | I-axle yesondo |

| 7 | Isondo lokusekela ezokuthutha |

| 8 | Isikhwama sokubopha |

| 9 | Imiyalelo yokusebenza |

| 10 | Ishidi lemiyalo yokuhlanganisa nokusebenza |

| 11 | Isimemezelo sewaranti |

Bika noma yimuphi umonakalo noma izinto ezingekho kumthengisi wakho, ohlinzekiwe, noma umkhiqizi ngokushesha. Izikhalazo ezenziwe ngemuva kwesikhathi ngeke zamukelwe.

Izimpawu emshinini

Funda ngokucophelela imanuwali yomsebenzisi ngaphambi komshini.

Funda ngokucophelela imanuwali yomsebenzisi ngaphambi komshini. Gqoka isivikelo sokuzwa lapho usebenza nomshini ukuze uvikele ukuzwa kwakho. Gqoka izibuko zokuphepha lapho usebenza nomshini ukuze uvikele amehlo kuma-chips nama-splinters.

Gqoka isivikelo sokuzwa lapho usebenza nomshini ukuze uvikele ukuzwa kwakho. Gqoka izibuko zokuphepha lapho usebenza nomshini ukuze uvikele amehlo kuma-chips nama-splinters. Gqoka izicathulo zokuphepha lapho usebenza nomshini ukuze uvikele izinyawo ezingodweni eziwayo.

Gqoka izicathulo zokuphepha lapho usebenza nomshini ukuze uvikele izinyawo ezingodweni eziwayo. Gqoka amagilavu okuphepha lapho usebenza nomshini ukuze uvikele izandla kuma-chips nama-splinters

Gqoka amagilavu okuphepha lapho usebenza nomshini ukuze uvikele izandla kuma-chips nama-splinters Unganethwa yimvula. Vikela kumswakama.

Unganethwa yimvula. Vikela kumswakama. Akuvunyelwe ukususa noma ukuguqula izisetshenziswa zokuvikela nezokuphepha.

Akuvunyelwe ukususa noma ukuguqula izisetshenziswa zokuvikela nezokuphepha. Kufanele isetshenziswe ngumuntu oyedwa kuphela. Gcina ababukele kanye nezilwane ezifuywayo kanye nezilwane ezifuywayo kude (ibanga eliphansi lama-5 m) ukusuka endaweni eyingozi.

Kufanele isetshenziswe ngumuntu oyedwa kuphela. Gcina ababukele kanye nezilwane ezifuywayo kanye nezilwane ezifuywayo kude (ibanga eliphansi lama-5 m) ukusuka endaweni eyingozi. Ukusika nokuchoboza ingozi! Ungalokothi uthinte izindawo eziyingozi lapho i-plitting blade ihamba.

Ukusika nokuchoboza ingozi! Ungalokothi uthinte izindawo eziyingozi lapho i-plitting blade ihamba. Gcina indawo yakho yokusebenza isesimweni esihlelekile! Ukungahlanzeki kungaholela ezingozini.

Gcina indawo yakho yokusebenza isesimweni esihlelekile! Ukungahlanzeki kungaholela ezingozini. Isexwayiso! Izingxenye zemishini ezihambayo. Hlala unaka ngokugcwele ukunyakaza kwe-blade ehlukanisayo.

Isexwayiso! Izingxenye zemishini ezihambayo. Hlala unaka ngokugcwele ukunyakaza kwe-blade ehlukanisayo. Isexwayiso! Vala injini futhi unqamule ipulaki yamapayipi ngaphambi kokwenza umsebenzi wokuhlanza, ukulungisa, noma ukulungisa.

Isexwayiso! Vala injini futhi unqamule ipulaki yamapayipi ngaphambi kokwenza umsebenzi wokuhlanza, ukulungisa, noma ukulungisa. Ungawasusi izingodo eziminyene ngezandla zakho.

Ungawasusi izingodo eziminyene ngezandla zakho. Lahla uwoyela omdala ngendlela efanele (iphuzu lokulahla uwoyela wendawo). Amafutha amadala akumele athelelwe emhlabathini noma ohlelweni lokudonsa amanzi, noma axutshwe nenye imfucuza.

Lahla uwoyela omdala ngendlela efanele (iphuzu lokulahla uwoyela wendawo). Amafutha amadala akumele athelelwe emhlabathini noma ohlelweni lokudonsa amanzi, noma axutshwe nenye imfucuza. Veza isistimu ye-hydraulic ngaphambi kokufaka isihlukanisi selogi ku-opera-tion. (bona "Ukuqala")

Veza isistimu ye-hydraulic ngaphambi kokufaka isihlukanisi selogi ku-opera-tion. (bona "Ukuqala") Iphoyinti lokubopha

Iphoyinti lokubopha Iphuzu lokuphakamisa

Iphuzu lokuphakamisa Qiniseka ukuthi injini ijikela endaweni efanele (bona umcibisholo wemoto) ngoba ukusebenza ngendlela engafanele kulimaza iphampu kawoyela. (bona "Ukuqala")

Qiniseka ukuthi injini ijikela endaweni efanele (bona umcibisholo wemoto) ngoba ukusebenza ngendlela engafanele kulimaza iphampu kawoyela. (bona "Ukuqala")- Lo mkhiqizo uhambisana nemithetho yaseYurophu esebenza kuwo.

Imishini kagesi ayingeni kudoti wasekhaya.

Nikeza amadivayisi, izinsiza, kanye nokupakisha ekugayweni kabusha kwe-eco-friendly.

Ngokuya nge-European Directive 2012/19/EU mayelana nezinsalela zikagesi neze-elekthronikhi, izinto zikagesi ezingasaseviseke kufanele ziqoqwe ngokuhlukana futhi zilethwe endaweni ukuze zigaywe kabusha ezihambisana nemvelo.

Bona Ukusebenza ngesihlukanisi selogi

Bona Ukusebenza ngesihlukanisi selogi

Izimpawu zokusebenza imiyalelo

Ingozi engaba khona noma isimo esiyingozi. Ukwehluleka ukugcina le miyalo kungaholela ekulimaleni noma kubangele ukulimala kwempahla.

Ingozi engaba khona noma isimo esiyingozi. Ukwehluleka ukugcina le miyalo kungaholela ekulimaleni noma kubangele ukulimala kwempahla. Ukugcina lolu lwazi olubalulekile eziqondisweni ezifanele kuholela ekungasebenzini kahle. ndling. Ukwehluleka

Ukugcina lolu lwazi olubalulekile eziqondisweni ezifanele kuholela ekungasebenzini kahle. ndling. Ukwehluleka Ulwazi lomsebenzisi. Lolu lwazi lukusiza ukuthi ulusebenzise

Ulwazi lomsebenzisi. Lolu lwazi lukusiza ukuthi ulusebenzise- Ukuhlanganisa, ukusebenza, kanye nokusevisa Lapha uchazwa kahle ukuthi yini okumele uyenze.

Amanothi abalulekile okuziphatha okuhambisana nemvelo. Ukwehluleka ukugcina le miyalo kungaholela ekulimaleni kwemvelo.

Amanothi abalulekile okuziphatha okuhambisana nemvelo. Ukwehluleka ukugcina le miyalo kungaholela ekulimaleni kwemvelo.- Sicela ubheke ishidi leziyalezo elinamathiselwe kanye nokusebenza ukuze uthole izinkomba zezinombolo embhalweni.

Ukusetshenziswa okuhlosiwe okujwayelekile

- Isihlukanisi selogi kufanele sisetshenziselwe kuphela ukuhlukanisa izingodo.

- Isihlukanisi selogi sisebenza kuphela ekusetshenzisweni kwangasese emkhakheni wendlu nokuzilibazisa.

- Izingodo eziqondile kuphela ezifanele ukusetshenziswa nesihlukanisi selogi

- Izingxenye zensimbi (izinzipho, ucingo, njll.) kufanele zikhishwe ezingodweni ngaphambi kokuhlukaniswa.

- Ukusetshenziswa okuhlosiwe kuhlanganisa nokuhambisana nemibandela yokusebenza, yokusevisa, neyokulungisa enqunywe umenzi nokulandela imiyalelo yokuphepha efakwe emiyalweni.

- Imithetho efanele yokuvimbela izingozi yokuhlinzwa kanye neminye imithi evunyiwe ngokujwayelekile kanye nemithetho yokuphepha kufanele kuthotshelwe.

- Zonke ezinye izinhlobo zokusebenzisa zibhekwa njengokungafaneleki. Umkhiqizi akamukeli sikweletu sanoma yimuphi umonakalo obangelwa ukusetshenziswa okungafanele, futhi noma iyiphi ingozi kulesi simo ithwalwa umsebenzisi kuphela.

- Ukulungiswa okungagunyaziwe kusihlukanisi selogi akubandakanyi isibopho sezomthetho somkhiqizi ngomonakalo wanoma yiluphi uhlobo oluvela kukho.

- Abantu abajwayelene nedivayisi kuphela nabanolwazi mayelana nezingozi ezingaba khona abavunyelwe ukulungisa, ukusebenzisa, kanye nokusevisa lolu cingo. Imisebenzi yokulungisa ingenziwa yithi kuphela noma i-ejenti yesevisi yamakhasimende ekhethwe yithi.

Izingozi ezisele

- Ngisho noma isetshenziswe kahle, ubungozi obuyinsalela bungaba khona ngisho noma kuthotshelwa izimiso zokuphepha ezifanele ngenxa yomklamo onqunywa inhloso ehlosiwe.

- Izingozi ezisalelayo zingancishiswa uma “iseluleko sezokuphepha kanye “nokusetshenziswa okuhlosiwe” kanye nayo yonke imiyalelo yokusebenza kugcinwa.

- Ukugcina le miyalo, nokunakekela okufanele, kuzonciphisa ingozi yokulimala komuntu noma ukulimala kwezinto zokusebenza.

- Ingozi yokulimala ngenxa yezingcezu zokhuni ezikhishiwe.

- Ingozi yokulimala ezinyaweni ngenxa yokuwa kokhuni

- Ingozi yokulimala eminwe lapho ukhipha izingcezu zokhuni eziminyene

- Ukungathobeli imiyalelo yokuphepha kungase kubangele ukulimala komqhubi noma umonakalo wempahla.

- Ukunganaki, ukwehluleka ukuthobela imithetho yezokuphepha, kanye nokusetshenziswa okungalungile kungaholela ekulimaleni ezandleni naseminweni yakho lapho i-blade ehlukanisayo isusa izingozi kugesi uma usebenzisa izixhumo zikagesi ezingafanele.

- Ukuthinta izingxenye ezibukhoma zezingxenye zikagesi ezivuliwe.

- Ingozi yomlilo kanye nokushelela ngokuvuza uketshezi olusebenza ngehydraulic.

- Ukonakala kokuzwa lapho usebenza emshinini isikhathi eside ngaphandle kokuvikelwa kwendlebe.

- Ngaphezu kwalokho, naphezu kwazo zonke izinyathelo zokuphepha ezithathiwe, ubungozi bensalela obungabonakali busengaba khona.

Imiyalo yokuphepha

Ngaphambi kokuqala le divayisi, funda futhi ugcine izeluleko ezilandelayo. Futhi, gcina imithetho yokuvikela yenhlangano yakho yobungcweti kanye nezinhlinzeko zokuphepha ezisebenza ezweni elifanele, futhi uzivikele wena nabanye ekulimaleni okungenzeka.

- Dlulisa imiyalelo yokuphepha kubo bonke abantu abasebenza

- Gcina le miyalo yokuphepha endaweni ephephile.

- Abantu abasebenza ngokuhlukanisela izinkuni kumele ngabe bathole imiyalelo efanele mayelana nomsebenzi ohlosiwe futhi bajwayele ukusetshenziswa kwesihlukanisi sezinkuni kanye nemiyalelo yokuphepha.

- Zenze ujwayele imishini ngaphambi kokuyisebenzisa, ngokufunda nokuqonda imiyalelo yokusebenza.

- Ungawusebenzisi umshini ngezinjongo ezingafanele (bona okuthi “Ukusetshenziswa okuhlosiwe Okungavamile” kanye nokuthi “Ukusebenza ngesihlukanisi selogi”).

- Qaphela. Qaphela. Naka lokho okwenzayo. Qala ukusebenza ngokunengqondo. Ungalusebenzisi ucingo lapho ukhathele noma udakwe izidakamizwa, utshwala, noma izinkomba Umzuzu owodwa wokunganaki lapho usebenzisa ucingo ungaholela ekulimaleni okubi kakhulu.

- Izingane kanye nabantu abasha abangaphansi kweminyaka engu-18 ubudala kanye nabantu abangakayifundi incwadi yeziqondiso abavunyelwe ukusebenzisa lo mkhiqizo.

- Ungalokothi usebenze ngenkathi abantu, ikakhulukazi izingane ezincane, noma izilwane ezifuywayo ziseduze nawe.

- Ungavumeli abanye abantu, ikakhulukazi izingane, ukuthinta ithuluzi noma injini.

Imishini yokuzivikela yomuntu siqu

- Ungalokothi usebenze ngaphandle kwezinto zokuvikela ezifanele.

- Ungagqoki izingubo ezixegayo noma ubucwebe; babengabanjwa izingxenye ezihambayo.

- I-Hairnet uma kunezinwele ezinde

- ukuvikela amehlo nezindlebe

- Izicathulo eziqinile ezinamakepisi okuvikela uzwane (izicathulo zokuphepha)

- Amabhulukwe amade

- amagilavu okuzivikela

- Impahla yosizo lokuqala

- Umakhalekhukhwini uma kudingeka

Imiyalelo yokuphepha - ngaphambi kokusebenza

Yenza lokhu kuhlola okulandelayo ngaphambi kokuqala futhi njalo ngesikhathi sokusebenza. Bheka izigaba ezifanele encwadini yeziqondiso zokusebenza:

- Ingabe idivayisi ihlanganiswe ngokuphelele futhi ngendlela efanele?

- Ingabe idivayisi isesimweni esihle nesiphephile?

- Ingabe izibambo zihlanzekile futhi zomile?

- Ngaphambi kokuqala umsebenzi wakho qiniseka ukuthi:

- abekho abanye abantu, izingane, noma izilwane ezihlala endaweni yokusebenza,

- ungahlala uhlehla ngaphandle kwezithiyo,

- uhlale unendawo yokuma evikelekile.

- Ingabe indawo yokusebenza ayinazo izingozi zokukhubeka? Gcina indawo yakho yokusebenza isesimweni esihlelekile! Ukungahlanzeki kungaholela ezingozini -Ingozi yokukhubeka!

- Cabangela imithelela yezemvelo:

- Ungasebenzi ngaphansi kwezimo zokukhanya ezinganele (isb. inkungu, imvula, ukukhuphuka kweqhwa, noma ukuhwalala).

- Ungasebenzi ezimeni zesimo sezulu esingesihle (isb. ingozi yemvula ewumbani, iqhwa).

- Ungawusebenzisi lo mshini eduze koketshezi oluvuthayo noma amagesi

- Umsebenzisi unesibopho sezingozi noma izingozi ezenzeka kwabanye abantu noma izakhiwo zabo.

- Qinisekisa ukuthi umi endaweni evikelekile futhi ugcina ibhalansi yakho ngaso sonke isikhathi.

- Ungawushintshi umshini noma izingxenye zawo.

Imiyalelo yokuphepha – ukusebenza

- Thatha indawo yokusebenza eseduze nezilawuli.

- Ungalokothi ume phezu komshini.

- Vala idivayisi uma uthatha ikhefu ukuze kungabikho muntu osengozini. Vikela idivayisi ekufinyeleleni okungagunyaziwe.

Izaziso zokuphepha zezihlukanisi zezinkuni

- Isihlukanisi selogi singasetshenzwa umuntu oyedwa kuphela.

- Ungalokothi uzame ukuhlukanisa izingodo eziqukethe izinzipho, izintambo, noma ezinye izinto ezifanayo.

- Sezivele zihlukanise izinkuni kanye nezicucu zezinkuni kudala indawo yokusebenza eyingozi. Umsebenzisi angase akhubeke, ashelele, noma awe. Njalo gcina indawo yokusebenza icocekile.

- Ungalokothi ubeke izandla phezu noma eduze kwanoma yiziphi izingxenye ezinyakazayo zomshini uma ukhanyisa.

- Izinkuni ezihlukanisiwe kuphela ezihambisana nobukhulu okufanele zicutshungulwe.

Imiyalelo yokuphepha – ngenkathi usebenza

- Ungalokothi usebenze wedwa. Gcina ukuxhumana okuzwakalayo nokubonakalayo nabanye abantu ngaso sonke isikhathi ukuze uvumele usizo lokuqala olusheshayo ezimeni eziphuthumayo.

- Misa injini ngokushesha ezingozini eziseduze noma ezimweni eziphuthumayo.

- Ungalokothi ushiye idivayisi isebenza ingagadiwe.

- Yeka ukusebenza ngokushesha lapho uzizwa ungaphilile (isb. ikhanda elibuhlungu, isicanucanu, njll.). Uma kungenjalo, kukhona ingozi eyengeziwe yezingozi.

- Ungalayishi umshini kakhulu! Usebenza kangcono futhi uphephile ebangeni lokusebenza elinikeziwe.

- Thatha ikhefu uma usebenza ukuze injini iphole.

Ukuziphatha esimweni esiphuthumayo

- Qala zonke izinyathelo zosizo lokuqala ezidingekayo ezifanele ukulimala futhi ufune iseluleko sezokwelapha esifanelekayo ngokushesha ngangokunokwenzeka.

- Vikela umuntu olimele ekulimaleni okwengeziwe futhi uvale amandla omuntu olimele.

Imiyalelo yokuphepha ejwayelekile

- Sebenzisa umshini, izesekeli, amathuluzi, njll. ngokuhambisana nale miyalo. Lapho wenza kanjalo cabangela izimo zokusebenza kanye nomsebenzi okufanele wenziwe. Ukusetshenziswa komshini kwezinye izinhlelo zokusebenza ezihlosiwe kungase kubangele izimo eziyingozi.

- Ungafutha umshini ngamanzi. (umsuka wengozi kagesi).

- Ungawushiyi umshini umile emvuleni noma uwusebenzise uma lina.

Nakekela umshini ngokucophelela:

- Landela imiyalelo yesondlo.

- Gcina izibambo zomile futhi zingenawo uwoyela, inhlaka, namafutha. Hlola umshini ngomonakalo ongaba khona:

- Ngaphambi kokuqhubeka nokusebenzisa umshini, amadivaysi okuphepha kufanele abhekwe ngokucophelela ukuthi ayasebenza yini futhi ahlosiwe. Sebenzisa kuphela idivayisi ngezinto zokuphepha eziphelele nezinamathiselwe ngendlela efanele futhi ungashintshi lutho ocingweni olungaphazamisa ukuphepha kwalo.

- Hlola ukuthi izingxenye ezinyakazayo zisebenza kahle yini futhi azinamatheli noma izingxenye zonakele. Zonke izingxenye kufanele zifakwe kahle futhi zigcwalise zonke izimo ukuze kuqinisekiswe ukusebenza okuphelele.

- Imishini yokuphepha eyonakele kanye nezingxenye kufanele kulungiswe kahle noma kushintshwe ishabhu eyaziwayo, eyisingcweti; njengoba kungekho okunye okushiwo emiyalweni yokusetshenziswa.

- Amalebula okuphepha awonakele noma angabonakali kufanele kushintshwe.

- Ungavumeli noma yimuphi ukhiye wethuluzi ukuthi uxhunywe! Ngaphambi kokuvula, hlola njalo ukuthi wonke amathuluzi asusiwe.

- Gcina impahla engasetshenziswanga endaweni eyomile, ekhiyiwe lapho izingane zingafinyeleleki khona.

- Vala umshini bese ukhipha ipulaki ye-mains kusokhethi lapho

- Ukwenza umsebenzi wokulungisa.

- Ukwenza umsebenzi wokulungisa nokuhlanza.

- ukukhawulela amaphutha.

- ukuhlola izintambo zokuxhuma ukuthi zigwinywe noma zonakele

- Isitoreji kanye nezokuthutha

- Ukuhamba kungagadiwe (ngisho nangesikhathi sokuphazamiseka okufushane).

- Ungayenzi imisebenzi yokulungisa emshinini ngaphandle kwaleyo echazwe esigabeni “Ukulungisa” kodwa xhumana nomkhiqizi noma izikhungo ezigunyaziwe zesevisi yamakhasimende.

- Ukulungiswa kwezinye izingxenye zomshini kufanele kwenziwe ngumkhiqizi noma enye yezindawo zakhe zesevisi yamakhasimende.

- Sebenzisa kuphela izingxenye ezisele zangempela kanye nezingxenye ezisetshenziswayo. Izingozi zingavela kumsebenzisi ngokusebenzisa ezinye izingxenye eziyisipele. Umkhiqizi akanasibopho sanoma yimuphi umonakalo noma ukulimala okubangelwa isenzo esinjalo.

Ukuphepha kukagesi

- Idizayini yekhebula yokuxhuma ngokuya nge-IEC 60245 (H 07 RN-F) enengxenye ewumgogodla yokuwela okungenani

5 x 1.5 mm² ngobude bekhebula obukhulu obufika ku-10 m Ungalokothi usebenzise umshini onentambo yokunikezela amandla engaphezu kuka-10 m ubude. Izintambo zikagesi ezinde zizodala ivolumutage drop the motor ngeke ikwazi ukunikeza ukusebenza kwayo okuphezulu kanye nokusebenza komshini kuzophazamiseka.

5 x 1.5 mm² ngobude bekhebula obukhulu obufika ku-10 m Ungalokothi usebenzise umshini onentambo yokunikezela amandla engaphezu kuka-10 m ubude. Izintambo zikagesi ezinde zizodala ivolumutage drop the motor ngeke ikwazi ukunikeza ukusebenza kwayo okuphezulu kanye nokusebenza komshini kuzophazamiseka. - Amapulagi kanye nezindawo zokuxhumanisa ezintanjeni zokuxhuma kufanele zenziwe ngerabha, i-PVC engaqinile, noma enye impahla ye-thermoplastic yokuqina kwemishini efanayo noma embozwe ngale nto.

- Isixhumi sekhebula lokuxhuma kufanele sibe nobufakazi bokuchaphaza. Lapho ufaka ikhebula lokuphakela amandla qaphela ukuthi ayiphazamisi, ayiminyanisiwe, futhi ukuxhuma kwepulaki akumanzi.

- Vala ikhebula ngokuphelele uma usebenzisa isigubhu sekhebula. Ungayisebenzisi ikhebula ngezinjongo ezingahloselwe zona. Vikela ikhebula ekushiseni, kuwoyela, nasezinqeni ezicijile. Ungasebenzisi ikhebula ukudonsa ipulaki kusokhethi.

- Hlola njalo izintambo zokunweba bese uzishintsha uma zonakele.

- Ungasebenzisi noma yiziphi izintambo zokuxhuma ezinokukhubazeka.

- Lapho usebenza ngaphandle, sebenzisa kuphela izintambo ezinwetshiwe ezigunyazwe ngokukhethekile futhi zilebulwe ngokufanelekile ukuthi zisetshenziswe ngaphandle.

- Ungalumisi noma yikuphi ukuxhunywa kukagesi kwesikhashana.

- Ungalokothi udlule izinto ezivikelayo noma uzenze zingasebenzi.

- Ukuxhunywa kukagesi noma ukulungiswa kwezingxenye zikagesi zomshini kufanele kwenziwe umuntu osebenza ngogesi onesitifiketi esisodwa sezindawo zethu zesevisi yamakhasimende. Imithetho yendawo - ikakhulukazi mayelana nezinyathelo zokuvikela - kufanele igcinwe.

Incazelo yedivayisi / izingxenye ezisele

Sicela ubheke ukuhlanganiswa okunamathiselwe kanye neshidi elisebenzayo lokusebenza.

Umhlangano

- Xhuma isihlukanisi sezinkuni ohlelweni lokuphakela amandla kuphela ngemva kokuqeda ukuhlanganisa okuphelele.

- Faka amasondo, ingalo yokuvikela, ihuku lokuphepha, ugodo file, r, kanye nesondo lokusekela ezokuthutha njengoba kuboniswe kuMfanekiso 2 - 9 kumhlangano kanye neshadi lokusebenza.

- Qinisekisa ukuthi ngemuva kokukhweza ukuthi zonke izikulufa ziqiniswe ngokuqinile.

Indawo

- Ungawusebenzisi umshini endaweni eqondile yamapayipi egesi noma kaphethiloli noma iziqukathi, nanoma yiziphi ezinye izinto ezivutha kalula.

- Umshini kufanele ubekwe ngokuzinza endaweni eqinile neyisicaba (njengephansi likakhonkolo). Ukuqinisekisa ukuzinza, kuyadingeka ukugoqa umshini ngama-dowels amabili nezikulufu (okungenani i-M12 x 160) phansi.

Ukugunyaza

- Hlola ukuthi umshini uhlanganiswe ngokuphelele futhi ngendlela efanele

- Ngaphambi kokusetshenziswa ngakunye, hlola

- Izintambo zokuxhuma zokukhubazeka (imifantu, ukusikeka, njll.).

- Ungayisebenzisi into engalungile akukho monakalo emshinini (bona "imiyalelo yokuphepha")

- zonke izikulufu ziqinile.

- hlola isistimu ye-hydraulic ukuze uthole noma yikuphi ukuvuza okungenzeka

- amapayipi kanye nokufakwa kwe-hydraulic

- imishini yokuvala

- izinga lamafutha

Ukopha

- Veza isistimu ye-hydraulic ngaphambi kokufaka isihlukanisi selogi ekusebenzeni.

- Khumula isivalo sikawoyela (22) ngokujika izikhathi eziningana ukuze umoya uphume ethangini likawoyela.

- Shiya isivalo samafutha sivuliwe ngesikhathi sokusebenza.

- Vala isivalo samafutha ngaphambi kokuhambisa isihlukanisi selogi, njengoba kungenjalo, uwoyela we-othe uzovuza kuleli phuzu.

- Uma i-hydraulic system ingangeni, umoya obanjwe uzolimaza izimpawu futhi ubangele umonakalo unomphela ku-splitter yelogi.

Ukuxhumana okuyinhloko

- Qhathanisa i-voltage inikezwe epuleti lemodeli yomshini elinamapayipi amakhulutage futhi uxhume umshini kupulaki efanele futhi enobumba ngokufanelekile.

- Sebenzisa kuphela amakhebuli anwetshiwe anesiphambano esiyisisekelo esanele.

- Xhuma umshini ngeswishi yokuphepha enephutha engu-30 mA.

- Ukuvikelwa kwe-fuse: 16 A isikhathi-lag

![]() Iyavula:

Iyavula:

Cindezela inkinobho eluhlaza.

![]() Iyacisha

Iyacisha

Cindezela inkinobho ebomvu.

Ngaphambi kokusetshenziswa ngakunye, hlola umsebenzi womshini wokunqamula (ngokuvula nokuvala). Ungasebenzisi noma iyiphi idivayisi lapho iswishi ingakwazi ukuvulwa futhi ivalwe khona. Amaswishi alimele kufanele alungiswe noma ashintshwe ngokushesha yisevisi yamakhasimende.

Qala kabusha ukuvikela uma kwenzeka ukwehluleka kwamandla (zero-voltagumqalisi)

- Okokusebenza kuzocisha ngokuzenzakalelayo uma kukhona ukunqanyulwa kukagesi. Cindezela inkinobho eluhlaza ukuze uyivule futhi.

Isihlukanisi selogi ne-400 V a3~

![]() Qiniseka ukuthi injini ijikela endaweni efanele (bona umcibisholo wemoto) ngoba ukusebenza ngendlela engafanele kulimaza iphampu kawoyela.

Qiniseka ukuthi injini ijikela endaweni efanele (bona umcibisholo wemoto) ngoba ukusebenza ngendlela engafanele kulimaza iphampu kawoyela.

Hlola isiqondiso sokuzungezisa:

- Qala injini.

- Sebenzisa zombili izibambo zokusebenza, i-blade ehlukanisayo ihlehla.

- Uma i-blade ehlukanisayo isivele isendaweni ephansi kunazo zonke: sebenzisa i-lever yokubuyisela, futhi i-blade ehlukanisayo iya phezulu.

- Uma i-blade ehlukanisayo inganyakazi, cisha injini bese ushintsha isiqondiso sokujikeleza.

Ungashintsha isiqondiso ngokubeka i-screwdriver ku-slot ehlinzekwe kukhola yepulaki, futhi ulungise inkomba efanele n ukuya ohlelweni lokusebenza kwesokunxele noma kwesokudla kanye nokulala ingcindezi kancane.

Ama-hydraulics

Hlola imigqa namapayipi amanzi ngaphambi kokusebenzisa ngakunye.

- Ungalokothi usebenzise umshini uma kwenzeka kuba nengozi engaba khona oketshezini olusebenza ngamanzi.

- Qinisekisa ukuthi umshini nendawo yokusebenza ihlanzekile futhi ayinawo uwoyela.

- Ingozi yokushelela noma umlilo!

- Hlola i-hydraulic reservoir njalo ukuze uqiniseke ukuthi iqukethe uwoyela we-hydraulic owanele (bheka “Ukunakekela Nokunakekela).

Ukusebenza ne-log splitter

Yiziphi izingodo engingazihlukanisa?

Usayizi wezingodo

- Ubude belogu ubuncane. 560 - ubuningi. 1040 mm

- Ubukhulu belogu ubuncane. 100 - ubuningi. 300 mm

Ububanzi belogi kuwumhlahlandlela onconywayo, ngoba: izingodo ezincane zingaba nzima ukuhlukana uma ziqukethe amafindo noma uma imicu iqine kakhulu. Ungazami ukuhlukanisa izingodo eziluhlaza. Izingodo ezomile kulula kakhulu ukuhlukana ngazo futhi azibangeli ukujama kaningi njengohlaza (damp) ukhuni.

- Ukuqina kokhuni oluqinile: Sebenzisa ukuqaphela okukhulu! Qaphela ukuthi izinkuni ezinamafindo zingaqhuma zivuleke. Ungalokothi uhlukanise ukhuni olungakanqunywa ngaphambili.

Imiyalo ekhethekile yokuhlukanisa izingodo:

Amalungiselelo

Amalogi azohlukaniswa kufanele asikwe abe ubukhulu obukhulu. Qinisekisa futhi ukuthi izingodo zisikwe ziqonde futhi isikwele. Izinkuni ezineziphetho ezitshekile zingashelela ngesikhathi sokuhlukana. Beka ilogi ngendlela efanele ku-splitter yelogi, ukuze ungabangeli noma iyiphi ingozi yokukhubeka noma ukuwela ku-opharetha. Hlola ngaphambi kokuhlukanisa ukuthi ikholomu ehlukanisayo igcotshwe ngokwanele yini ukuvumela ukuhoxiswa nokunwetshwa okungenazinkinga.

Isebenza

Isebenza

Ukusebenza kwezandla ezimbili

- Lesi sihlukanisi selogi sizosetshenziswa umuntu oyedwa. Ungalokothi uvumele abantu ababili noma ngaphezulu ukuthi basebenzise lesi sihlukaniso samalogi.

- Ungalokothi uvimbele izibambo zokulawula.

- Cindezela inkinobho eluhlaza kumotho kagesi. Linda isikhashana kuze kube yilapho injini isifinyelele izinguquko zayo zokusebenza futhi nomfutho odingekayo sewakhiwe ku-hydrauliccump. Hlola isiqondiso semoto kusihlukanisi selogi nge-eephase motor (400 V 3~), ngoba ukusebenza ngendlela engafanele kulimaza iphampu kawoyela.

- Cindezela phansi isibambo sokusebenza ngakwesobunxele (12) kuze kube yilapho ulogi lubanjwe uzipho lokulungisa (14). Lungisa uzipho lokulungisa ngokuya ngobude belogi. Khulula isikulufu sephiko (A) bese ulungisa uzipho lokulungisa.

- Cindezela futhi ubambe isibambo sokusebenza kwesokunxele (12) bese ucindezela isibambo sokusebenza kwesokudla (13) phansi siye kuhhafu ukuze uhlukanise ilogu kancane kancane kuqala.

- Bese ucindezela isibambo sokulawula esingakwesokudla phansi ukuze uhlukanise ilogu kuze kube sekupheleni.

Inqubo yokuhlukanisa

- Ngesibambo sokusebenza esilungile (13) ungalungisa amandla ahlukanisayo ngokohlobo lokhuni:

- Amandla amakhulu okuhlukanisa ngesivinini esiphansi sokuhlukanisa ikakhulukazi amalogi aqinile noma agciniwe noma ekuqaleni kwenqubo yokuhlukanisa indawo emaphakathi yesibambo sokusebenza.

- Isivinini esikhulu sokuhlukanisa esinamandla aphansi ahlukanisayo wokuhlukanisa izingodo ezivamile noma ekupheleni kwenqubo yokuhlukanisa indawo ephansi yesibambo sokusebenza.

Reverse

- Cindezela phansi i-return lever (25) kuze kube yilapho i-blade ehlukanisayo (17) isendaweni ephakeme kakhulu futhi.

Ngaphambi kokusebenzisa ngakunye, qiniseka ukuthi izibambo ezisebenzayo zisebenza kahle.

Ukulungisa ukuphakama kwe-stroke

Endabeni yezingcezu zezinkuni ezimfushane, ukusebenza kahle kungandiswa ngokunciphisa ukubuya komsiki wokuhlukanisa.

- Beka ilogu ku-base plate bese wehlisa i-blade ehlukanisayo ku-approx. 2 cm ukusuka kulogi ngokucindezela phansi izibambo ezimbili zokusebenza.

- Khipha izibambo zokusebenza ukuze i-blade ehlukanisayo ihlale kule ndawo futhi ucime iyunithi.

- Akhiphe amandla.

- Nciphisa indlela yokubuya endukwini efakwe eceleni ngokulungisa isikulufu sokubamba ekuphakameni okudingekayo.

Umphakamisi welogi

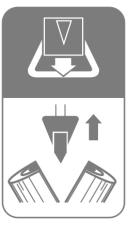

![]() Ungasebenzisa isiphakamisi sogodo ukuze uphakamise ugodo ngezicucu ezinkulu nezisindayo.

Ungasebenzisa isiphakamisi sogodo ukuze uphakamise ugodo ngezicucu ezinkulu nezisindayo.

- Khipha ihuku lokuphepha (3) kumphakamisi wogodo (4).

- Manje yehlisa ummese ohlukanisayo kuze kube yilapho umphakamisi welogi ephansi.

- Manje beka ilogi kusiphakamisi selogi bese uvumela i-blade ehlukanisayo ikhuphuke futhi.

- Manje usungakwazi ukubeka ilogu ku-base plate.

Ukuhlukanisa izingodo:

- Beka ilogu ukuze ihlukaniswe iqonde ku-base plate.

- Qinisekisa ukuthi ilogi isezingeni futhi izimele ngokuzimela ku-base plate. Ungalokothi uzame ukuhlukanisa ilogi ngokulinganayo uhlukanise izingodo ngendlela yezintambo zokhuni. Umshini ungalimala uma uzama ukuhlukanisa izinkuni phakathi kokusanhlamvu.

- Qinisekisa ukuthi uzipho lokulungisa (14) lulungiswa ngokuya ngobude belogi.

- Huka ihhuku yokuphepha kusiphakamisi selogi.

- Susa izingcezu zokhuni ezihlukanisiwe endaweni yakho yokusebenza eqondile. Lokhu kusiza ukugwema izingozi.

- Ungalokothi uzame ukuhlukanisa izingodo ezimbili ngesikhathi esisodwa.

- Ungalokothi uzame ukususa noma ukufaka esikhundleni ilogu phakathi nenqubo yokuhlukanisa.

Ungalokothi uzame ukuphoqa ukuhlukaniswa kwelogi ngokugcina ingcindezi imizuzwana embalwa. Lokhu kungaholela ekulimaleni komshini. Misa ilogu futhi ku-base plate bese uphinda umsebenzi wokuhlukanisa noma ubeke ilogu ohlangothini olulodwa.

Indlela yokukhipha i-log eminyene?

Kunengozi yokuthi izingodo ezinamafindo zibambeke phakathi nenqubo yokuhlukanisa.

- Vala umshini bese unqamula amandla.

- Ungawasusi izingodo eziminyene ngezandla zakho.

- Hambisa kahle ugodo olunamathele nge-crowbar emuva naphambili Ungalimazi insika ehlukanisayo.

- Ungalokothi ufake isando kulogi enamathele.

- Ungalokothi usebenzise isaha ukuze usike ugodo olubhajiwe ngaphandle komshini hhayi ukucela usizo lomuntu wesibili - lona umsebenzi womuntu oyedwa.

Ukuqeda umsebenzi:

- Hambisa i-blade ehlukanisayo uye endaweni ephezulu kakhulu (isimo esihoxisiwe).

- Vala umshini futhi unqamule ipulaki ye-mains.

- Landela imiyalelo yokunakekelwa kanye nesondlo.

Isondlo nokunakekelwa

Ngaphambi komsebenzi ngamunye wokulungisa nowokuhlanza Cisha ucingo.

Ngaphambi komsebenzi ngamunye wokulungisa nowokuhlanza Cisha ucingo.- Khipha ipulaki yamandla.

Umsebenzi wokulungisa nokulungisa ngaphandle kwalowo ochazwe kulesi sahluko uvunyelwe kuphela ukuba wenziwe ngabasebenzi benkonzo. Ukuze kugcinwe futhi kuhlanzwe, izisetshenziswa zokuphepha ezikhishiwe kufanele zigxunyekwe ngokufanelekile futhi zifakazelwe futhi. Sebenzisa izingxenye ezisele zangempela kuphela. Ngaphandle kwezingxenye zangempela kungase kubangele umonakalo nokulimala okungalindelekile. Qiniseka ukuthi ususa noma imaphi amathuluzi emshinini ngemva kokuphothula umsebenzi wesevisi.

Gqoka amagilavu okuzivikela ukuze ugweme ukulimala ezandleni.

Qaphela okulandelayo ukuze ugcine isihlukanisi selogi sisebenza kahle:

- Hlanza umshini kahle ngemva kokuqeda ukuwusebenzisa.

- Susa noma yiziphi izinsalela emshinini.

- Hlola izinga lamafutha bese ushintsha amafutha njengoba kudingeka.

- Hlola idivayisi ukuze uthole amaphutha asobala njenge

- izakhi zokubopha okuxekethile

- izingxenye ezigugile noma ezilimele

- izembozo ezihlanganiswe kahle nezingenasici kanye nemishini yokuzivikela.

- Hlola amapayipi adonsa amanzi kanye noxhumo lwepayipi njalo ukuze uthole noma yikuphi ukuvuza nokufakwa okuqinile.

- Gcoba ikholomu ehlukanisayo (18) njalo noma uyigcobe usebenzisa uwoyela wesifutho ongavumelani nemvelo.

Ukulola inkezo ehlukanisayo

Ngemuva kwezikhathi ezinde zokusebenza, ukuze kuncishiswe ukusebenza okuhlukanisayo noma ukuwohloka okuncane konqenqema lokusika, gaya i-blade ehlukanisayo noma uyilole ngenhlawulo. file (susa ama-burrs).

Ngilihlola kanjani izinga likawoyela?

- Ikholomu ehlukanisayo kumelwe ibe sesimweni sokugijima.

- Khumula i-dipstick yamafutha.

- Hlanza i-dipstick ne-oil seal.

- Khwebula i-dipstick yamafutha uyibuyisele endaweni evulekile bese uyiqinisa.

- Khumula i-dipstick yamafutha futhi.

- Izinga likawoyela kufanele libe phakathi kuka-MIN kanye no-MAX.

Gcwalisa uhlobo olufanayo lwamafutha uma izinga liphansi kakhulu (MIN noma ngaphansi).

Gcwalisa uhlobo olufanayo lwamafutha uma izinga liphansi kakhulu (MIN noma ngaphansi).

- Hlola uphawu lwamafutha bese ulubuyisela esikhundleni uma lonakaliswe nganoma iyiphi indlela.

- Faka esikhundleni i-dipstik endaweni yokugcina uwoyela.

- Khipha i-dipstick ngokuphenduka okumbalwa ukuze uvumele umoya ukuba uphume ethangini likawoyela.

Kufanele ngiwashintshe nini uwoyela?

Ushintsho lokuqala lwamafutha kufanele lwenziwe ngemuva kwamahora angama-50 okusebenza, bese kuthi njalo ngamahora angama-500.

- Kudingeka abantu ababili.

![]() Ukushintsha amafutha:

Ukushintsha amafutha:

- Ikholomu ehlukanisayo kumelwe ibe sesimweni sokugijima.

- Khumula i-dipstick yamafutha.

- Beka isitsha ngaphansi kwesihlukanisi selogi ukuze ubambe amafutha amadala. Isitsha kufanele sibe namandla okungenani ama-3. amalitha.

- Khipha ipulaki yokudonsa amanzi (29) ukuze uwoyela uphume.

- Wonke uwoyela ngeke uphele kodwa insalela izohlala ekujikelezweni kwamafutha.

- Faka uphawu bese ukhipha ipulaki futhi.

- Thela uwoyela omusha wehydraulic (Ubuningi, bheka “Idatha Yobuchwepheshe”) usebenzisa ifaneli ehlanzekile.

Gcwalisa amafutha kancane futhi ungafaki kanyekanye. Hlola izinga likawoyela phakathi.

Ungalokothi ugcwalise amafutha amaningi kakhulu. - Hlanza i-dipstick ne-oil seal.

- Hlola uphawu lwamafutha bese ulubuyisela esikhundleni uma lonakaliswe nganoma iyiphi indlela.

- Faka i-dipstick esikhundleni se-oil reservoir.

- Khipha i-dipstick ngokuphenduka okumbalwa ukuze uvumele umoya ukuba uphume ethangini likawoyela.

- Ngemva kokushintshwa kwamafutha, vumela ikholomu ehlukanisayo iye phezulu naphansi izikhathi ezimbalwa ngaphandle komthwalo.

Lahla uwoyela omdala ngendlela efanele (iphuzu lokulahla uwoyela wendawo). Amafutha amadala akumele athelelwe emhlabathini noma ohlelweni lokudonsa amanzi, noma axutshwe nenye imfucuza.

Amafutha weHydraulic

Sincoma lawa mafutha alandelayo e-hydraulic cylinder ye-hydraulic lic:

- I-Shell Tellus T 22

- I-Aral Vitam Gf 22

- I-BP Energol HLP 22

oda no. 400142 (1 ilitha)

oda no. 400142 (1 ilitha) - I-DTE 11 yeselula

- noma okulinganayo

Ungasebenzisi ezinye izinhlobo zamafutha. Ukusetshenziswa kwanoma yiluphi olunye uhlobo lwamafutha kuzoba nomthelela omubi ekusebenzeni kwe-hydraulic cylinder.

Iziyalezo zokuthutha

Ngaphambi kokuthutha ngakunye

Ngaphambi kokuthutha ngakunye- Hambisa i-blade ehlukanisayo phezulu Cisha idivayisi.

- Vala ikepisi yamafutha.

- Donsa ipulaki yamandla ka-t.

- Khipha ukhuni oluhlukanisiwe Khulula iphinikhodi yokukhiya (E) bese ulungisa isondo lezokuthutha (7) endaweni C ukuze lihambe. Isikhundla D esokugcina kuphela.

- Uma kunesidingo, shwiba ibha yokudonsa (26) phansi. Bamba isibambo (16) bese utshekisa isihlukanisi sezinkuni ngokucophelela ngakuwe.

- Manje ungakwazi ukuthutha kalula isihlukanisi sezinkuni.

- Okokuthutha, isiboneloample, ku-trailer: Ngenkathi wenza kanjalo, vikela isihlukanisi selogi endaweni (b) ehlinzekwe ngamabhande.

- Ezokuthutha ngokhreni: Namathisela intambo endaweni yokuphakamisa (a) ehlinzekelwe le njongo.

- Ungalokothi uphakamise iyunithi ngezibambo zokuthutha (16).

- Qaphela ngokucophelela iyunithi ngokumelene nokusikisela ekusheleleni kude ngaphambi kokuthutha ngakunye.

Isitoreji

Ngaphambi kwesitoreji ngasinye

Ngaphambi kwesitoreji ngasinye- Hambisa i-blade ehlukanisayo phezulu

- Ukushintsha idivayisi ye-f.

- Vala ikepisi yamafutha

- Khipha ipulaki yamandla ka-t

Gcina imishini engasetshenziswa endaweni ekhiyiwe eyomile evikelekile eqhweni nangaphandle kokuthi izingane kanye nabantu abangagunyaziwe bangakwazi ukufinyelela kuzo. Ngaphambi kwesitoreji esinwetshiwe, sicela uqaphele lokhu okulandelayoukwandisa impilo yesevisi yedivayisi ukuze uqinisekise ukusebenza kahle:

- Hlanza kahle idivayisi.

- Hlola idivayisi ukuze uthole izingxenye ezilimele noma ezigugile.

Isiqinisekiso

Sicela ubheke imigomo efakiwe yesiqinisekiso.

Amaphutha angenzeka

![]() Ngaphambi kokuqedwa kwephutha ngalinye:

Ngaphambi kokuqedwa kwephutha ngalinye:

- Ukushintsha idivayisi ye-f.

- Donsa ipulaki yamandla.

Uma kuba namanye amaphutha noma imibuzo sicela uxhumane nomthengisi wangakini.

Idatha yobuchwepheshe

Ukulungiswa kobuchwepheshe kugodliwe!

Amadokhumenti / Izinsiza

|

I-ATIKA ASP 10 TS-2 Log Splitter [pdf] Incwadi Yeziqondiso ASP 10 TS-2, ASP 12 TS-2, ASP 14 TS-2, ASP 10 TS-2 Log Splitter, ASP 10 TS-2, Log Splitter, Splitter |