Ulwazi Lokuphepha

The ATOMSTACK S20 Pro is a Class 4 laser product. Always wear appropriate laser safety goggles when operating the machine. Never look directly into the laser beam. Ensure the work area is well-ventilated to dissipate fumes. Keep children and pets away from the operating machine.

- Always wear laser safety goggles.

- Qinisekisa ukungena komoya ngendlela efanele endaweni yokusebenza.

- Keep clear of the laser path during operation.

- Do not leave the machine unattended while operating.

- Familiarize yourself with the emergency stop button.

Yini EseBhokisini

- ATOMSTACK S20 Pro Laser Engraver Unit

- F30 Pro Air Assist Kit (with dual built-in pumps)

- I-adaptha yamandla

- Ikhebula le-USB

- I-Safety Goggles

- One-step Installation Tools

- Imaniwali yosebenzisayo

- Test Materials (e.g., wood, metal sampkancane)

Umhlahlandlela Wokusetha

Follow these steps to assemble and prepare your ATOMSTACK S20 Pro Laser Engraver for first use.

1. Ukukhumula nokuhlanganisa

Carefully remove all components from the packaging. Refer to the included "One-step Installation Tools" for assembly.

Image: All components of the ATOMSTACK S20 Pro Laser Engraver laid out on a table, including the main frame, laser module, air assist pump, control panel, and accessories.

2. Connecting the Air Assist Pump

The F30 Pro Air Assist Kit is designed to improve cutting performance and reduce charring. Connect the air assist tube to the laser module and the pump unit.

Image: A close-up of the ATOMSTACK F30 Pro Air Assist Pump connected to the laser engraver, showing the tube interface and power input.

3. Ukuxhunywa kwamandla

Xhuma i-adaptha yamandla kuyunithi yokulawula bese uyixhume endaweni yamandla efanelekile.

4. Laser Module Installation and Focusing

Install the laser module onto the gantry. Use the provided focusing tool or adjustable knob to set the correct focal length (typically 4.5mm from the material surface).

Isithombe: A enemininingwane view of the ATOMSTACK S20 Pro laser module, highlighting the adjustable knob used for precise focusing.

Okokufundisa kwevidiyo yokufaka

Video: A step-by-step guide demonstrating the installation process for the ATOMSTACK S20 Pro Laser Engraving Machine.

Imiyalelo yokusebenza

The ATOMSTACK S20 Pro offers multiple operating methods for your convenience.

1. Izindlela Zokusebenza

- Computer USB: Connect the engraver to your computer via USB. Compatible with LightBurn and LaserGRBL software.

- Isikrini sokuthinta: Utilize the built-in offline control touchscreen for direct operation by inserting a TF card with engraved patterns.

- Mobile Phone APP: Use the ATOMSTACK APP (available for Android and Apple) to connect and control the engraver via WiFi.

Image: An illustration showing the three primary connection and control methods for the ATOMSTACK S20 Pro: via Computer USB, directly through the Touch Screen, or wirelessly using a Mobile Phone APP.

2. Offline Engraving via Touchscreen

To perform offline engraving, ensure your TF card contains the desired engraving patterns. Insert the TF card into the control unit. Select "Carve" from the touchscreen menu, choose your file, and initiate the engraving process.

Video: A demonstration of how to achieve offline engraving using the touchscreen interface of the ATOMSTACK S20 Pro.

3. Mobile Phone APP Connection

Download the ATOMSTACK APP from your phone's app store. Connect your mobile phone to the engraver's WiFi network (default password: 12345678). Open the APP, select your engraver, and you can now control it wirelessly.

Video: A guide on connecting the ATOMSTACK S20 Pro to a mobile phone via WiFi and using the dedicated application for control.

4. Engraving and Cutting Materials

The S20 Pro is capable of engraving and cutting a wide variety of materials.

Isithombe: Umbukiso wamakholajiasing various materials that can be engraved or cut by the ATOMSTACK S20 Pro, including wood, metal, acrylic, leather, and more.

5. High Precision Engraving

The 0.08 * 0.1mm laser spot area and 256-bit grayscale ensure high contrast and delicate patterns, especially on metal.

Isithombe: Isikwele view of the laser module, illustrating the 4x6W laser coupling technology that achieves 20W output power and a fine 0.08x0.1mm compressed spot for high-precision engraving.

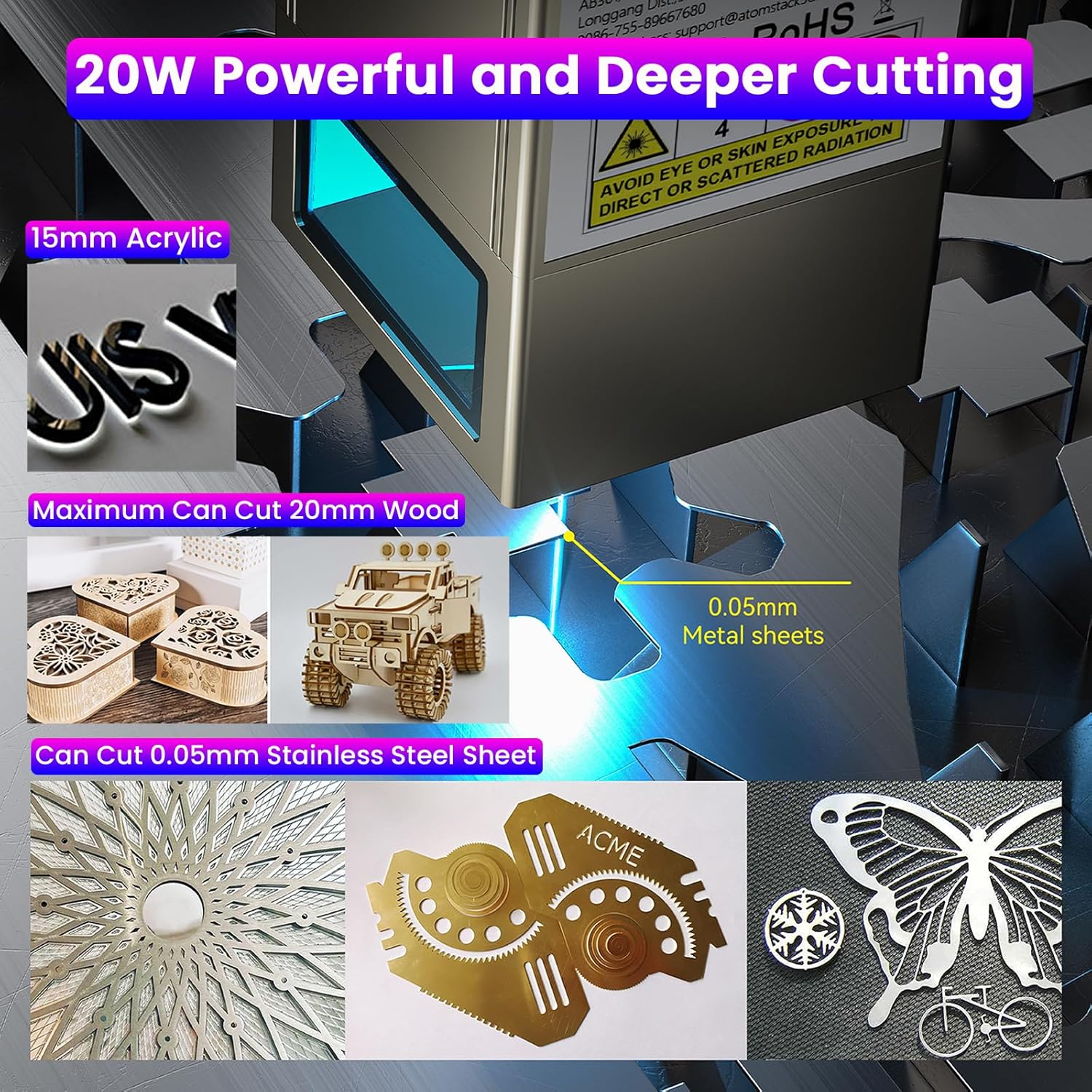

6. Deep and Fast Cutting

With 20000mW output, the S20 Pro can cut 15-20mm thick tung wood and 8-10mm thick black acrylic in one pass. It can also cut 0.05mm stainless steel. The air assist kit significantly enhances cutting speed and edge cleanliness.

Image: The ATOMSTACK S20 Pro demonstrating its powerful cutting capabilities on various materials, including 15mm acrylic, 20mm wood, and 0.05mm metal sheets.

Isondlo

1. Cleaning the Laser Lens

Regularly clean the laser lens with a soft, lint-free cloth and isopropyl alcohol to ensure optimal performance and prevent residue buildup.

2. Gantry and Rail Lubrication

Periodically lubricate the gantry and rails with a small amount of machine oil to ensure smooth movement of the laser module.

3. Air Assist System Check

Inspect the air assist tube and pump for any blockages or damage. Ensure the air filter (if applicable) is clean.

Image: A comparison showing the effect of the air assist pump on cutting quality, with a smooth, clean edge on the left (with air assist) and a burnt, rough edge on the right (no air assist).

Ukuxazulula inkinga

1. Laser Not Firing

- Hlola ukuthi ikhebula likagesi lixhunywe kahle yini.

- Qinisekisa ukuthi inkinobho yokumisa isimo esiphuthumayo ayibandakanyiwe.

- Verify the laser module is correctly installed and connected.

- Confirm the software settings (power, speed) are appropriate for the material.

2. Poor Engraving/Cutting Quality

- Adjust the focal length of the laser. Incorrect focus is a common cause of poor quality.

- Hlanza i-laser lens.

- Increase laser power or decrease engraving/cutting speed.

- Qinisekisa ukuthi impahla ithambile futhi ibekwe kahle.

- Check the air assist system for proper function.

3. Connection Issues (WiFi/USB)

- For WiFi, ensure your device is connected to the engraver's network and the password is correct.

- For USB, ensure the cable is securely connected to both the engraver and the computer. Install necessary drivers if prompted.

- Restart both the engraver and the controlling device.

Customer Testimonial Video

Video: A customer's real-world testing and review of the ATOMSTACK S20 Pro, demonstrating its performance and capabilities.

Imininingwane

| Isici | Imininingwane |

|---|---|

| Inombolo Yemodeli | I-S20 Pro |

| Optical Laser Power | 20000mW (20W) |

| Amandla Omshini | 130W |

| Laser Spot Area | 0.08 * 0.1mm |

| Ibhodi lomama | 32-bit |

| Isikali esimpunga | 256-bit |

| I-Air Assist Kit | F30 Pro (Dual built-in pumps) |

| Max Wood Cutting Thickness | 15-20mm (Tung wood, single pass) |

| Max Acrylic Cutting Thickness | 8-10mm (Black acrylic, single pass) |

| Max Stainless Steel Cutting Thickness | 0.05 mm |

| Ubukhulu bomkhiqizo | 25.98 x 22.36 x 9.33 amayintshi |

| Isisindo sento | 20 amakhilogremu |

Iwaranti kanye Nokusekela

For warranty information, technical support, or further assistance, please refer to the official ATOMSTACK webisayithi noma xhumana nesevisi yamakhasimende ngokuqondile.

The manufacturer is ATOMSTACK, Co, Ltd.

Ukuze uthole izinsiza ezengeziwe nokwesekwa, vakashela ku- ATOMSTACK Official Store.